Workpiece hammering reinforcing device during metal additive manufacturing and application method thereof

A technology for strengthening devices and metal additive materials, applied in the field of additive manufacturing, can solve the problems affecting the internal quality and mechanical properties of the formed workpiece, affecting the surface accuracy and mechanical properties of the forming workpiece, and the surface flatness of the forming layer is not good. Recovery of recrystallization, suppression of crack initiation and enhancement of plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

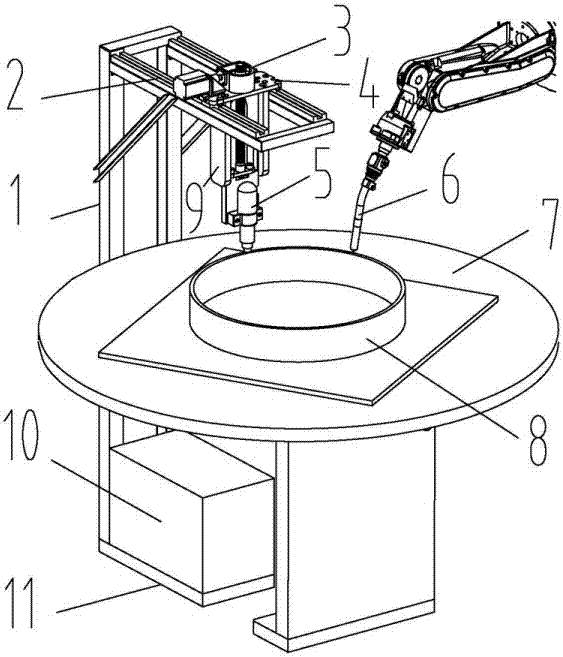

[0029] like figure 1 As shown in the present invention, in a hammer strengthening device for workpieces in the metal additive manufacturing process and its use method, the device includes a hammer strengthening device body 1, a linear motion part 2, a motion adjustment part 3, and a locking part 4 , a hammering execution part 5, a hammering adjustment bracket 9, a data processing and measurement control unit 10, a base 11; it is characterized in that: the linear motion part 2 is fixedly connected with the hammering strengthening device body 1; the movement The adjustment part 3 is fixedly connected with the hammer adjustment bracket 9, wherein the motion adjustment part 3 includes at least one set of linear transmission mechanism and can drive the hammer execution part 5 to generate displacement in the vertical direction; the hammer execution part The impact head of 5 reciprocates and contacts with the workpiece 8 in the additive manufacturing process to realize the hammering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com