Copper-gluconate preparing method and copper gluconate prepared with method

A technology of copper gluconate and gluconolactone, applied in the field of copper gluconate, can solve the problems of high production cost, high product quality, high solubility of copper gluconate, temperature insensitivity, etc., and achieves good product quality, simple production equipment, and reduced Effect of Crystallization Cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

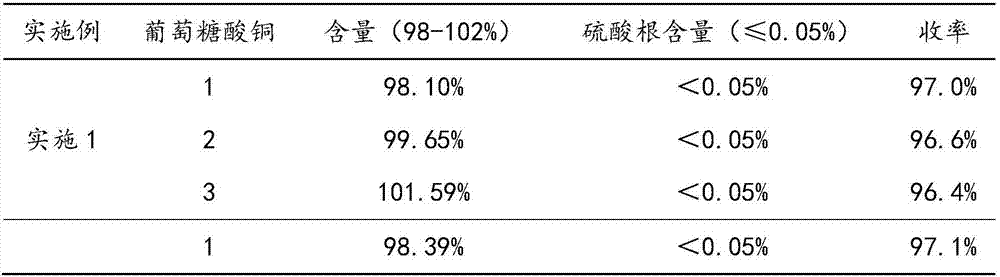

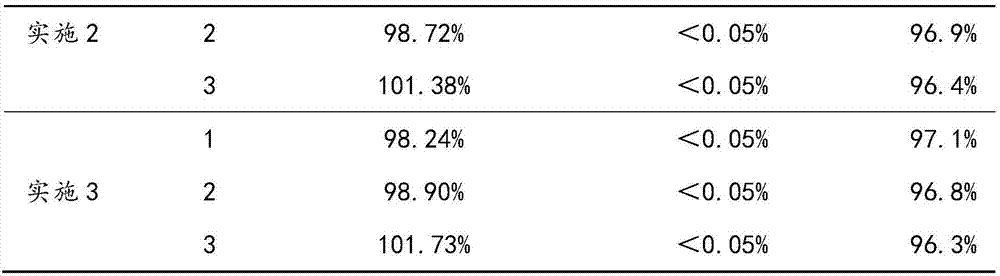

Examples

Embodiment 1

[0029] In this embodiment, the parts by weight for preparing the copper gluconate raw material are: 1 part of copper nitrate; 1 part of potassium carbonate; 1.1 parts of basic copper carbonate; 1 part of gluconolactone.

[0030] Its preparation method comprises the following steps:

[0031] (1) When 1 part of copper nitrate is dissolved in 500 mL of water, heat it to 60° C. and stir the mixed solution for 1 hour, then filter the impurities to obtain a blue transparent copper nitrate solution.

[0032] (2) Dissolve 1 part of potassium carbonate in 250 mL of water and stir until completely dissolved to obtain potassium carbonate solution.

[0033] (3) The potassium carbonate solution was slowly added to the copper nitrate solution, heated to 60° C., and stirred for 1 hour to produce a light green precipitate.

[0034] (4) filter the light green precipitate, then disperse the light green precipitate in 600mL water, heat to 60°C, stir for 20 minutes, then filter and wash to obtai...

Embodiment 2

[0041] In this embodiment, the parts by weight for preparing the copper gluconate raw material are: 1 part of copper sulfate; 1.15 parts of sodium carbonate; 1.2 parts of basic copper carbonate; 1 part of gluconolactone.

[0042] Its preparation method comprises the following steps:

[0043] (1) When dissolving 1 part of copper sulfate in 500mL of water, heat it to 60°C while stirring the mixture for 1 hour, then filter the impurities to obtain a blue transparent copper sulfate solution.

[0044] (2) Dissolve 1.15 parts of sodium carbonate in 250 mL of water and stir until completely dissolved to obtain a sodium carbonate solution.

[0045] (3) The sodium carbonate solution was slowly added to the copper sulfate solution, heated to 60° C., and stirred for 1 hour to produce a light green precipitate.

[0046] (4) filter the light green precipitate, then disperse the light green precipitate in 600mL water, heat to 60°C, stir for 20 minutes, then filter and wash to obtain the pu...

Embodiment 3

[0053] In this embodiment, the parts by weight for preparing the copper gluconate raw material are: 1 part of copper nitrate; 1 part of sodium carbonate; 1.2 parts of basic copper carbonate; 1 part of gluconolactone.

[0054] Its preparation method comprises the following steps:

[0055] (1) When 1 part of copper nitrate is dissolved in 500 mL of water, heat it to 60° C. and stir the mixed solution for 1 hour, then filter the impurities to obtain a blue transparent copper nitrate solution.

[0056] (2) Dissolve 1 part of sodium carbonate in 250 mL of water and stir until completely dissolved to obtain a sodium carbonate solution.

[0057] (3) The sodium carbonate solution was slowly added to the copper nitrate solution, heated to 60° C., and stirred for 1 hour to produce a light green precipitate.

[0058](4) filter the light green precipitate, then disperse the light green precipitate in 600mL water, heat to 60°C, stir for 20 minutes, then filter and wash to obtain the purif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com