A method for utilizing backwater before a copper-molybdenum ore dressing plant

A technology of copper-molybdenum ore and copper-molybdenum, which is applied in the direction of solid separation, etc., can solve the problems of increased mutual content of metal elements, excessive harmful elements in products, and reduced recovery rate of metal elements, so as to achieve "zero" discharge and reduce backwater Dealing with investment and production cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

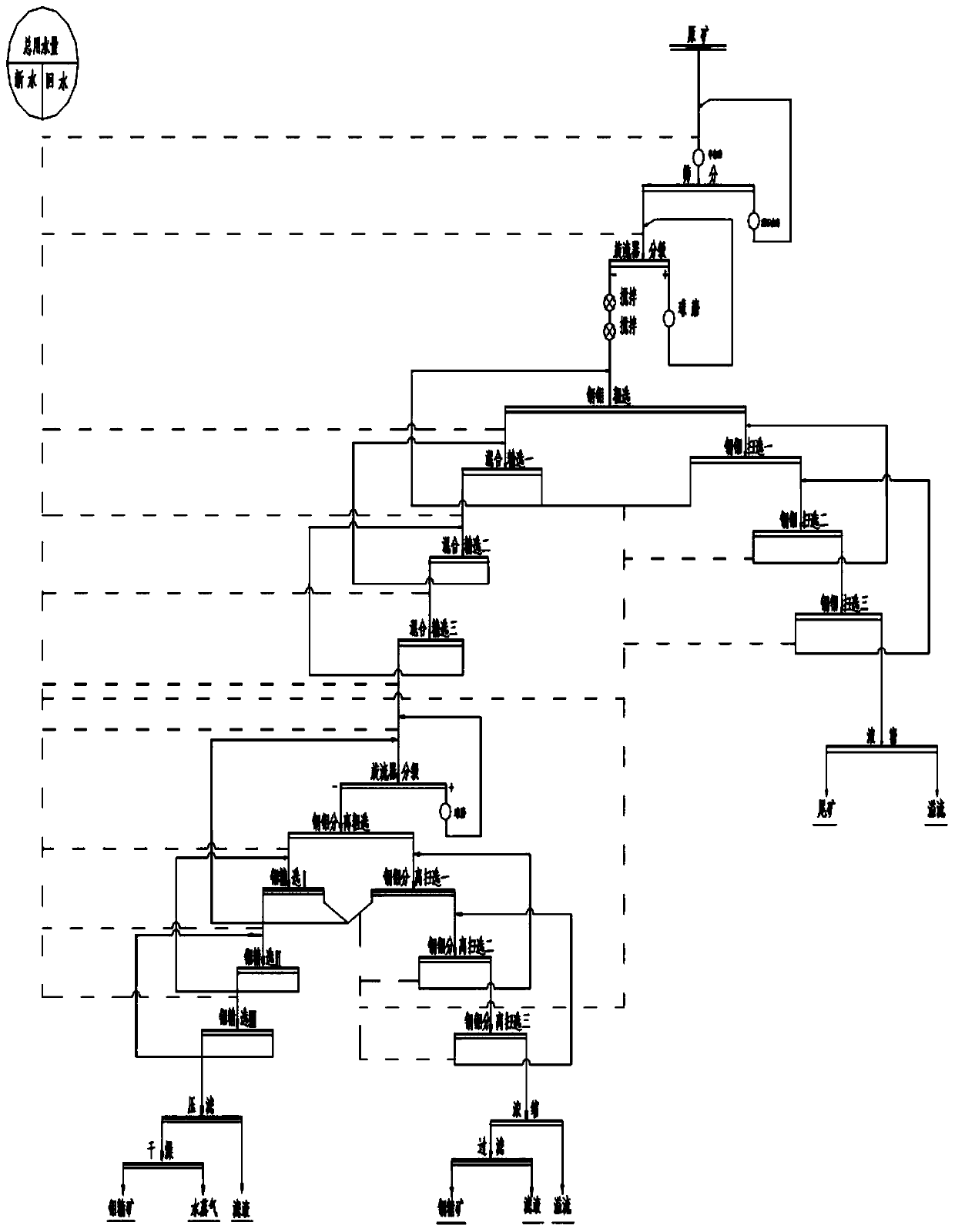

[0018] The method for utilizing backwater before the copper-molybdenum ore dressing plant, the beneficiation process of the copper-molybdenum ore dressing plant is as follows: the raw ore is mixed and roughed with copper and molybdenum after being classified by semi-autogenous ball milling, and then mixed and selected in three stages respectively Three-stage mixed scavenging, three-stage mixed and selected output copper-molybdenum mixed concentrate, three-stage mixed scavenging produces total flotation tailings; copper-molybdenum mixed and selected concentrate enters copper-molybdenum separation flotation; the copper-molybdenum mixed concentrate The separation and flotation process is as follows: after rough separation of copper and molybdenum, three-stage molybdenum concentration and three-stage copper-molybdenum separation and scavenging are carried out respectively. Molybdenum concentration produces molybdenum concentrate, and copper-molybdenum separation and scavenging produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com