Fender for waste rubber powder car and preparation method of fender

A technology for waste rubber powder and fenders, applied in chemical instruments and methods, vehicle parts, rubber layered products, etc., can solve the problem of less than 40% recycling rate, avoid resource waste and environmental pollution, avoid desulfurization , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

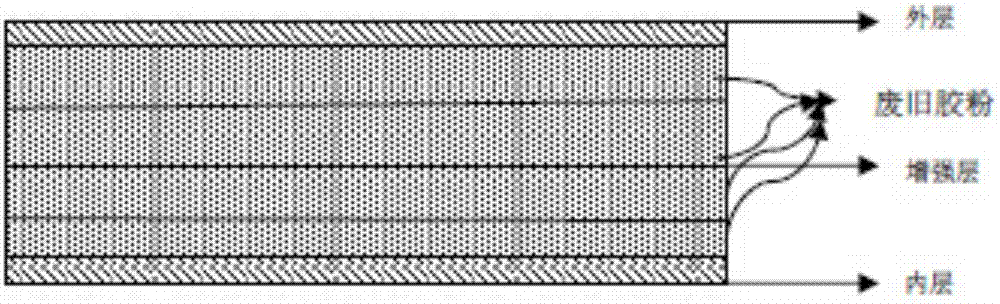

[0029] A fender for a waste rubber powder vehicle includes three layers: an inner layer, a middle layer, and an outer layer,

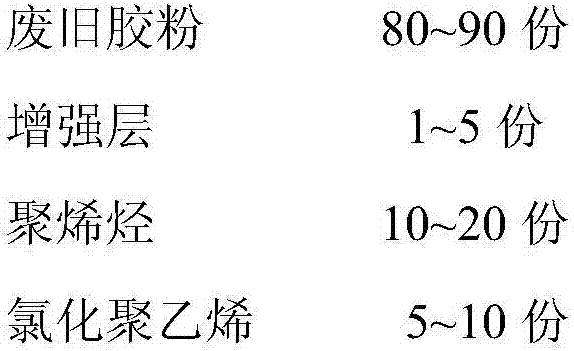

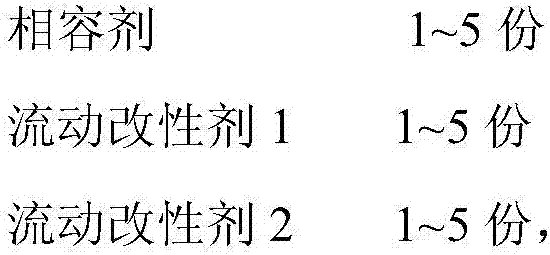

[0030] Wherein, each component of the middle layer is calculated as

[0031]

[0032] The outer and inner layers are EVA film;

[0033] According to the above formula, waste rubber powder, polyethylene, chlorinated polyethylene 6000, compatibilizer St-200, monoglyceride stearate, and FY-R10 are blended and extruded (extrusion temperature is 170-180°C) , granulation and drying, then melt the obtained particles, embed them in glass cloth until the molten resin is formed, and then obtain the middle layer of the vehicle fender; the outer layer and the inner layer are combined with the middle layer by hot post pressing .

Embodiment 2

[0035] A fender for a waste rubber powder vehicle includes three layers: an inner layer, a middle layer, and an outer layer,

[0036] Wherein, each component of the middle layer is calculated as

[0037]

[0038]

[0039] The outer and inner layers are EPDM film;

[0040] According to the above formula, waste rubber powder, poly-1-butene, chlorinated polyethylene 7000, compatibilizer St-2000, glyceryl tristearate and FY-F4500 are blended and extruded (extrusion temperature is 170~ 180°C), granulate and dry, then melt the obtained particles and embed them in the reinforcement layer 7630 until the melted resin is formed to obtain the middle layer of the vehicle fender; the outer layer and the inner layer are hot-pressed with The middle layer is combined.

Embodiment 3

[0042] A fender for a waste rubber powder vehicle includes three layers: an inner layer, a middle layer, and an outer layer,

[0043] Wherein, each component of the middle layer is calculated as

[0044]

[0045] The outer and inner layers are EPDM film;

[0046] According to the above formula, waste rubber powder, polypropylene 1600E, chlorinated polyethylene 3611E, compatibilizer FH118, ethylene bisoleic acid amide, FY--K5083E are blended and extruded (extrusion temperature is 170-180°C) , granulation and drying, and then melt the obtained particles, embed them in asbestos felt 1500, until the molten resin is formed, and then obtain the middle layer of the vehicle fender; combined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com