Treatment system for high-concentration organic waste gas

A technology of organic waste gas and treatment system, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., to achieve the effects of strong flexibility, full utilization of heat, and excellent purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

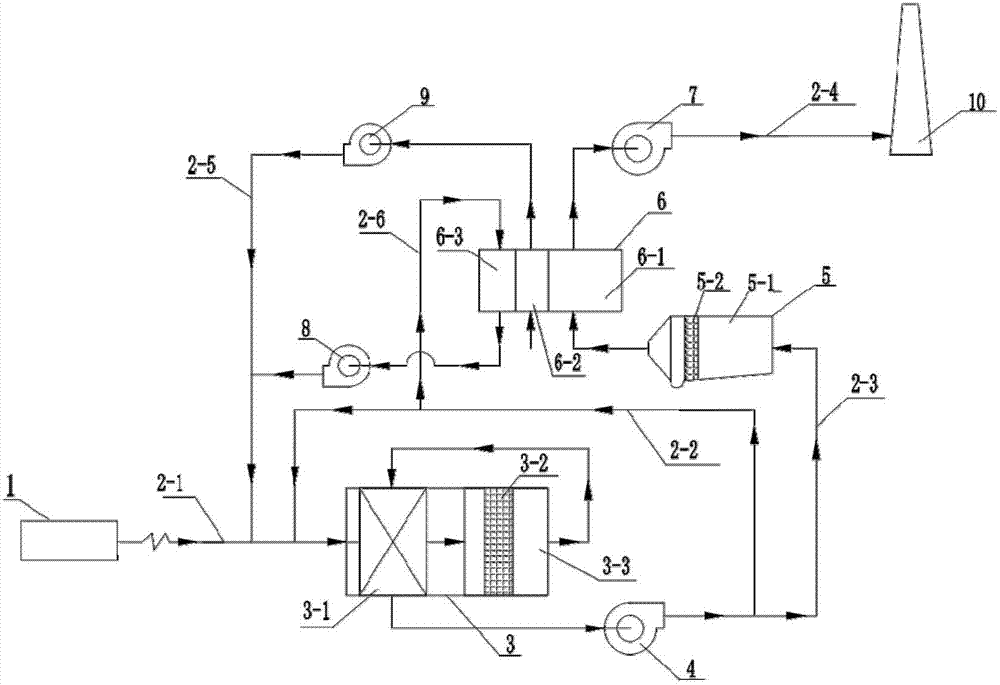

[0039] Such as figure 1 As shown, the pipeline connection and working process of the above treatment system can be:

[0040]The high-concentration exhaust gas directly enters the heat-exchanging CO treatment device through the pipeline, and the exhaust gas at the inlet is heated up by the multi-stage preheating heat exchanger inside the CO device to reach the optimal catalytic reaction temperature. The high-temperature gas after the catalytic oxidation reaction is used as the heat source of the heat exchanger to preheat the gas at the inlet to achieve heat recovery.

[0041] Driven by the No. 1 negative pressure fan connected to the gas outlet, the heat exchange CO starts to work and discharges high-temperature gas. The outlet of No. 1 fan is divided into three ways: the first way is connected to the inlet of the water cooler, and the gas entering the molecular sieve adsorption and desorption device of the back-end processing module is cooled by water to ensure the normal ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com