Control system and method for sodium citrate desulfuration process

A desulfurization process, sodium citrate technology, applied in the direction of control/regulation system, separation method, non-electric variable control, etc., to achieve the effect of reducing influence, improving precision, and speeding up the corresponding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

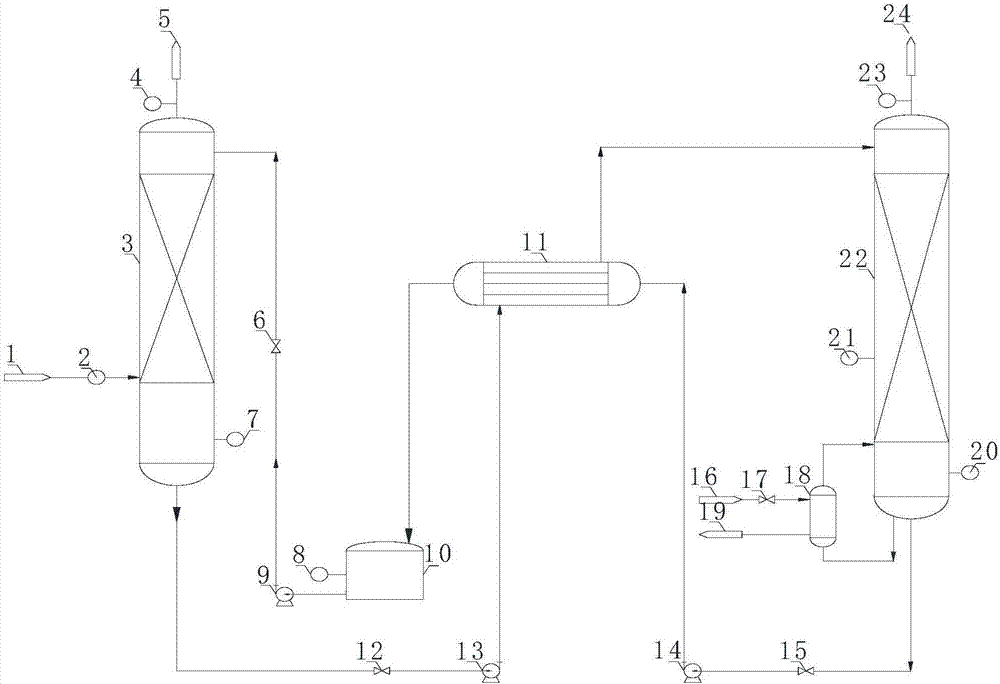

[0030] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

[0031] The control system of the sodium citrate desulfurization process of the present embodiment is as follows in order according to the process flow direction: the flue gas to be treated enters the bottom of the absorption tower 3 from the flue gas inlet 1 through the flue gas feed flowmeter 2, and is connected with the liquid from the storage tank. The sodium citrate absorption liquid flowing out from the sodium citrate absorption liquid storage tank 10 of the level detector 8 and transported to the top of the absorption tower 3 through the sodium citrate absorption liquid delivery pump 9 is fully countercurrently contacted in the absorption tower 3, and the tail gas at the top of the tower After being detected by the exhaust gas detector 4, it is discharged from the outer discharge port 5. The tower still absorbs the rich liquid through the absorbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com