Environmental-friendly concentrated natural soap powder and preparation process thereof

A natural soap powder, a technology for preparation process, applied in soap detergent compositions, surface-active non-soap compounds and cleaning compositions, chemical instruments and methods, etc., can solve the problems of high foam, not easy to rinse, etc., and achieve laundry foam. Less, easy rinsing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

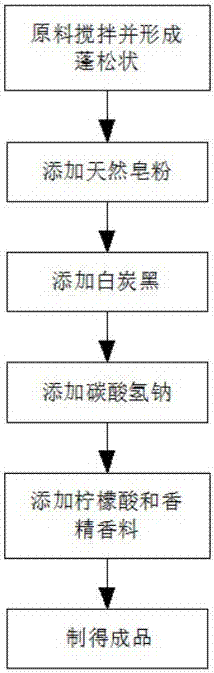

Image

Examples

Embodiment 1

[0023] A kind of environmental protection concentrated type natural soap powder, this environmental protection concentrated type natural soap powder is made up of the raw material of following mass parts:

[0024] Sodium carbonate: 20 parts;

[0025] Fatty alcohol polyoxyethylene ether: 5 parts;

[0026] White carbon black: 1 part;

[0027] Natural soap powder: 8 parts;

[0028] Citric acid: 3 parts;

[0029] Sodium bicarbonate: 50 parts;

[0030] Flavors and fragrances: 0.1 parts.

[0031] The present invention also provides a kind of environmental protection concentrated type natural soap powder preparation process, the concrete steps of this environmental protection concentrated type natural soap powder preparation process are as follows:

[0032] S1: Put 20 parts of sodium carbonate into the spiral stirring device for rapid stirring for 1 minute and 08 seconds, spray 5 parts of pre-heated fatty alcohol polyoxyethylene ether with an automatic constant temperature spray...

Embodiment 2

[0038] A kind of environmental protection concentrated type natural soap powder, this environmental protection concentrated type natural soap powder is made up of the raw material of following mass parts:

[0039] Sodium carbonate: 25 parts;

[0040] Fatty alcohol polyoxyethylene ether: 10 parts;

[0041] White carbon black: 3 parts;

[0042] Natural soap powder: 12 parts;

[0043] Citric acid: 5 parts;

[0044] Sodium bicarbonate: 58 parts;

[0045] Flavors and fragrances: 0.3 parts.

[0046] The present invention also provides a kind of environmental protection concentrated type natural soap powder preparation process, the concrete steps of this environmental protection concentrated type natural soap powder preparation process are as follows:

[0047] S1: Put 25 parts of sodium carbonate into a spiral stirring device for rapid stirring for 1 minute and 08 seconds, spray 10 parts of fatty alcohol polyoxyethylene ether that has been heated in advance with an automatic con...

Embodiment 3

[0053] A kind of environmental protection concentrated type natural soap powder, this environmental protection concentrated type natural soap powder is made up of the raw material of following mass parts:

[0054] Sodium carbonate: 23 parts;

[0055] Fatty alcohol polyoxyethylene ether: 8 parts;

[0056] White carbon black: 2 parts;

[0057] Natural soap powder: 10 parts;

[0058] Citric acid: 4 parts;

[0059] Sodium bicarbonate: 54 parts;

[0060] Flavors and fragrances: 0.2 parts.

[0061] The present invention also provides a kind of environmental protection concentrated type natural soap powder preparation process, the concrete steps of this environmental protection concentrated type natural soap powder preparation process are as follows:

[0062] S1: Put 28 parts of sodium carbonate into a spiral stirring device for rapid stirring for 1 minute and 08 seconds, spray 8 parts of fatty alcohol polyoxyethylene ether that has been heated in advance with an automatic const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com