Piston valve and using and sealing method thereof

A technology for piston valves and pistons, which is applied to multi-way valves, valve devices, engine components, etc., can solve the problems of unguaranteed sealing, complex valve structure, large pressure loss, etc., and achieve long anti-cavitation time and good sealing effect , The effect of small opening force of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

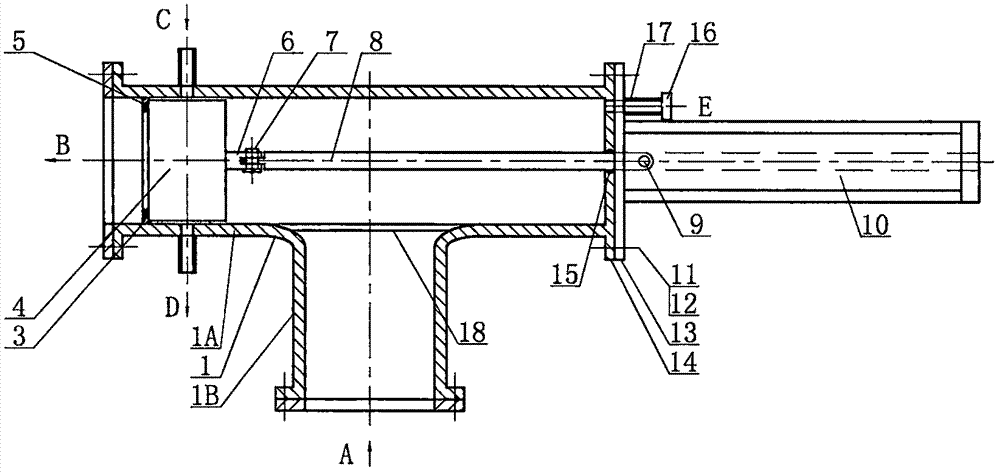

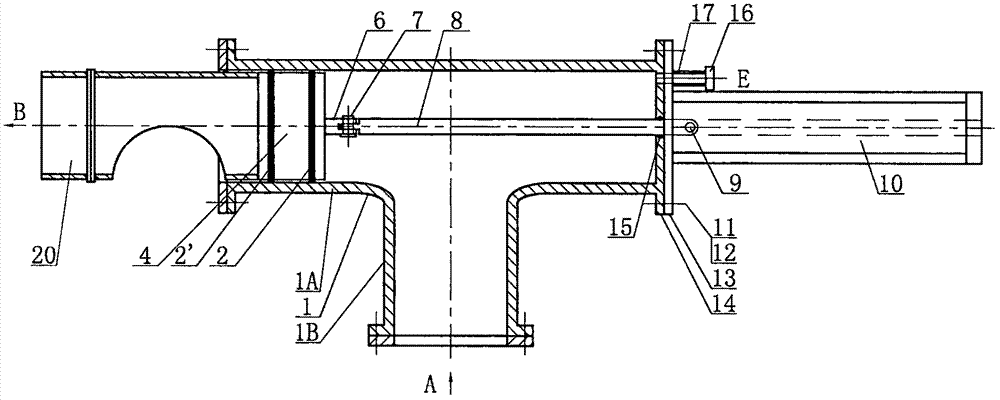

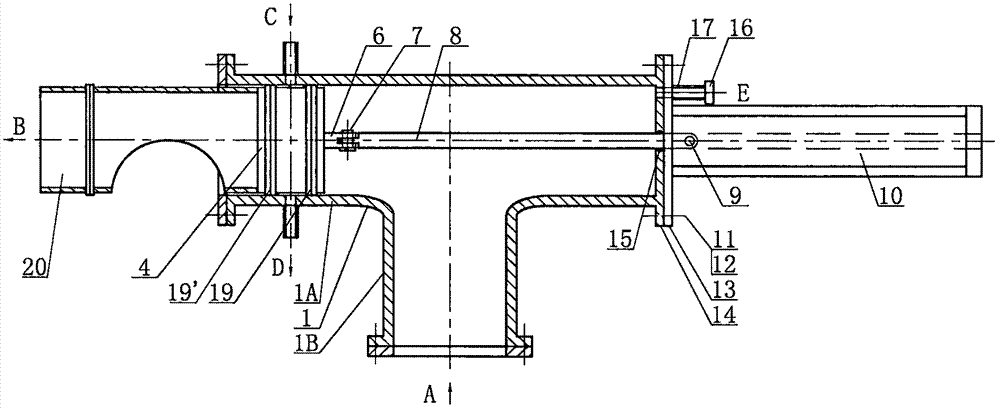

[0087] A piston valve such as figure 1 As shown, it includes a three-way valve body 1, a piston 4, a pull rod 8, a flange cover 14 and a drive mechanism 10; The pull ear 6 is hinged, and the other end is hinged with the drive mechanism 10 through the pin shaft 9; one side of the flange cover 14 is welded to one end of the straight-through pipe 1A of the valve body, and the other side is connected to the base of the drive mechanism 10 through bolts 11 Connect with the nut 12; the flange cover 14 has a hole with the same size as the pull rod 8, and the two are slidingly fitted, and the pull rod 8 always extends out of the flange cover 13. There is an annular groove on the inner surface of the hole on the flange cover, and a seal 15 is housed in the annular groove, such as a sealing ring or a sealing packing, etc.; the valve of this structure is used in occasions where sealing requirements are not strict. The medium enters through the inlet A of the valve body and flows out thro...

Embodiment 2

[0089] On the basis of Example 1, in order to further improve the sealing effect, as figure 1 As shown, the inner surface of the straight-through pipe 1A of the three-way valve body 1 is fixed with an annular valve seat 3 coaxial with the straight-through pipe 1A; the annular valve seat 3 forms a sealing surface with the axial section of the piston.

Embodiment 3

[0091] On the basis of Example 2, in order to further improve the sealing effect, an annular groove is processed on the surface of the annular valve seat 3 facing the piston 4, and a ring of elastic sealing packing or a metal hollow O-shaped groove is fixed in the groove. Ring 5, sealing packing or metal hollow O-ring 5 protrude from the surface of annular valve seat 3, such as figure 1 shown. Wherein, the elastic sealing packing is silica gel or fluororubber;

[0092] In order to prevent the deposition of impurities on the sealing surface from affecting the sealing, the outlet and inlet of the three-way valve body can be reversed and used

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com