Method for forming arc groove in metal plate by adopting laser flexible bending forming technology

A metal plate, bending forming technology, applied in the field of mold-free flexible forming, laser flexible bending forming arc groove, can solve the problems of high forming cost, difficult fast manufacturing, difficult and other problems, and achieve easy flexible manufacturing and save mold manufacturing Cost, the effect of rapid manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: A single-curvature arc groove sample is formed by laser bending of a metal plate.

[0021] (1) Use a shearing machine to cut the metal composite plate with a thickness of 1mm into a rectangular sample with a width of 50mm and a length of 100mm;

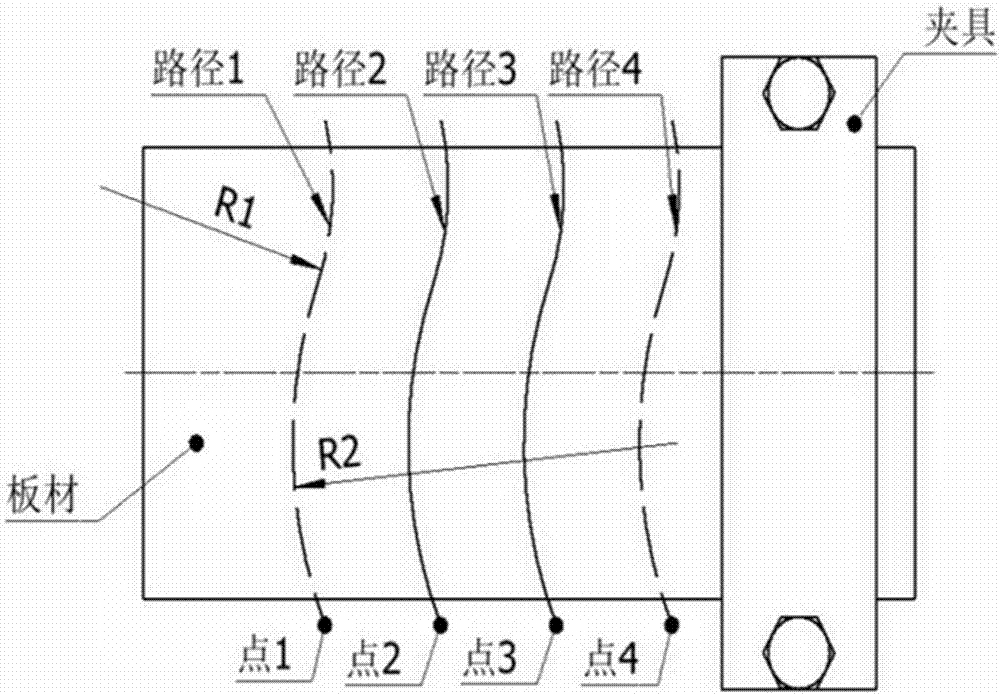

[0022] (2) Use the fixture to clamp one end of the sample and place it on the laser processing table, adjust the laser power to 140w, the frequency to 40Hz, the pulse width to 2ms, and the laser scanning speed to 400mm / min, and then figure 2 At path 1, starting from point 1 outside the edge of the plate, scan and bend back and forth along the circular arc path. In order to stabilize the laser light source during plate processing, reserve a vacant distance, and point 1 outside the edge is 3mm away from the plate. The laser scanning arc radius R is 50mm, the laser reciprocating scanning is 20 times in total, the side blowing auxiliary gas N2, the blowing pressure is 0.2MPa, and cooling is 10s after each scanning; ...

Embodiment 2

[0026] Example 2: Laser bending forming of a metal plate with two arc-shaped grooves in opposite directions of curvature.

[0027] It is different from Example 1: step (1) utilizes a shearing machine to cut the metal composite plate sheet material with a thickness of 1mm into a rectangular sample with a width of 80mm and a length of 100mm;

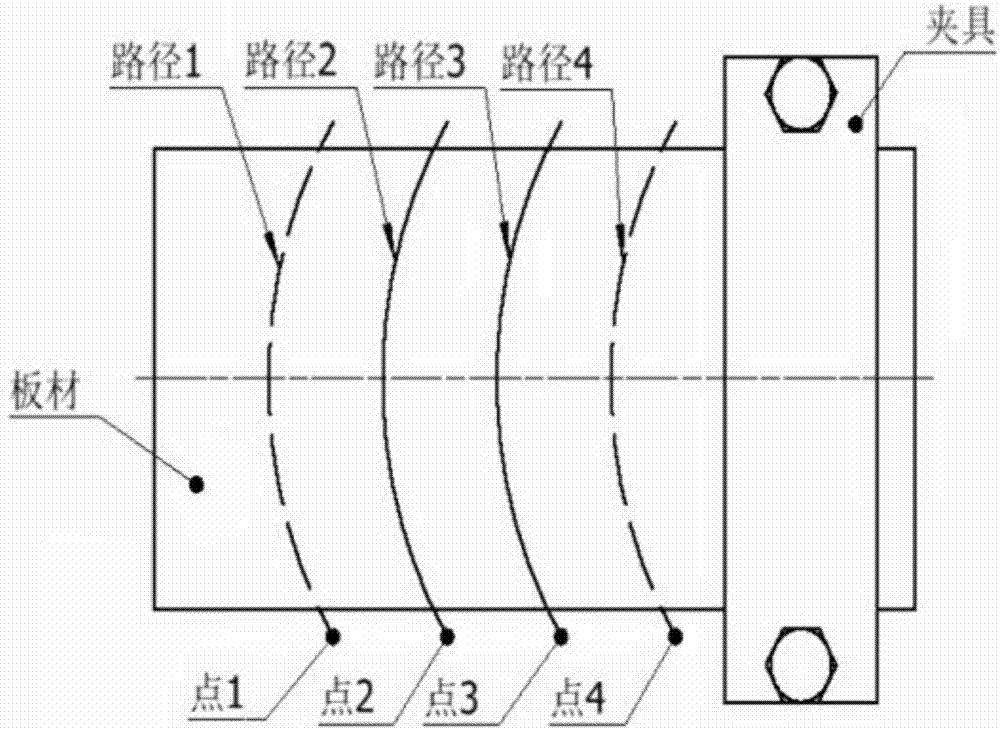

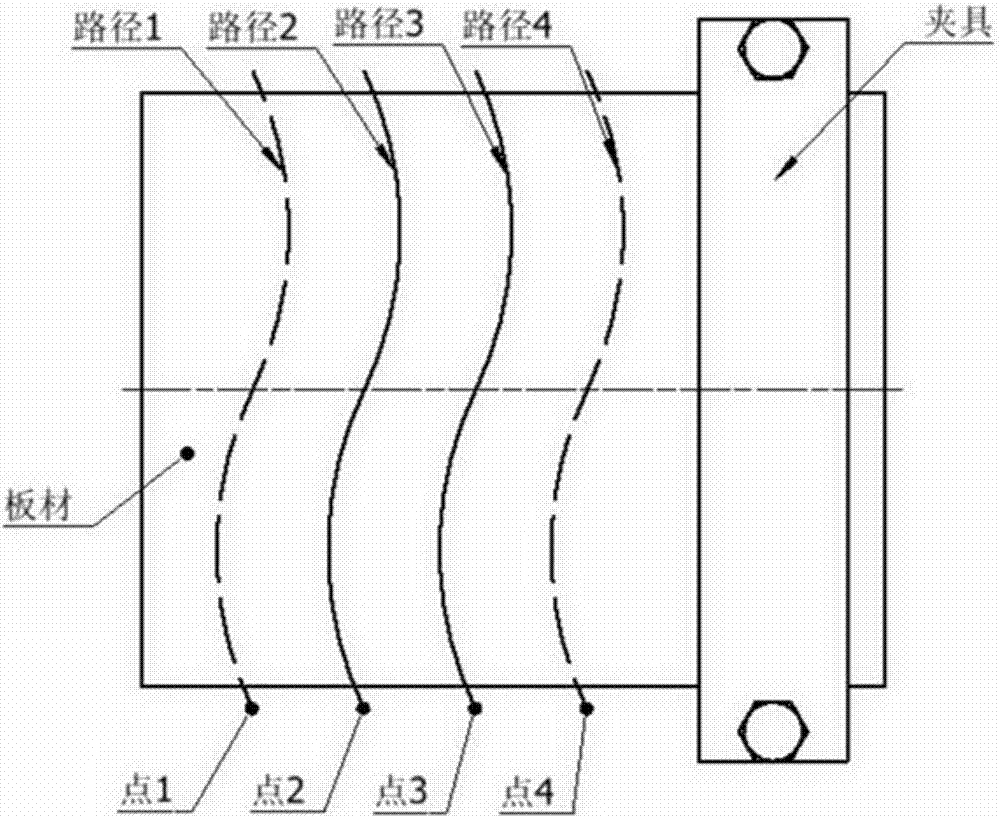

[0028] The second difference from Embodiment 1: the laser bending scanning path is different. In Example 2, the laser scanning path is two arcs with opposite curvature directions, such as image 3 As shown, the radius of the arc is 50mm, and the other steps are the same as in Example 1.

[0029] According to the results of Examples 1 and 2, the shape of the groove of the forming sample can be generalized for forming complex curved grooves such as B-spline curves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com