Fire-proof and hydrogen-sulfide-resistance high-pressure hose and preparation method thereof

A hydrogen sulfide-resistant, high-pressure hose technology, applied to chemical instruments and methods, hoses, lamination, etc., can solve problems such as difficult to meet service life requirements, inner tube corrosion, inner tube layer damage, etc., to improve binding tightness Solid effect, strong resistance to hydrogen sulfide corrosion, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

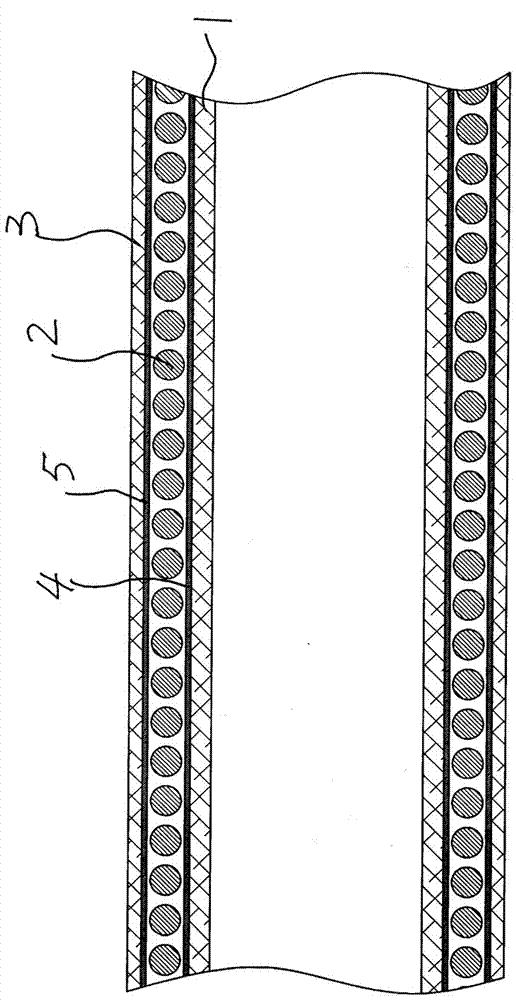

Image

Examples

Embodiment 1

[0052] The components of the inner tube layer consist of: 12 parts by weight of hydrogenated nitrile rubber, 7.5 parts by weight of tetrapropylene fluorine rubber, 2.0 parts by weight of nylon 11, 4.0 parts by weight of weathering agent EPDM rubber and 1.5 parts by weight of rubber The major ingredient that plastic alloy is made of, the filler that the silicon powder that is made of the carbon black of 10 weight parts, the kaolin of 5 weight parts and 3.0 weight parts, the dioctyl phthalate softening agent of 1.2 weight parts, the dioctyl phthalate softening agent of 0.35 weight parts Antiaging agent 4010, dispersant of 0.06 parts by weight, lubricant of 0.03 parts by weight, reinforcing agent of 1.25 parts by weight, accelerator of 0.20 parts by weight and rubber auxiliary agent of 0.12 parts by weight;

[0053]The composition of the fire-resistant and heat-insulating layer is as follows: 13 parts by weight of tetrapropanefluoro rubber, 5.5 parts by weight of nano-alumina fibe...

Embodiment 2

[0057] The composition of the inner tube layer is: 12 parts by weight of hydrogenated nitrile rubber, 8.0 parts by weight of tetrapropanefluoro rubber, 1.5 parts by weight of nylon 11 and 2.0 parts by weight of rubber-plastic alloy. Carbon black, the filler that the kaolin of 5.0 weight parts and the silicon powder of 3.0 weight parts constitute, the dioctyl phthalate softening agent of 1.05 weight parts, the antioxidant RD of 0.45 weight parts, the dispersant of 0.07 weight parts, 0.04 The lubricant of parts by weight, the reinforcing agent of 1.40 parts by weight, the accelerator of 0.20 parts by weight and the rubber auxiliary agent of 0.10 parts by weight;

[0058] The composition of the fire-resistant and heat-insulating layer is as follows: 13 parts by weight of tetrapropanefluoro rubber, 6.0 parts by weight of nano-alumina fiber-reinforced nanomaterials, 6.5 parts by weight of tetrafluoroethylene rubber and 2.50 parts by weight of three The main ingredient of antimony o...

Embodiment 3

[0062] The components of the inner tube layer are: 12 parts by weight of hydrogenated nitrile rubber, 7.0 parts by weight of tetrapropylene fluorine rubber, 1.75 parts by weight of nylon 11, 4.25 parts by weight of weathering agent EPDM rubber and 2.25 parts by weight of rubber The major ingredient that plastic alloy is made of, is made of the filler of the carbon black of 11 parts by weight, the white carbon black of 3 parts by weight, the kaolin of 3 parts by weight, the spray carbon black of 1.0 parts by weight and the silicon powder of 3.0 parts by weight, 1.10 parts by weight The dioctyl phthalate softener of 0.50 parts by weight, the antioxidant RD of 0.50 parts by weight, the dispersant of 0.08 parts by weight, the lubricant of 0.05 parts by weight, the strengthening agent of 1.50 parts by weight, the accelerator of 0.25 parts by weight and 0.11 The rubber auxiliary agent of weight part;

[0063] The composition of the fire-resistant and heat-insulating layer is as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com