Flotation technology of coal gasification fine slag

A technology of coal gasification and fine slag, applied in flotation, solid separation and other directions, can solve the problems of pollution, waste of energy, consumption of large cultivated land and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

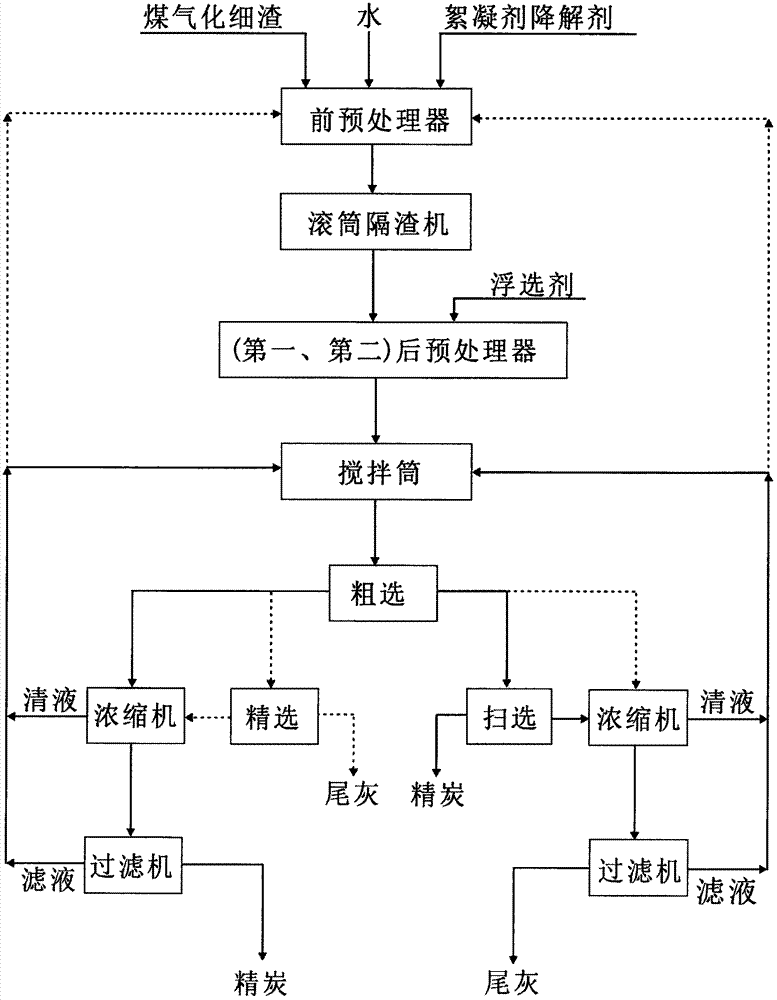

[0025] Combine below figure 1 Describe its specific implementation, a kind of flotation process of coal gasification fine slag, comprises the following steps:

[0026] 1. Coal gasification fine slag enters the pre-processor through belt conveyor or bucket elevator, add 0.05% potassium persulfate, add 0.01% ferrous sulfate heptahydrate, and add water to make the slurry concentration of coal gasification fine slag 20 %, adjust the pH value between 2-11, and the residence time is 15 minutes.

[0027] 2. Remove particles larger than 0.5 through the drum slag separator (rotary sieve).

[0028] 3. Enter the first after-preprocessor, add the diesel oil of 0.5% (diesel oil / slurry weight percent); Then enter the second post-processor and add 0.5% (secondary octanol / slurry weight percent) secondary octanol .

[0029] 4. Coal gasification fine slag slurry and reused filtrate enter the mixing tank at the same time to reduce the concentration of the slurry to 10%. After stirring evenly,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com