High-stability ultrasonic air floating electric spindle

A high-stability, ultrasonic technology, used in large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problem of affecting the life of components and grinding quality, the fluidity of coolant cannot be guaranteed, and the heat of the electric spindle cannot be evacuated. and other problems, to achieve the effect of improving quality, stable rotation and effective cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] The directional terms mentioned in the following embodiments, such as "up, down, left, right" are only referring to the directions of the drawings, therefore, the directional terms are used for illustration and not for limiting the present invention.

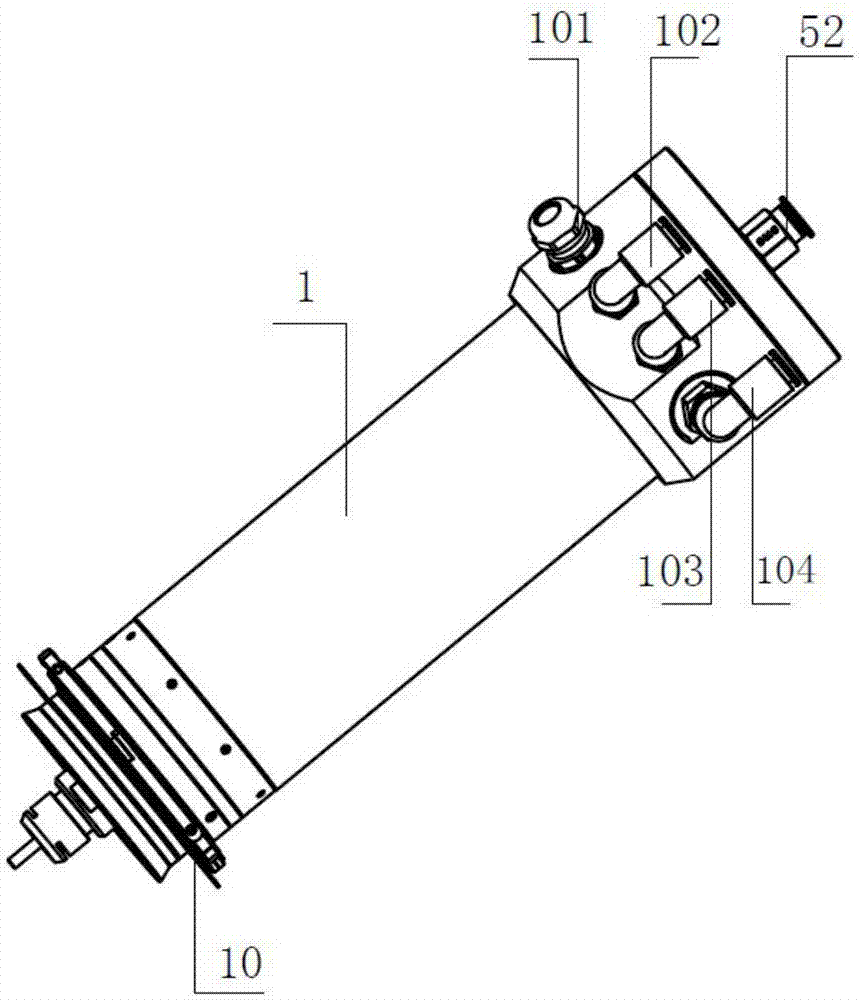

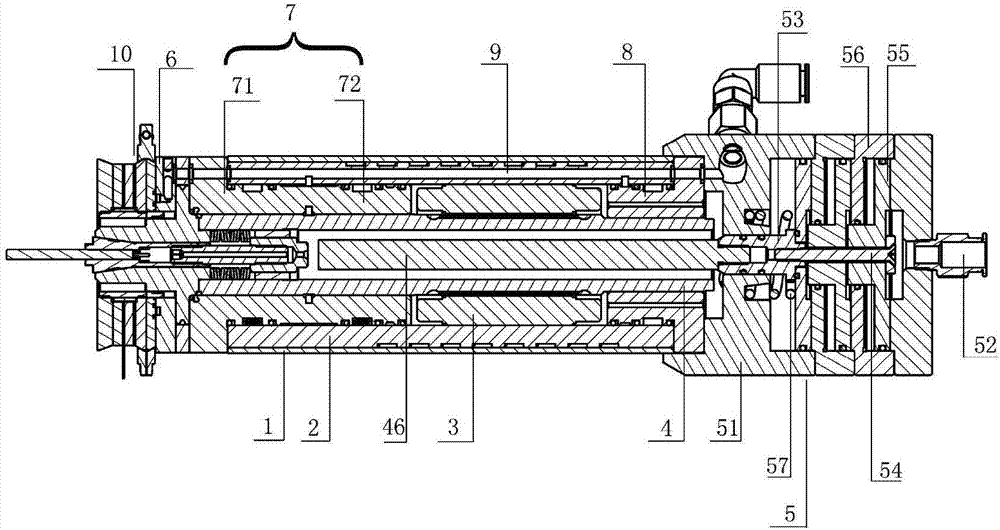

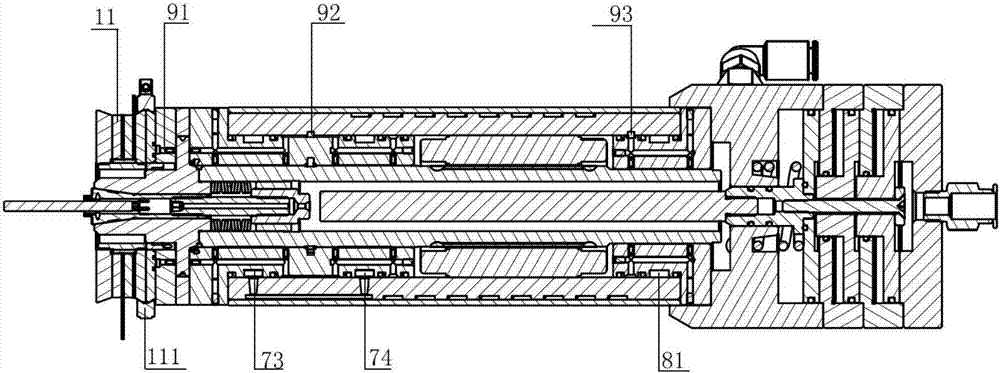

[0022] Such as Figure 1-8 As shown, the high-stability ultrasonic air-floating electric spindle includes the motor spindle body 1, the body liner 2, the stator 3 and the shaft core 4 from the outside to the inside in turn, and the tail of the shaft core is connected to the motor assembly 5; The multi-section bearing provided between the shaft core and the main shaft body 1, the bearing includes a push bearing 6 arranged at the shaft head of the front end of the shaft core 4, the rear end of the shaft core 4 and the stator 3 The rear bearing 8 arranged between and the middle bearing 7 arranged between the front part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com