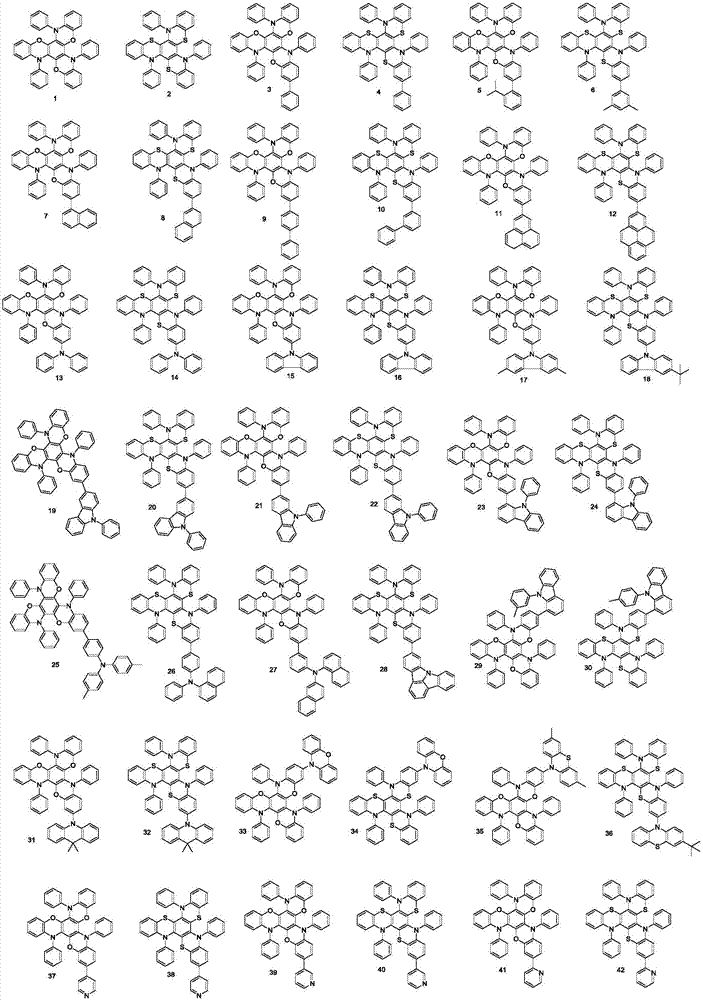

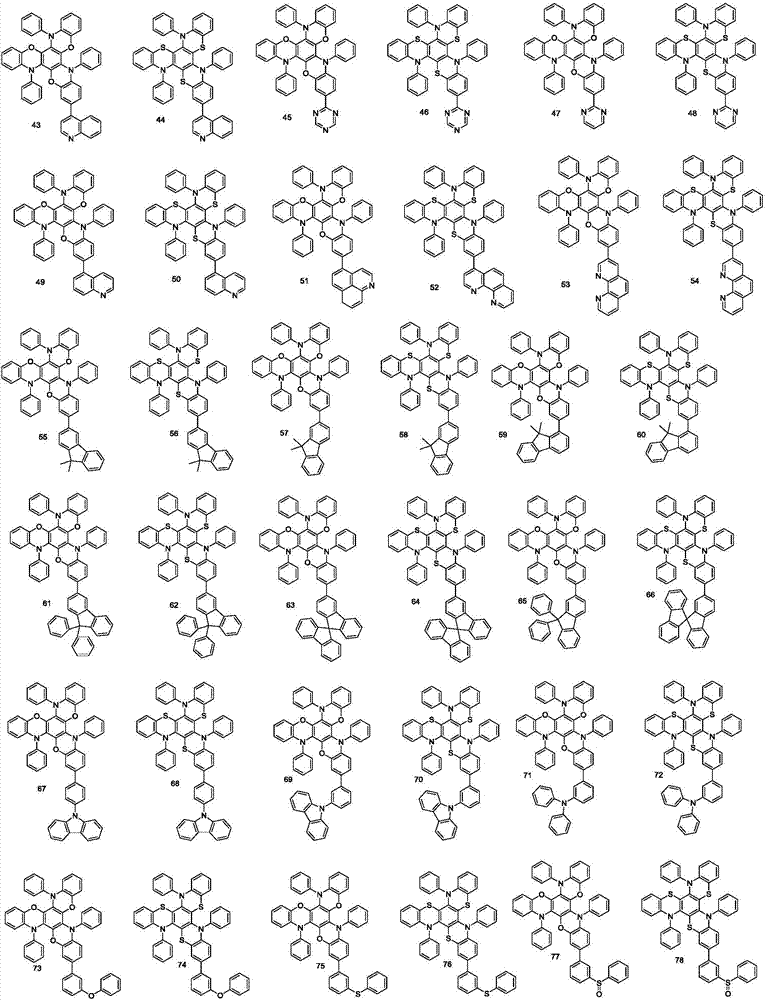

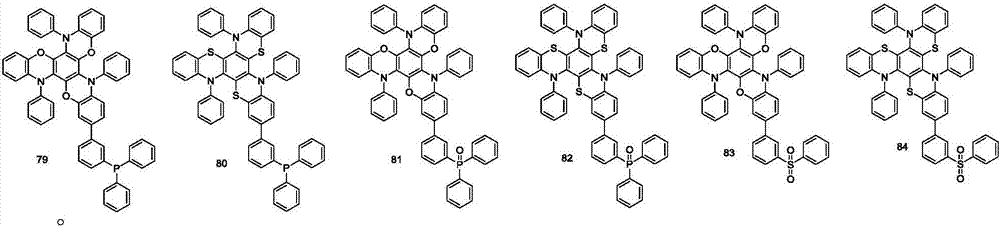

Organic electroluminescence material with phenoxazine/thenoxazin type derivative and organic luminescent device

An electroluminescent material and phenoxazine technology, which is applied in the manufacturing of luminescent materials, electro-solid devices, semiconductor/solid-state devices, etc., can solve the problems of reduced luminous efficiency and inability to improve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: 1 synthesis of compound

[0042]

[0043] Step1. Dissolve 100 mmol of phloroglucinol and 100 mmol of o-fluoronitrobenzene in DMF, add 3 equivalents of potassium tert-butoxide, and 0.05 equivalents of phase transfer catalyst at 100°C for 6 hours. After the reaction was completed, the reaction solution was poured into water, filtered to obtain a filter cake, and the crude product was passed through a silica gel column to obtain 84 mmol of product 1-1.

[0044]Step2. Add 84 mmol of compound 1-1, solvent o-dichlorobenzene, 5 equivalents of triethyl sulfite, replace argon three times, raise the temperature to 165°C for 12 hours, and the reaction takes about 15 hours. The reaction solution was cooled to room temperature, and dichloromethane was added under stirring to dissolve all the product. The organic phase was washed with deionized water, distilled under pressure at 150 degrees Celsius, and concentrated to dryness to obtain a yellow oily viscous liquid. ...

Embodiment 2

[0046] Embodiment 2: 2 synthesis of compound

[0047] The synthetic method is the same as in Example 1, and the phloroglucinol in Step1. is replaced with phloroglucinol.

Embodiment 3

[0048] Embodiment 3: 3 synthesis of compound

[0049]

[0050] Step1. Dissolve 100 mmol of phloroglucinol and 100 mmol of o-fluoronitrobenzene in DMF, add 3 equivalents of potassium tert-butoxide, and 0.05 equivalents of phase transfer catalyst at 100°C for 6 hours. After the reaction was completed, the reaction solution was poured into water, filtered to obtain a filter cake, and the crude product was passed through a silica gel column to obtain 84 mmol of product 1-1.

[0051] Step2. Add 84 mmol of compound 1-1, solvent o-dichlorobenzene, 5 equivalents of triethyl sulfite, replace argon three times, raise the temperature to 165°C for 12 hours, and the reaction takes about 15 hours. The reaction solution was cooled to room temperature, and dichloromethane was added under stirring to dissolve all the product. The organic phase was washed with deionized water, distilled under pressure at 150 degrees Celsius, and concentrated to dryness to obtain a yellow oily viscous liquid....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com