Narrow composition control method for free-cutting non-quenched and tempered steel comprising sulfur, aluminum and nitrogen

A non-quenched and tempered steel and control method technology, applied in the field of steelmaking, can solve the problems of multiple production or repeated supplementary production, large deviations in element content, increased production costs and inventory costs, etc., to improve product quality And stability, reduce defective rate, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0020] Examples 1-8: The narrow composition control method of the sulfur-containing aluminum-nitrogen free-cutting non-quenched and tempered steel adopts the following specific processes.

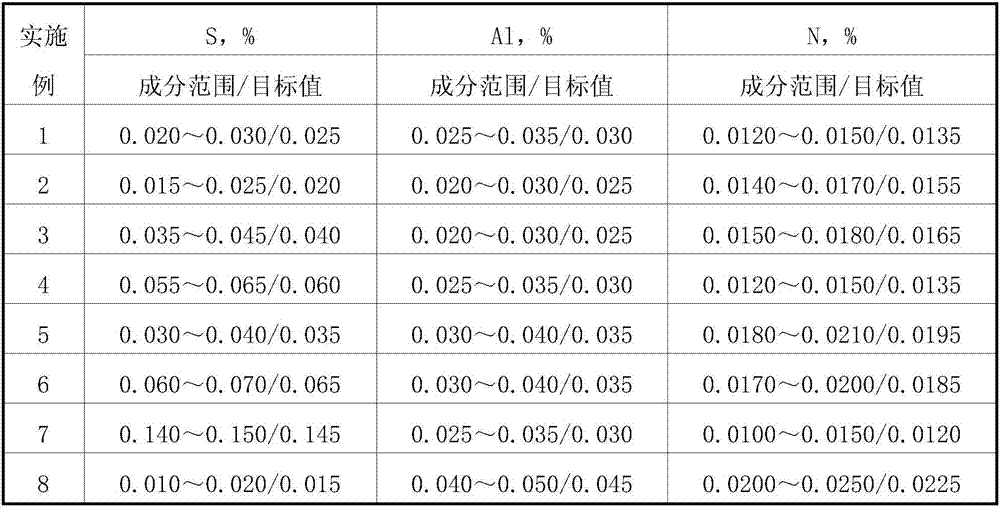

[0021] Table 1: S, Al, N composition range and target value of each embodiment

[0022]

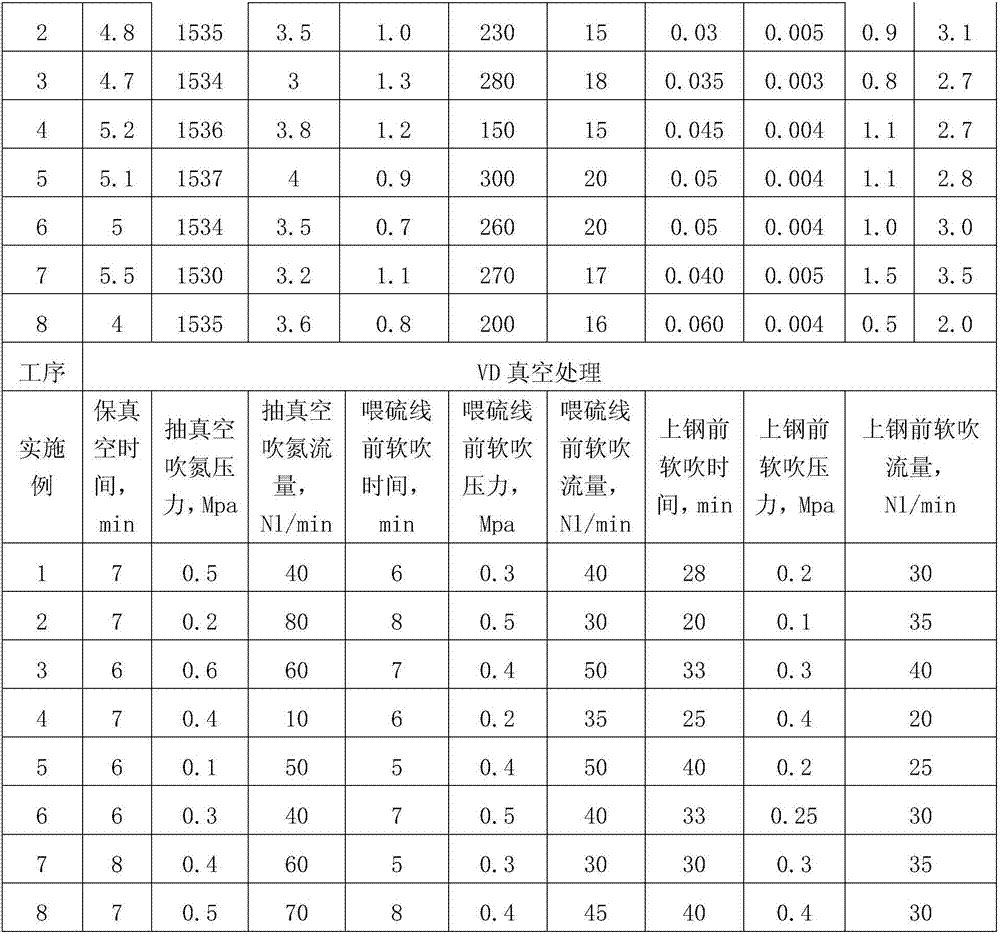

[0023] Table 2: the process technological parameter control of each embodiment

[0024]

[0025]

[0026] The time, pressure and flow rate of soft blowing before steel loading in Table 2 are the time, pressure and flow rate of soft blowing of argon after the above-mentioned sulfur feeding line.

[0027] Table 3: Narrow component control results of each embodiment

[0028]

[0029]

[0030] The above examples prove that the implementation of the technical solution can meet the narrow composition control ranges of S, Al, and N contents whose upper limit minus lower limit is 0.010%, 0.010%, and 0.0030%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com