As-cast strong and tough ti3al intermetallic compound and its manufacturing method and application

An intermetallic compound, strong and tough technology, applied in the field of Ti-Al intermetallic compounds, can solve the problems of high density, can not meet the requirements of high thrust-to-weight ratio engine weight reduction, etc., and achieve the effect of good high temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1 # ~4 #

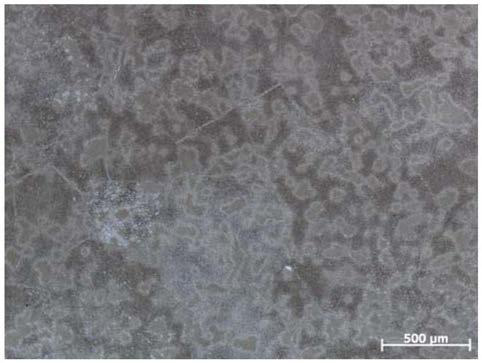

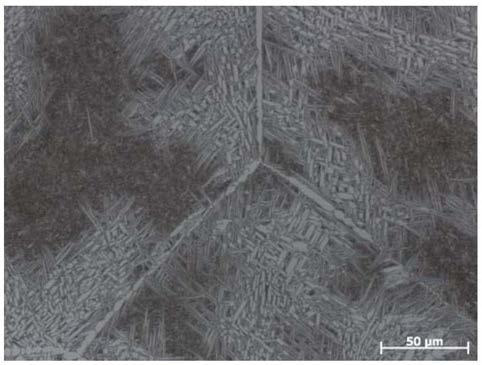

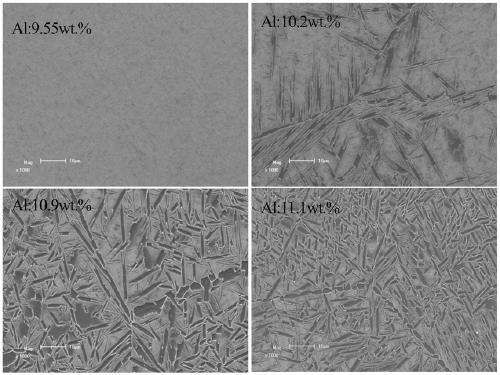

[0046] Example 1 # ~4 # The ingredients are listed in Table 2. The smelting process of the ingot is a vacuum consumable smelting, a vacuum shell smelting, a vacuum suspension smelting, and then casting into a φ70mm casting rod in a steel mold. After the cast rod is solution heat treated, the sample is processed and the mechanical properties are tested. The heat treatment system adopted is: solid solution temperature 1020°C, solid solution time 1h, cooling rate 0.5°C / s. The microstructure of the sample under the scanning electron microscope can be seen image 3 , and the tensile results at room temperature are shown in Table 3.

[0047] Table 2: Example 1 # ~4 # alloy composition

[0048] Example

Alloy Nominal Composition (at.%)

Measured Al content (wt.%)

Measured O content (wt.%)

1 #

Ti-18.5Al-15Nb-1Mo

9.55

0.068

2 #

Ti-19.5Al-15Nb-1Mo

10.2

0.069

3 #

Ti-20.5Al-15Nb-1Mo

...

Embodiment 5

[0053] Example 5 # ~6 #

[0054] Example 5 # The nominal composition is Ti-22Al-15Nb-0.5Mo (at.%), Example 6 # The nominal composition of Ti-22Al-15Nb-1Mo (at.%). The smelting process of the ingot is two vacuum consumable smelting, one vacuum suspension smelting, and then casting into a φ70mm casting rod in a steel mold. The cast rod is first processed by hot isostatic pressing (HIP): the hot isostatic pressing pressure is 130MPa, the temperature is 1020±20°C, the time is 3 hours, and it is cooled to below 300°C with the furnace. After hot isostatic pressing, the samples were subjected to different solution heat treatments and the mechanical properties were tested. The tests are shown in Tables 4 and 5.

[0055] Table 4: Example 5 # ~6 # Room temperature tensile properties

[0056]

[0057] Table 5: Example 5 # ~6 # Tensile properties at 600°C

[0058]

[0059] From the tensile properties in Tables 4 and 5, it can be seen that when the Mo content changes from ...

Embodiment 7

[0060] Example 7 # ~10 #

[0061] Example 7 # ~10 # The measured components are listed in Table 6. In the alloy ingredients, the gradient increasing O element is based on TiO 2 The preparation process of other alloys remains unchanged. The smelting process of the ingot is a vacuum self-consumption melting, a vacuum shell melting, a vacuum suspension melting, and then casting into a φ70mm casting rod in a steel mold. After the cast rod is solution heat treated, the sample is processed and the mechanical properties are tested. The heat treatment system adopted is: solid solution temperature 1020°C, solid solution time 1h, cooling rate 0.5°C / s. The tensile results at room temperature are shown in Table 7.

[0062] Table 6: Example 7 # ~10 # alloy composition

[0063] Example

[0064] Table 7: Example 7 # ~10 # Room temperature tensile properties

[0065] Example

[0066] It can be seen from Table 7 that when the O content is between 0.068 and 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com