A method of synthesizing layered hierarchical porous hkust-1 material

A HKUST-1, multi-level pore technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., to achieve good crystal form, reduce reaction diffusion resistance, and increase reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 0.525g of trimesic acid was dissolved in 15ml of ethanol and stirred for 40min until completely dissolved to obtain solution A; 1.093g of Cu(NO) 3 ·3H 2 O was dissolved in 15ml of deionized water and stirred for 20 minutes to obtain solution B; mixed and stirred for 20 minutes with solution A and solution B, then added 0.4346 g of template agent tetradecyl dimethyl tertiary amine and stirred for 30 minutes, then put it into the reaction kettle for reaction at 110 °C After 10 hours, filter with suction, wash with ethanol three times at room temperature for 12 hours each time, and dry in a vacuum oven at 120°C for 10 hours to obtain a layered hierarchical porous HKUST-1 material, which is designated as sample A1.

Embodiment 2

[0040] 0.735g of trimesic acid was dissolved in 17ml of ethanol and stirred for 50min until completely dissolved to obtain solution A; 1.093g of Cu(NO) 3 ·3H 2 O was dissolved in 17ml of deionized water and stirred for 25 minutes to obtain solution B; mixed and stirred for 25 minutes with solution A and solution B, then added 0.6519g of template agent tetradecyl dimethyl tertiary amine and stirred for 45 minutes, then put it into the reaction kettle for reaction at 120°C After 11 hours, filter with suction, wash with ethanol three times at room temperature, each washing time is 13 hours, and dry in a vacuum oven at 130°C for 12 hours to obtain a layered hierarchical porous HKUST-1 material, which is designated as sample A2.

Embodiment 3

[0042] 0.840g of trimesic acid was dissolved in 20ml of ethanol and stirred for 60min until completely dissolved to obtain solution A; 1.093g of Cu(NO) 3 ·3H 2 Dissolve O in 20ml of deionized water and stir for 30min to obtain solution B; mix solution A and solution B for 30min, then add 0.8692g of templating agent tetradecyldimethyl tertiary amine and stir for 60min, put it in a reaction kettle at 150°C for reaction After 12 hours, filter with suction; wash with ethanol for 4 times at room temperature, each washing time is 15 hours, and dry in a vacuum oven at 150°C for 15 hours to obtain a layered hierarchical porous HKUST-1 material, which is designated as sample A3.

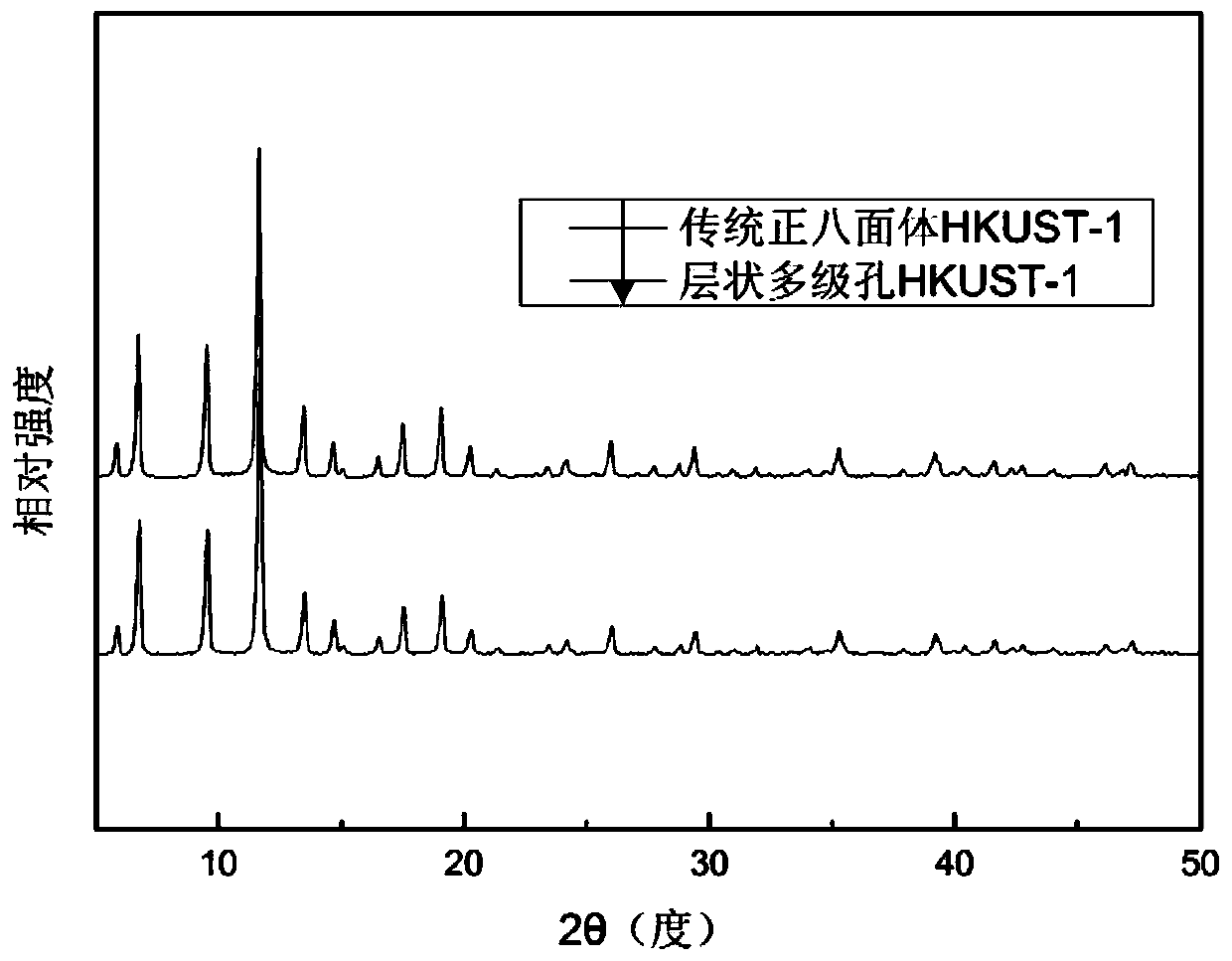

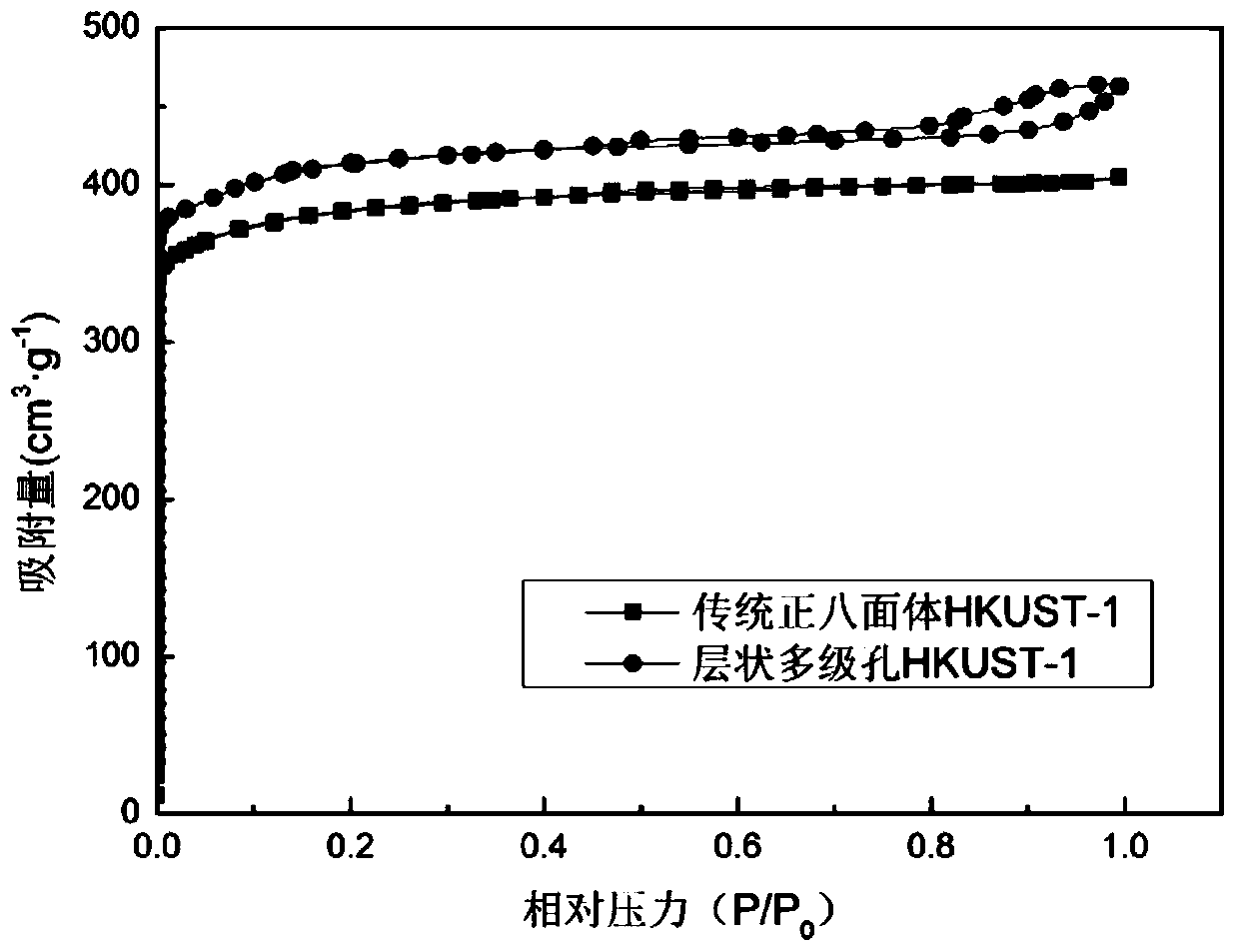

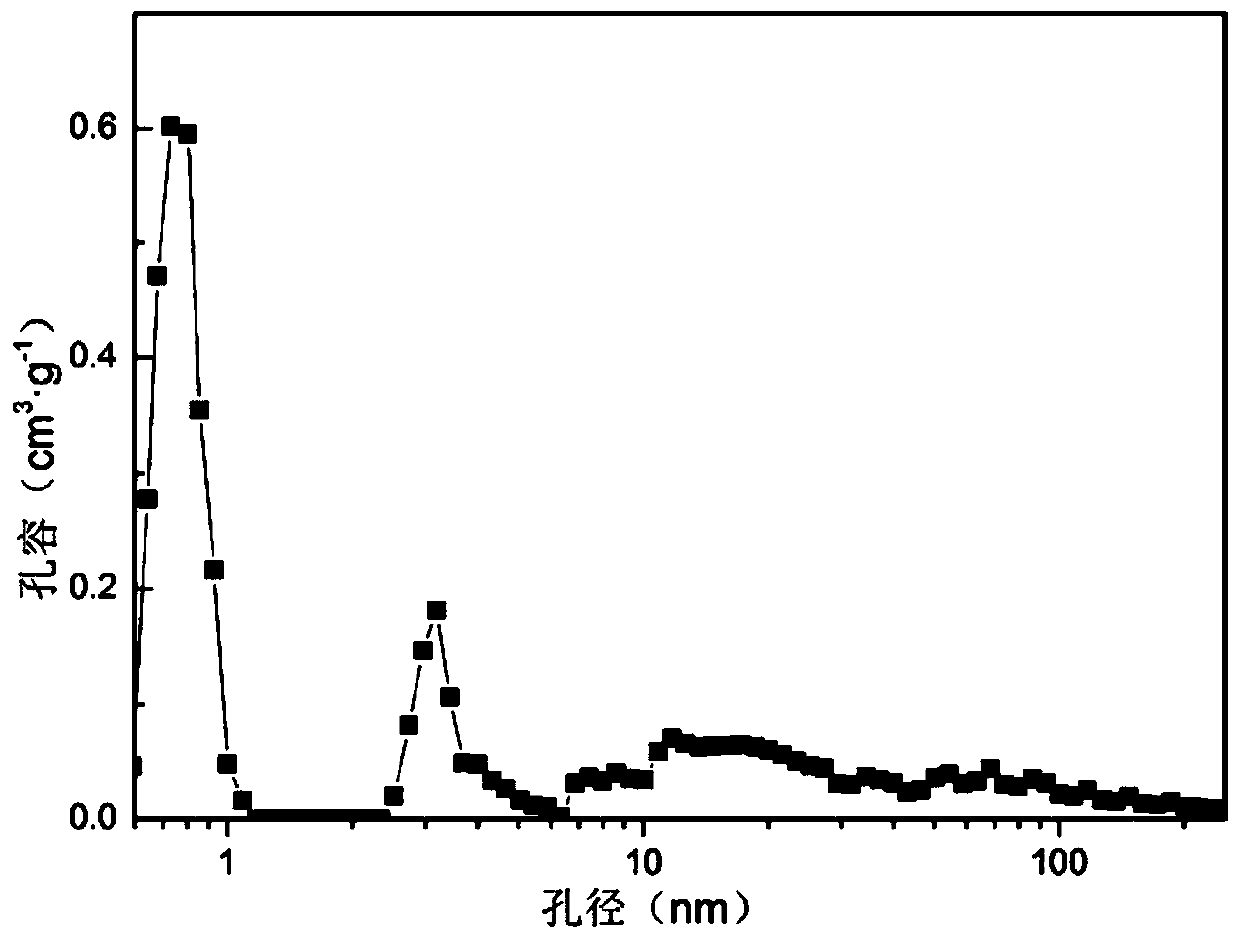

[0043] Taking Example 1 as a representative, the layered hierarchical porous HKUST-1 material prepared in Example 1 was analyzed, and the analysis results of the layered hierarchical porous HKUST-1 material obtained in other examples were basically the same as those in Example 1, but not the same. one provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com