An aluminum foil embossing machine and an aluminum foil container production line

An embossing machine, aluminum foil technology, applied to other household appliances, household appliances, boxes, etc., can solve the problems of increased raw material costs, insufficient stiffness, and insufficient firmness, and achieve increased resistance to deformation, increased slip resistance, and easy removal. put the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

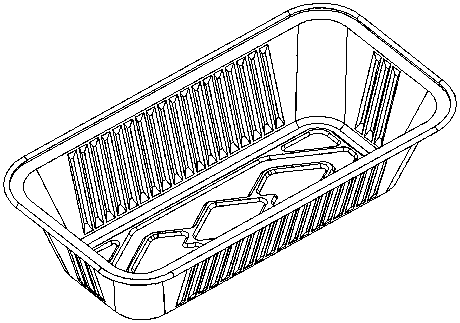

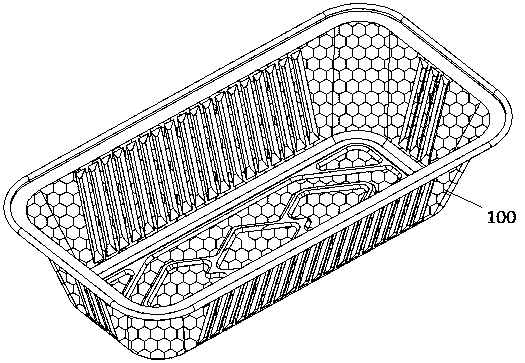

[0037] Such as Figure 7 As shown, the embossed texture adopts dot embossed texture (such as dot embossed texture, ellipse dot embossed texture, grid embossed texture, etc.), after embossing treatment, the embossed texture on the aluminum foil material The coverage area ratio reaches 32% to 39%. Set dotted embossed lines on the aluminum foil container, the rigidity (stiffness) of the embossed aluminum foil container is 7% to 10% stronger than that of the aluminum foil container without embossing, and the durability of the embossed aluminum foil container is higher than that of the aluminum foil container without embossing The durability is enhanced by more than 30%, and even secondary use can be realized (the durability reaches 100%).

Embodiment 2

[0039] Such as Figure 8 As shown, the embossed pattern adopts a flower-shaped / leaf-shaped embossed pattern, and after the embossing treatment, the coverage area ratio of the embossed pattern on the aluminum foil material reaches 24% to 31%. Flower-shaped / leaf-shaped embossed lines are set on the aluminum foil container, the rigidity (stiffness) of the embossed aluminum foil container is 7% to 10% stronger than that of the aluminum foil container without embossing, and the durability of the embossed aluminum foil container is higher than that without embossing The durability of the aluminum foil container is enhanced by more than 30%, and it can even be used twice (the durability reaches 100%).

Embodiment 3

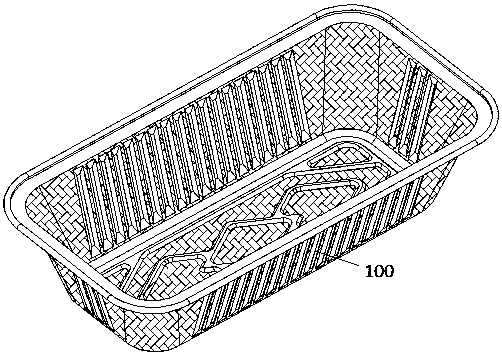

[0041] Such as Figure 9 As shown, the embossed texture adopts geometric embossed texture (the geometric embossed texture is a collection of geometric shapes such as lines, arcs, and wire frames). After embossing, the coverage area of the embossed texture on the aluminum foil material reaches 20%~ 25%. Set geometric embossed lines on the aluminum foil container, the rigidity (stiffness) of the embossed aluminum foil container is 7% to 10% stronger than that of the aluminum foil container without embossing, and the durability of the embossed aluminum foil container is more durable than that of the aluminum foil container without embossing The strength is enhanced by more than 30%, and it can even be used twice (durability reaches 100%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com