Mulch picker

A technology of picking machine and mulching film, applied in the field of agricultural machinery, can solve the problems of narrow adaptation range, complex structure, unstable film yielding rate, etc., and achieve the effect of improving the unit yield level, protecting the ecological environment, and increasing the income of farmers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

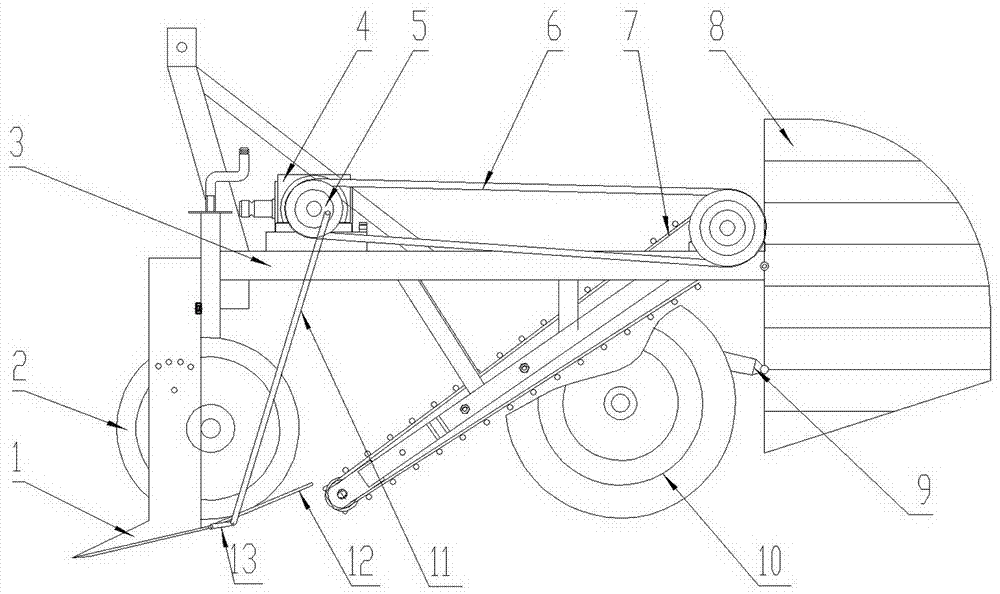

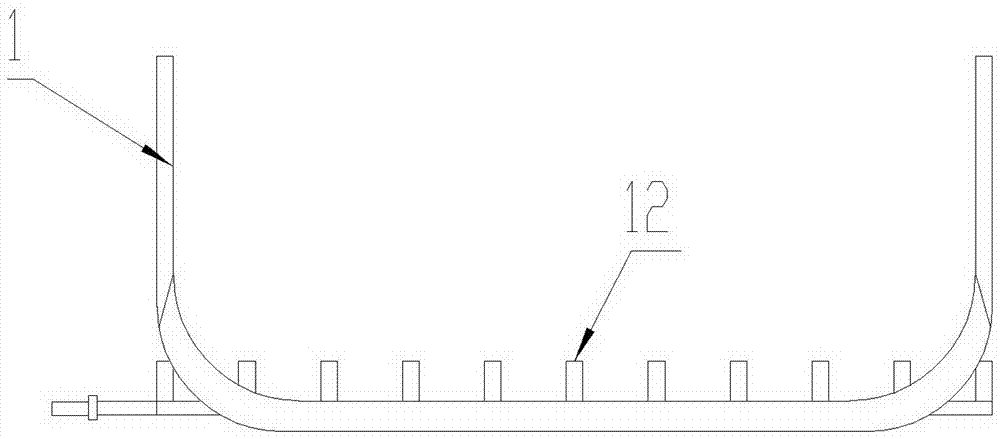

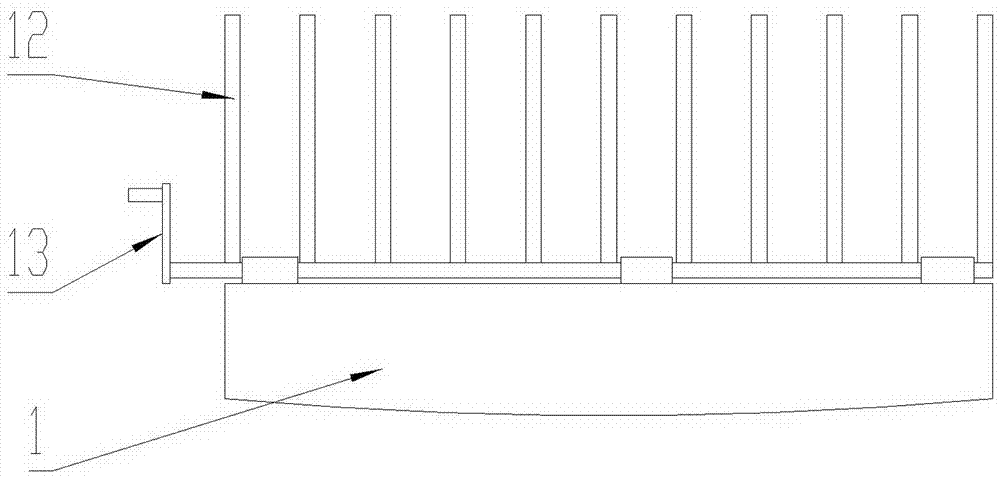

[0040] The general design of the present invention is: adopt U-shaped soil lifting shovel 1 to lift soil, shake soil fence 12 to shake soil, lift chain 7 to carry soil and shake soil twice, make residual film and soil completely separate, pack into bundles, Complete the picking and recycling of residual film. Introduce two kinds of embodiments below in conjunction with accompanying drawing.

[0041] The first embodiment: as figure 1 As shown, a mulch picking machine is provided with a U-shaped soil lifting shovel 1 at the front and lower part of the frame 3. The two sides of the U-shaped soil lifting shovel 1 are vertical knives, and the middle is a horizontal knife. Arc transition, the angle between the upper surface of the horizontal blade and the horizontal plane is the soil raising angle, and the soil raising angle is adjustable; U-shaped soil lifting shovel 1 is equipped with depth-limiting wheels 2 on both sides, and travel wheels 10 are arranged behind depth-limiting w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com