A kind of manufacturing method of powder metallurgy gear or pulley

A technology of powder metallurgy and manufacturing method, which is applied in the field of powder metallurgy, can solve the problems of gear or pulley rubber failure, bonding strength affecting the use of parts, low strength and temperature resistance, etc., to achieve increased reliability, reasonable structure and process Practical, the effect of improving strength and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

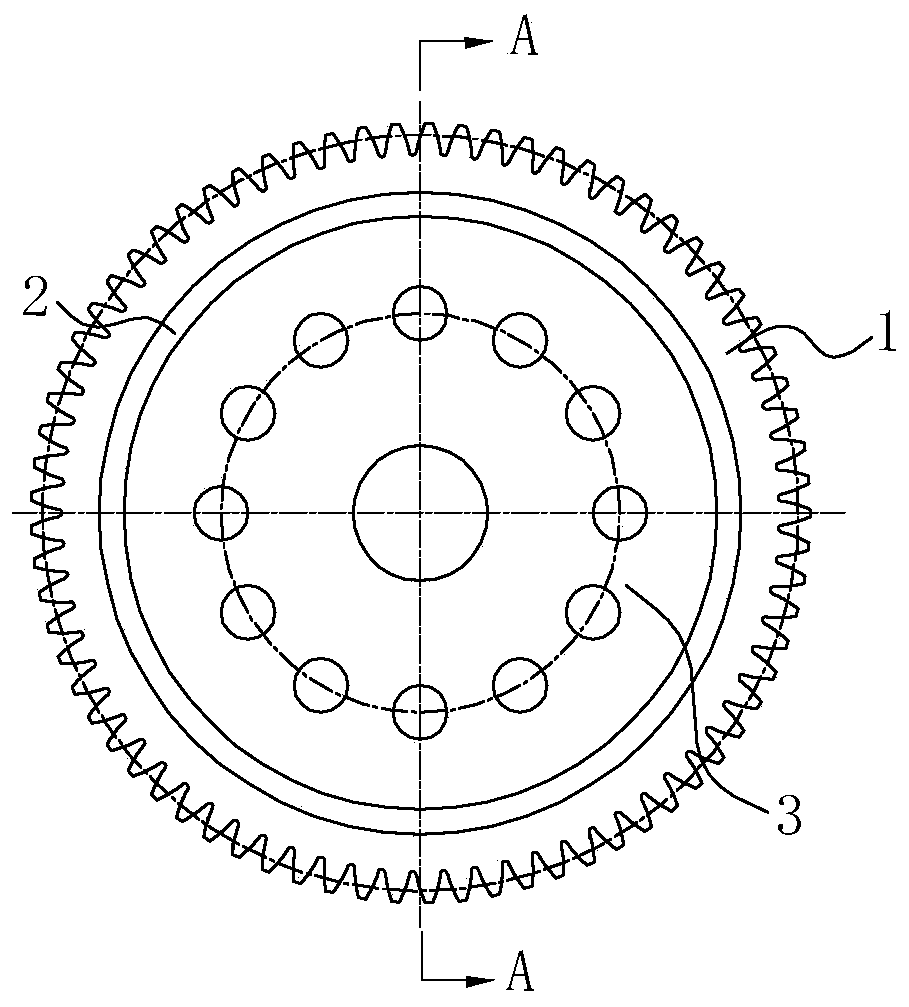

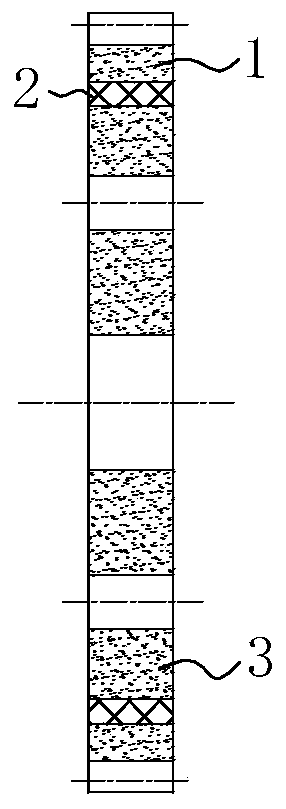

[0041] Such as Figure 1 to Figure 8 As shown, the manufacturing method of the powder metallurgy gear in this embodiment includes the following steps:

[0042] 1) The gear includes an outer layer 1, an inner layer 3, and an intermediate layer 2 arranged between the outer layer 1 and the inner layer 3. The composition of the outer layer 1 is copper: 2%, carbon: 0.8%, nickel: 1.0%, molybdenum : 0.5%, chromium: 1.5%, unavoidable impurities not exceeding 2%, iron: the balance; the middle layer 2 is aluminum foam, and the shape is a ring; the composition of the inner layer 3 is: copper: 2%, carbon : 0.3%, unavoidable impurities not exceeding 2%, iron: balance;

[0043] 2) Fully mix the proportioned inner layer 3 powder and outer layer 1 powder respectively in a mixer to obtain the inner layer 3 mixed powder and outer layer 1 mixed powder, and the inner layer 3 mixed powder and outer layer 1 mixed powder Layer 1 mixed powder has no visible agglomeration and segregation;

[0044] ...

Embodiment 2

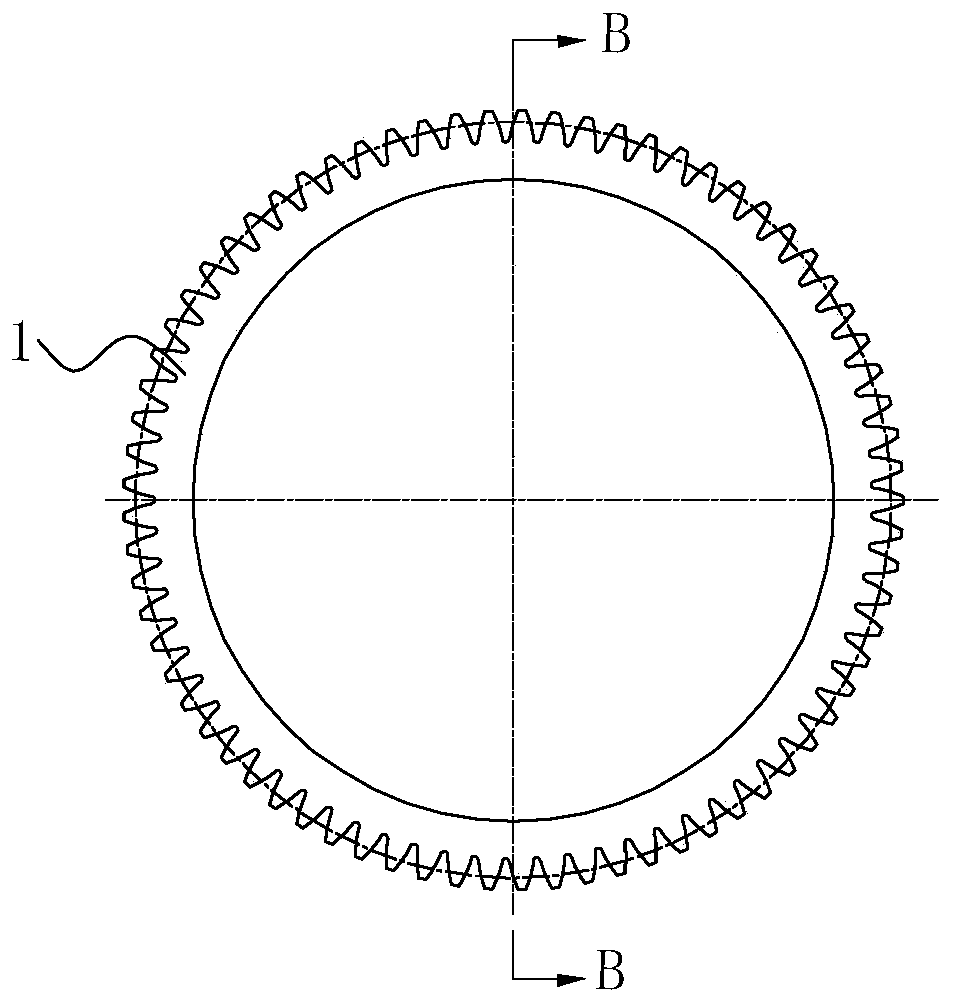

[0051] The manufacturing method of the powder metallurgy pulley in the present embodiment comprises the following steps:

[0052] 1) The pulley comprises an outer layer 1, an inner layer 3 and an intermediate layer 2 arranged between the outer layer 1 and the inner layer 3, wherein,

[0053]The composition of the outer layer 1 is copper: 1%, carbon: 0.3%, nickel: 1.0%, unavoidable impurities not exceeding 2%, iron: the balance; the middle layer 2 is copper foam, and the shape is a ring; the inner layer The composition of layer 3 is: copper: 2%, carbon: 0.7%, nickel: 2.0%, unavoidable impurities not exceeding 2%, iron: balance;

[0054] 2) Fully mix the powders of the inner layer 3 and the outer layer 1 in a mixer to obtain the mixed powder of the inner layer 3 and the mixed powder of the outer layer 1, and the mixed powder of the inner layer 3 and the outer layer 1 The mixed powder has no visible agglomeration and segregation;

[0055] 3) Pressing: Put the mixed powder of th...

Embodiment 3

[0062] The manufacturing method of the powder metallurgy gear in the present embodiment comprises the following steps:

[0063] 1) The gear includes an outer layer 1, an inner layer 3, and an intermediate layer 2 arranged between the outer layer 1 and the inner layer 3. The composition of the outer layer 1 is copper: 2.0%, carbon: 0.8%, nickel: 2.0%, molybdenum : 1.5%, unavoidable impurities not exceeding 2%, iron: the balance; the middle layer 2 is nickel foam and the shape is circular; the composition of the inner layer 3 is: copper: 1.5%, carbon: 0.5%, no Unavoidable impurities exceeding 2%, iron: balance;

[0064] 2) Fully mix the proportioned inner layer 3 powder and outer layer 1 powder respectively in a mixer to obtain the inner layer 3 mixed powder and outer layer 1 mixed powder, and the inner layer 3 mixed powder and outer layer 1 mixed powder Layer 1 mixed powder has no visible agglomeration and segregation;

[0065] 3) Compression: Put the mixed powder of inner la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com