Non-aqueous lithium ion battery electrolyte and lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of non-aqueous lithium-ion battery electrolyte and lithium-ion battery, can solve problems such as battery capacity reduction, consumption of electrolyte, lithium precipitation, etc., and achieve increased ionic conductivity and uniform current distribution , the effect of high lithium ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

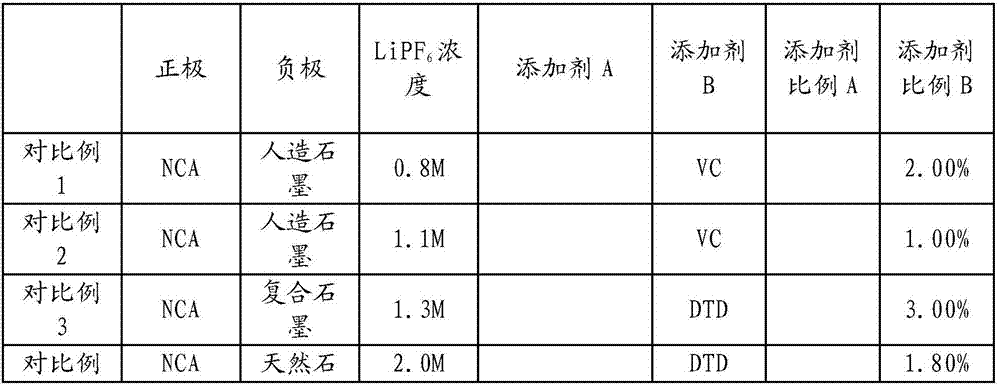

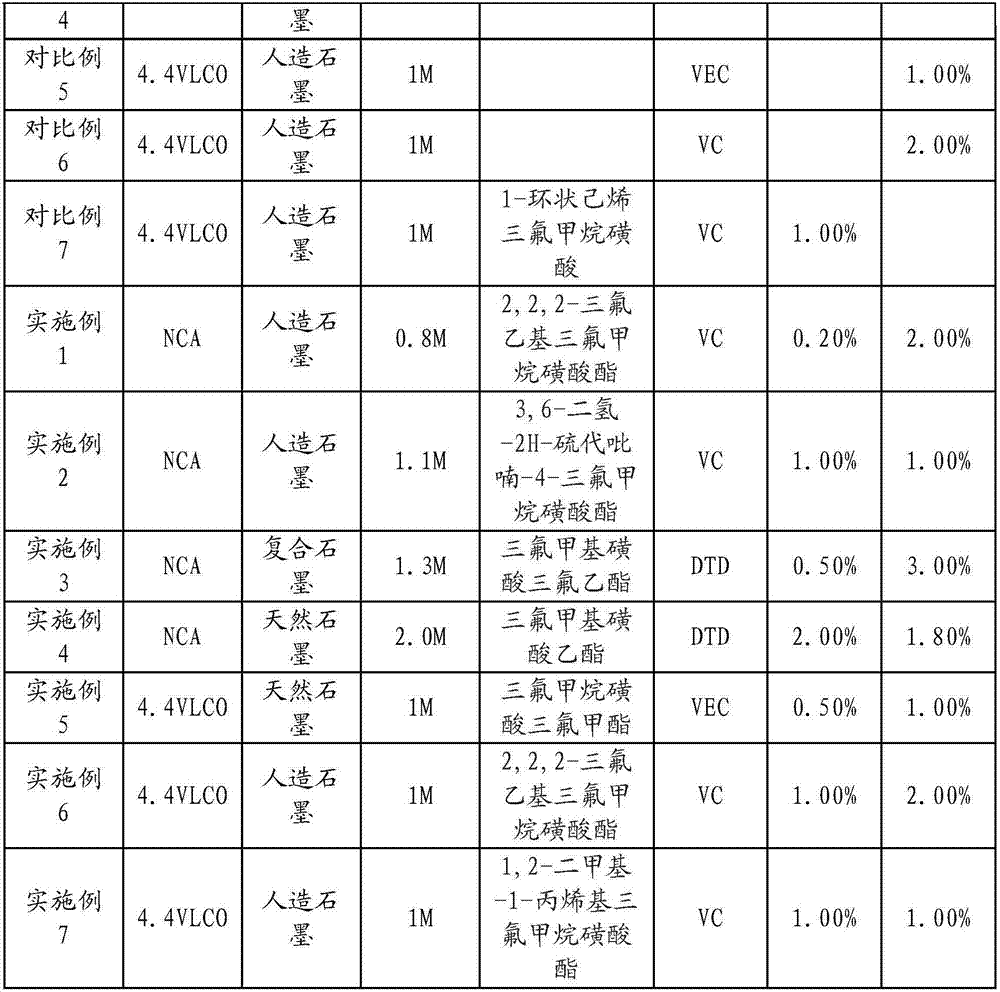

Examples

Embodiment 1

[0031] 1. Electrolyte preparation: The electrolyte is prepared in a BRAUN glove box filled with nitrogen gas with a purity of 99.999%, the moisture in the glove box is controlled at ≤5ppm, and the temperature is room temperature. Mix the solvent system with a mass ratio of EC:DMC:DEC=3:3:4 evenly, seal it, put it in the refrigerator until it is cooled to 8°C, transfer it to the glove box, and then add LiPF in two batches 6 Fully mix to form the non-aqueous electrolyte of the lithium ion battery with a lithium salt molar concentration of 0.8mol / L, add 2,2,2-trifluoroethyl trifluoromethanesulfonate to the above non-aqueous electrolyte to obtain The non-aqueous electrolytic solution containing 0.2% of 2,2,2-trifluoroethyl trifluoromethanesulfonate is uniformly mixed to obtain the non-aqueous lithium ion battery electrolytic solution.

[0032] 2. Preparation of lithium-ion battery positive electrode: Mix nickel-cobalt-aluminum ternary material NCA, conductive agent SuperP, and adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com