Using method of automatic water drainage system for hydraulic engineering construction

An automatic drainage and water conservancy engineering technology, applied in water conservancy engineering, water conservancy engineering equipment, marine engineering and other directions, can solve the problems of difficult construction, waste of water resources, affecting the safety of the lock body, etc., to reduce water resources loss, simple structure, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

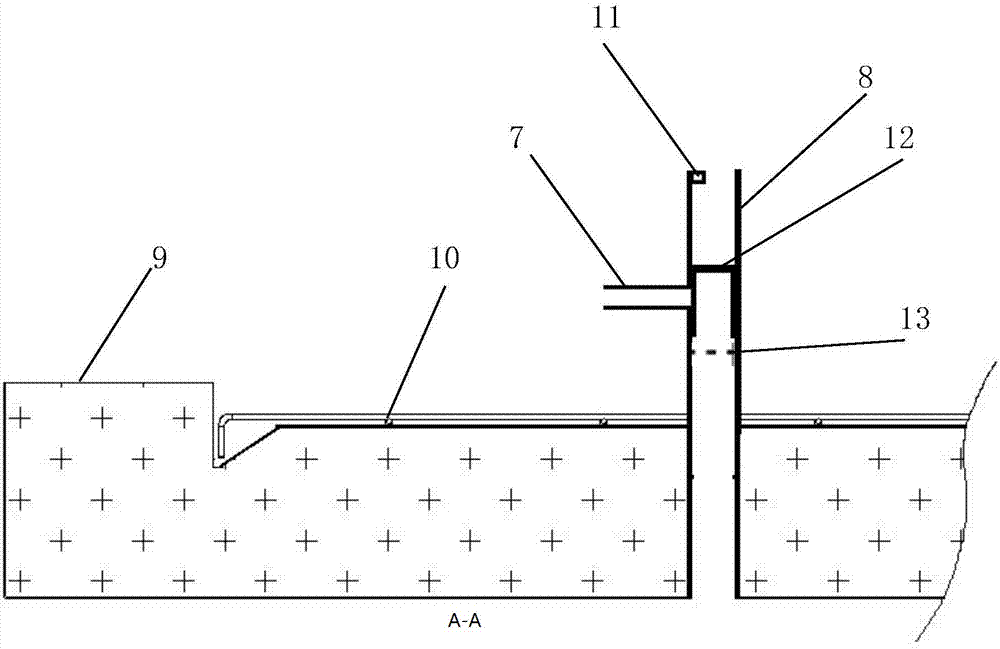

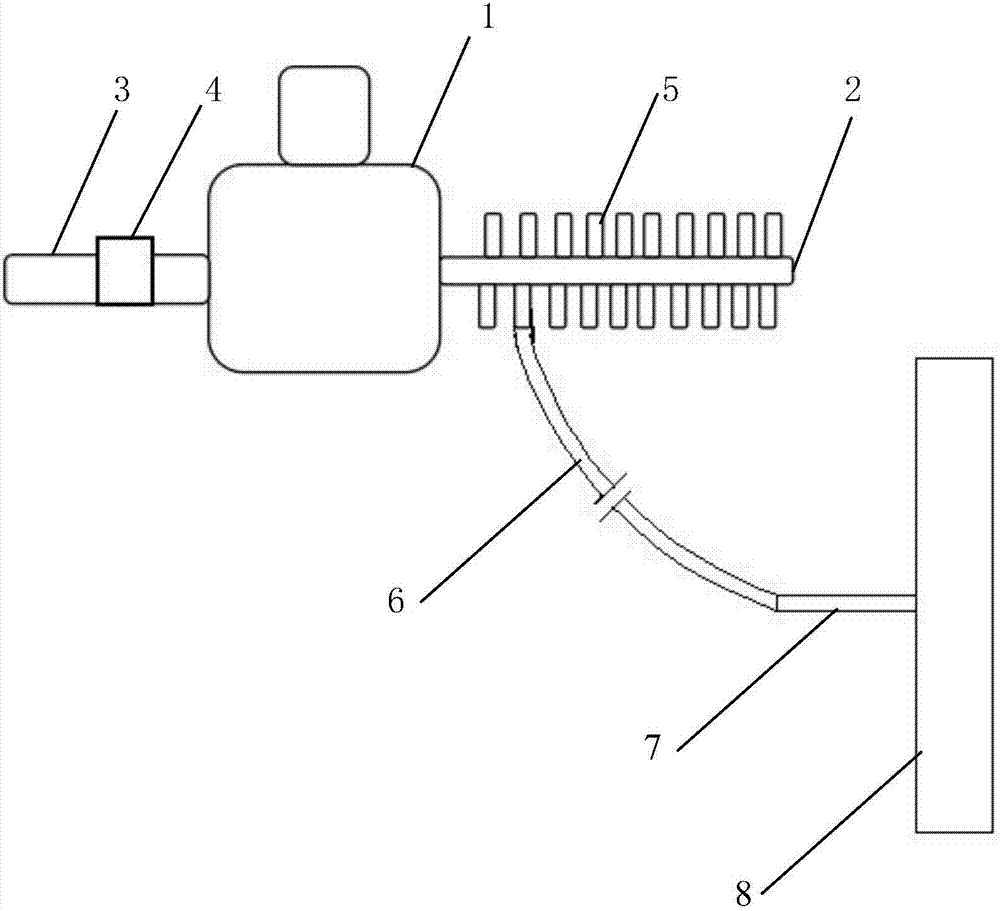

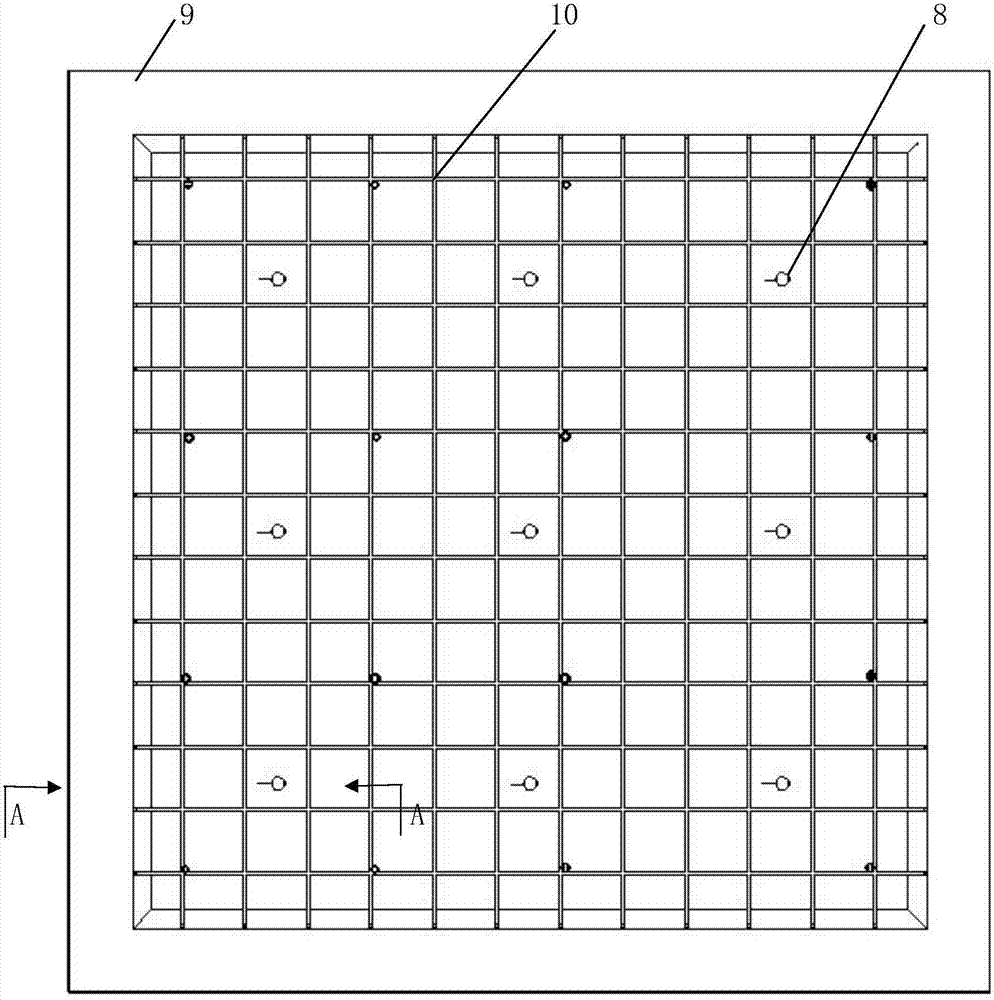

[0026] Embodiment, with reference to accompanying drawing: a kind of automatic drainage system for water conservancy project construction, comprises water pump 1 and water collecting pipe 8, described water pump 1 is provided with PLC control board and water inlet pipe 2, water outlet pipe 3, described PLC control board A wireless receiving module is provided, and the water inlet pipe 2 is provided with a plurality of sub-water inlet pipes 5, and the sub-water inlet pipes 5 are respectively connected to the water suction pipes 6, and each water suction pipe 6 is connected to the water suction joint 7 of the corresponding water collection pipe 8. The water collecting pipe 8 is arranged at the seepage place.

[0027] Further, the water collecting pipe 8 is vertically arranged, and a horizontal water pumping joint 7 is provided in the middle, and the water pumping joint 7 is connected with the water pumping pipe 6. A grid 13 is arranged under the inner hole of the water collecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com