Wallboard forming device of load bearing wall

A wallboard molding and load-bearing wall technology, applied in auxiliary molding equipment, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of heavy material weight, difficulty in meeting multi-functional quality requirements, and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

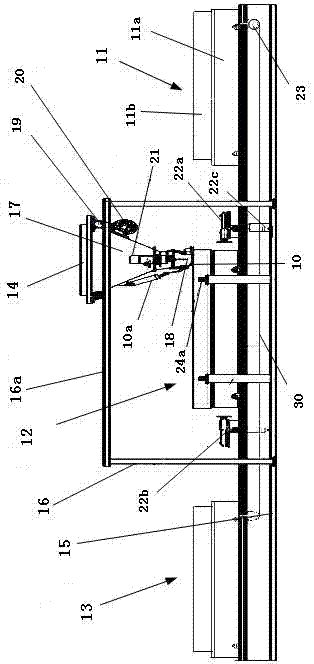

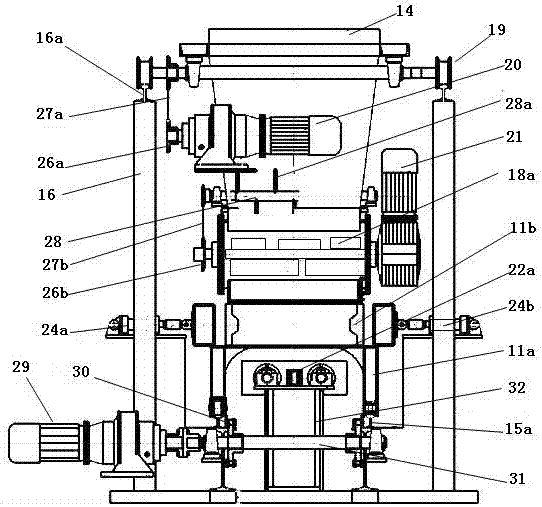

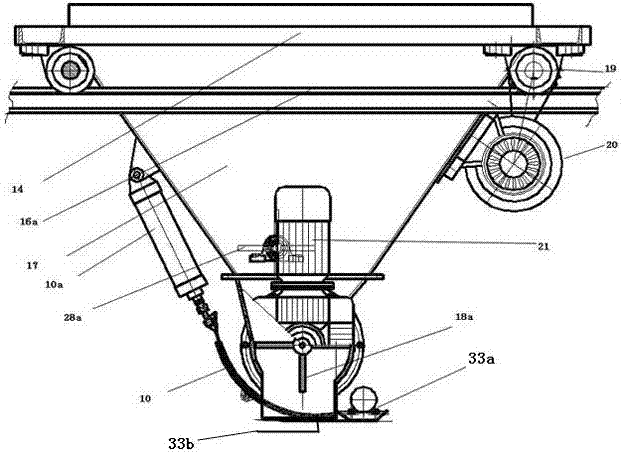

[0019] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings. In the description, the moving direction of the board-making mold is taken as the front-rear direction, and the direction perpendicular to the front-rear direction on a horizontal plane is used as the left-right direction for illustration.

[0020] Explanation of symbols: 10-distributor door, 10a-door opening cylinder, 11-preparation station, 11a-formwork car, 11b-board making mold, 12-board making station, 13-finished product station, 14-hopper car , 15-lower frame, 15a-lower guide rail, 16-upper frame, 16a-upper guide rail, 17-hopper, 18-distributor, 18a-pulling plate, 19-hopper car wheel, 20-hopper car deceleration motor , 21-cloth deceleration motor, 22a-inlet side end push cylinder, 22b outlet side end push cylinder, 22c-lift cylinder, 23-drag chain sprocket, 24a-left side clamp cylinder, 24b-right side side clamp cylinder, 26a-Driving spro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com