Closed water sealed well and drainage system for oil and gas field with sulfur

A closed water and oil and gas field technology, applied in waterway systems, sewer pipeline systems, drainage structures, etc., can solve the problems of poor sealing and poor safety of water-sealed wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

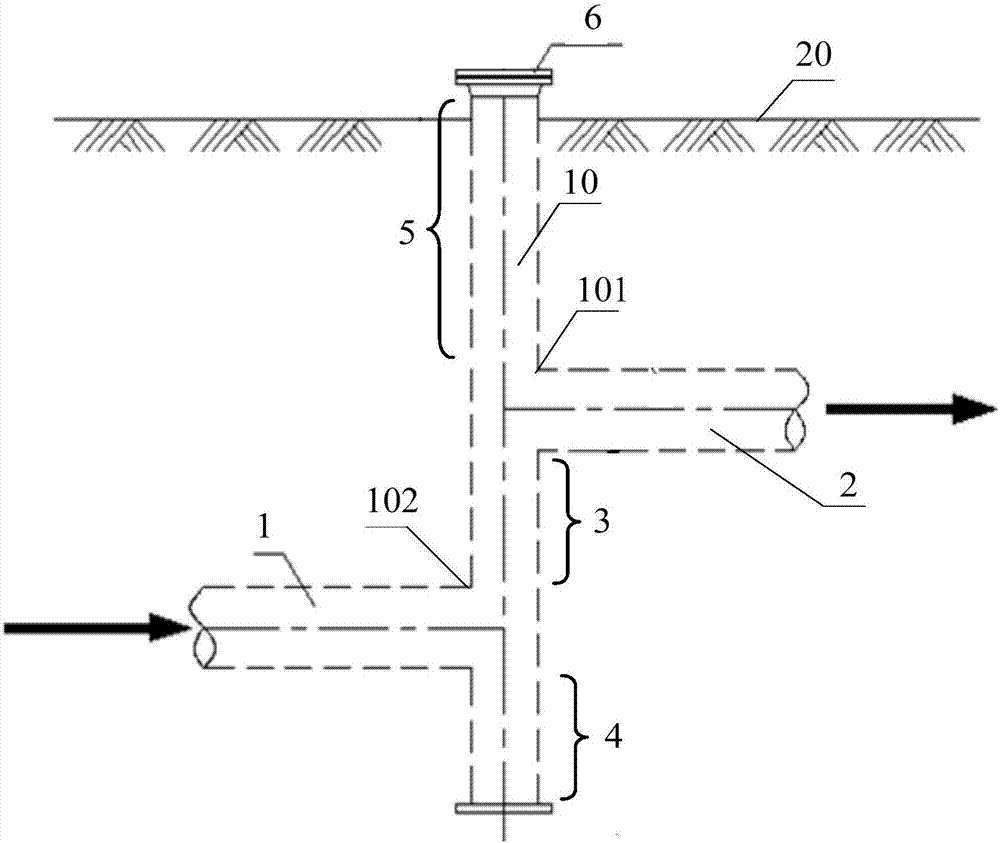

[0049] figure 1 A schematic structural diagram of a closed water-sealed well used in a sulfur-containing oil and gas field provided by an embodiment of the present invention. Refer to attached figure 1 As shown, this embodiment provides a closed water-sealed well for sulfur-containing oil and gas fields.

[0050] The closed water-sealed well for sulfur-containing oil and gas fields in this embodiment includes: a vertical pipe 10 , a first branch pipe 1 , a second branch pipe 2 , and a flange cover 6 .

[0051] A first bypass port 102 and a second bypass port 101 are provided on the tube wall of the vertical pipe 10, and the first bypass port 102 and the second bypass port 101 are located on opposite sides of the vertical pipe 10, for example, attached figure 1As shown, the first bypass port 102 is located on the left side of the vertical pipe 10 , and the second bypass port 101 is located on the right side of the vertical pipe 10 . And the second bypass port 101 is located ...

Embodiment 2

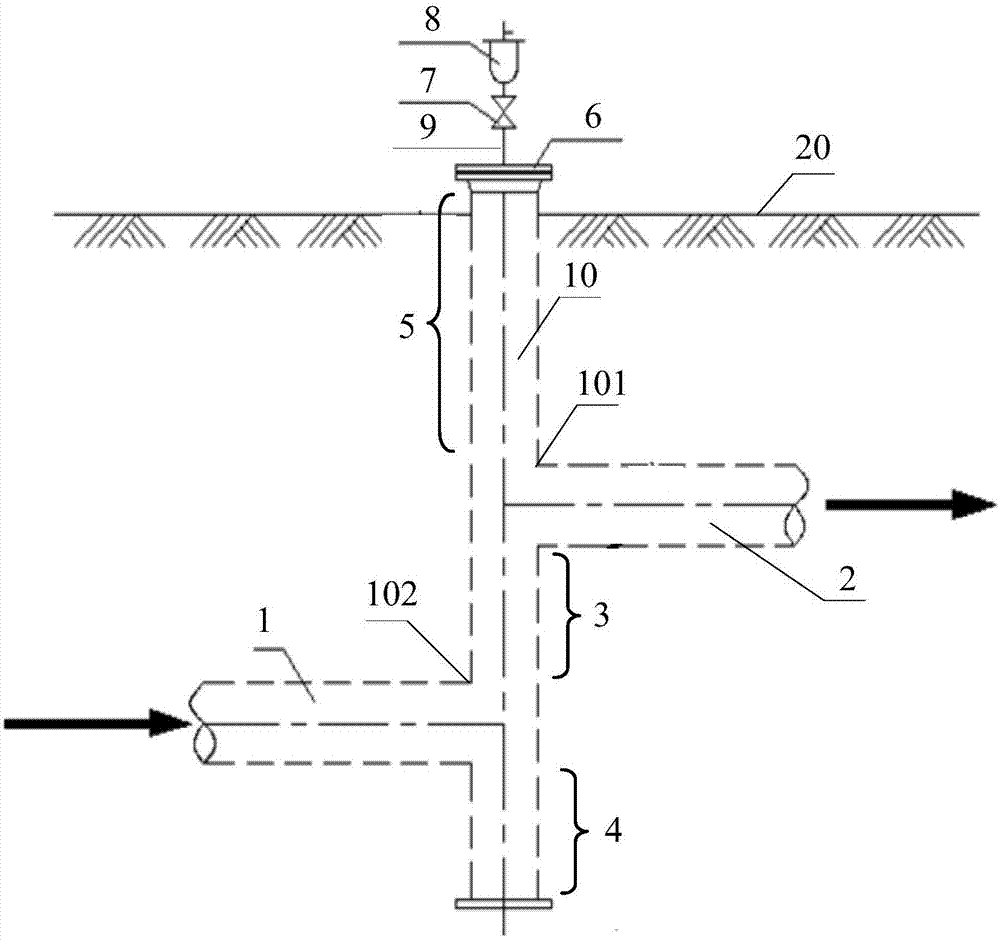

[0066] figure 2 A schematic structural diagram of a closed water-sealed well used in a sulfur-containing oil and gas field provided by another embodiment of the present invention. Refer to attached figure 2 As shown, this embodiment provides another structure for closed water-sealed wells in sour oil and gas fields.

[0067] The difference between the closed water-sealed well for sulfur-containing oil and gas fields of this embodiment and the closed-type water-sealed well for sulfur-containing oil and gas fields provided in Example 1 is that: the flange cover 6 of the water-sealed well of this embodiment is also An exhaust pipe 9 is provided, and the exhaust pipe 9 communicates with the vertical pipe 10 . The exhaust pipe 9 is also provided with a control valve for controlling the air pressure in the vertical pipe 10 .

[0068] Specifically, the control valve includes: a cut-off valve 7 and a breathing valve 8 . The shut-off valve 7 is located above the flange 6, and the ...

Embodiment 3

[0076] This embodiment provides a drainage system for sulfur-containing oil and gas fields. The drainage system includes: a drainage pipe network and a closed water-sealed well, wherein the closed water-sealed well is connected to the drainage pipe network.

[0077] The closed water-sealed well in this embodiment has the same structure as the closed water-sealed well used in the above-mentioned embodiment 1 or embodiment 2 for sulfur-containing oil and gas fields, and will not be described here one by one. For details, please refer to embodiment 1 Or the description of embodiment two.

[0078]In the drainage system provided in this embodiment, by connecting the water seal well in the drainage pipe network, since the second bypass port connected to the water outlet pipe in the water seal well is located above the first bypass port connected to the water inlet pipe, and vertically The pipe section of the pipe between the first bypass port and the second bypass port is formed as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com