Concrete and cracking-resistant pouring method by adopting concrete

A concrete and anti-cracking technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of concrete continuity decrease, concrete strength decrease, concrete layer slip, etc., to avoid excessive temperature difference, Improve compactness and improve the effect of porosity structural steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] A kind of concrete, according to the amount of concrete per cubic meter, includes the following components: 270kg of cement, 134kg of water, 528kg of fine aggregate, 1200kg of coarse aggregate, 3.5kg of pumping agent, 27kg of expansion agent and 10kg of fly ash. The agent is AEA expansion agent.

[0025] Adopt the concrete pouring pile raft foundation in this specific embodiment, this foundation is cuboid structure, length 19.7m, width 15.5m, height 2.4m, ambient average temperature is 23 ℃, relatively cool, according to the anti-cracking pouring method of the present invention, Include the following steps:

[0026] Step 1: Add ice cubes to stir the concrete, the amount of ice cubes added is 44kg / m3;

[0027] Step 2: Pump the well-mixed concrete into the mold cavity continuously, and vibrate evenly until the entire mold cavity is poured and rammed.

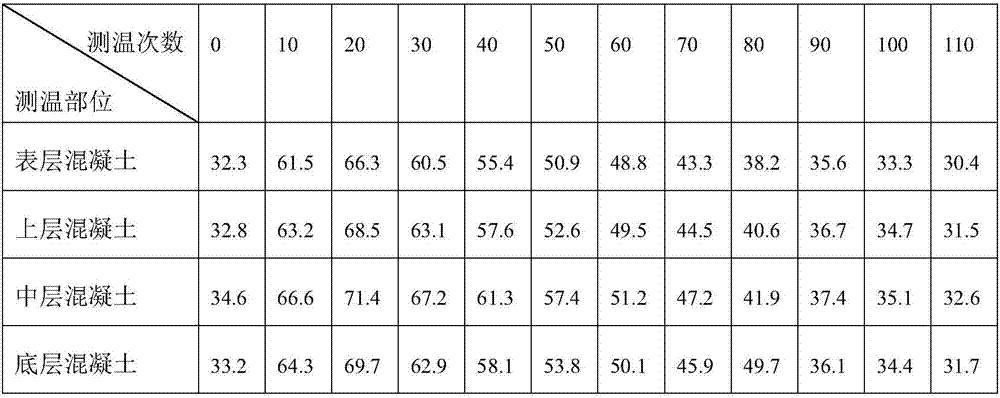

[0028] In this specific embodiment, when the concrete pouring height reaches 1 / 3 of the mold cavity height, the bottom ...

specific Embodiment approach 2

[0038] A kind of concrete, according to the amount of concrete per cubic meter, includes the following components: 286kg of cement, 141kg of water, 548kg of fine aggregate, 1260kg of coarse aggregate, 4.2kg of pumping agent, 29kg of expansion agent, and 105kg of fly ash.

[0039]The concrete pouring pile raft foundation in this specific embodiment is used. The foundation is a cuboid structure with a length of 26.7m, a width of 20.8m, and a height of 4.2m. The average temperature of the environment is 35°C, and the weather is relatively hot. Fly ash, fine aggregate and coarse aggregate carry out water spraying, by anti-cracking pouring method of the present invention, comprise the following steps:

[0040] Step 1: Add ice cubes to stir the concrete, the amount of ice cubes added is 47kg / m 3 ;

[0041] Step 2: Pump the well-mixed concrete into the mold cavity continuously, and vibrate evenly until the entire mold cavity is poured and rammed.

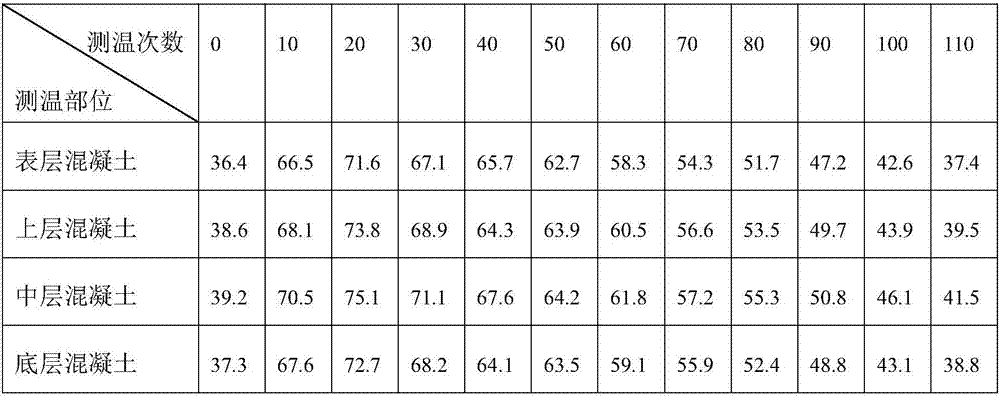

[0042] In this specific embodimen...

specific Embodiment approach 3

[0052] A kind of concrete, according to the amount of concrete per cubic meter, includes the following components: 290kg of cement, 164kg of water, 560kg of fine aggregate, 1350kg of coarse aggregate, 5.6kg of pumping agent, 32kg of expansion agent and 116kg of fly ash.

[0053] Adopt the concrete pouring pile raft foundation in this specific embodiment, this foundation is cuboid structure, length 30.7m, width 20.8m, height 5.6m, ambient average air temperature is 12 ℃, and temperature is lower, according to the anti-cracking pouring method of the present invention , including the following steps:

[0054] Step 1: Add ice cubes to stir the concrete, the amount of ice cubes added is 41kg / m 3 ;

[0055] Step 2: Pump the well-mixed concrete into the mold cavity continuously, and vibrate evenly until the entire mold cavity is poured and rammed;

[0056] Step 3: Cover the upper surface of the concrete with an insulating layer after pouring and tamping; the insulating layer includ...

PUM

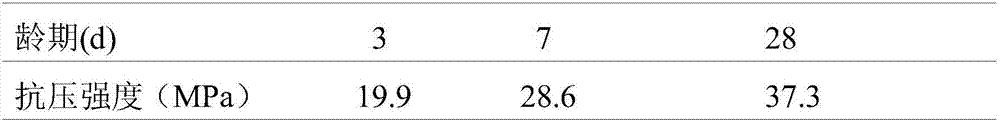

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com