A method for comprehensive utilization of low-grade magnesite and boronite

A magnesite, low-grade technology, applied in the direction of boron compounds, boron oxide compounds, chemical instruments and methods, etc., can solve the problems of mine vegetation restoration and low comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

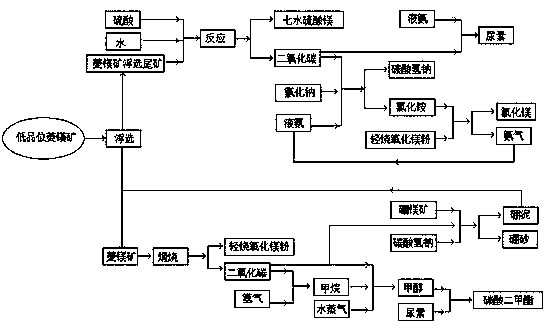

[0053] (1) Weigh 100g of low-grade magnesite flotation tailings powder, pour it into a 500ml beaker together with 300ml of deionized water, stir well, pour it into a 500ml three-necked flask, and measure the concentrated sulfuric acid with a graduated cylinder Take 100 ml, dilute to 50% (mass ratio), start stirring at 300 rpm, heat up to 85°C-120°C, and react for 2-5 hours.

[0054] (2) Carbon dioxide is passed into an aqueous solution containing 60 grams of sodium chloride and 30 milliliters of ammonia water, and the absorption reaction generates sodium bicarbonate and ammonium chloride.

[0055] (3) Carbon dioxide and liquid ammonia use industrial urea production technology to produce urea.

[0056] (4) Weigh 1,000 grams of magnesite powder after flotation of low-grade magnesite, mix it with 100 grams of boron mud (magnesium basic carbonate), heat up to 750°C, and calcinate for 2 hours to recover carbon dioxide.

[0057] (5) Part of the carbon dioxide collected by calcinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com