A kind of food processing machine rotary valve control method

A food processing machine and control method technology, applied in kitchen utensils, home utensils, applications, etc., can solve the problems of inability to ensure safe and reliable switching of pipelines, single control method, and reduce the service life of pipelines, etc., to achieve automatic identification and Troubleshooting, solution control method is single, and the effect of ensuring safe and reliable switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

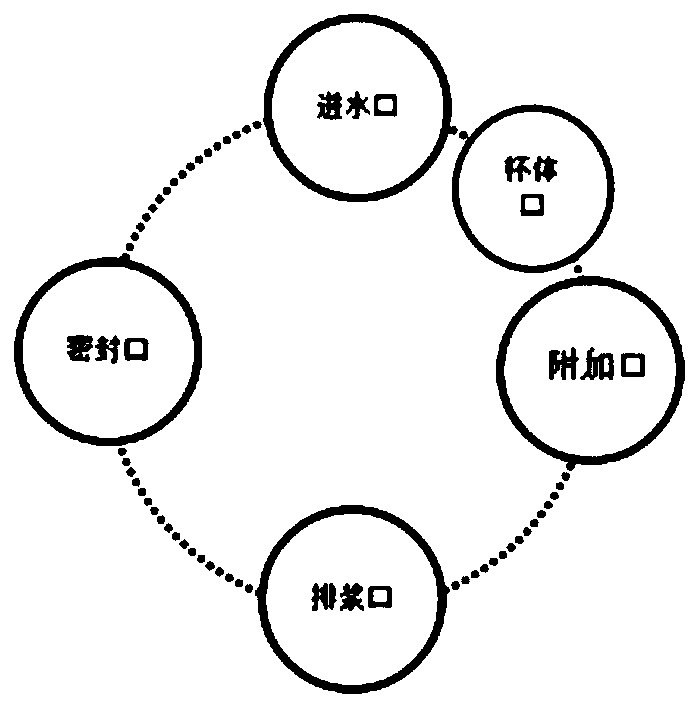

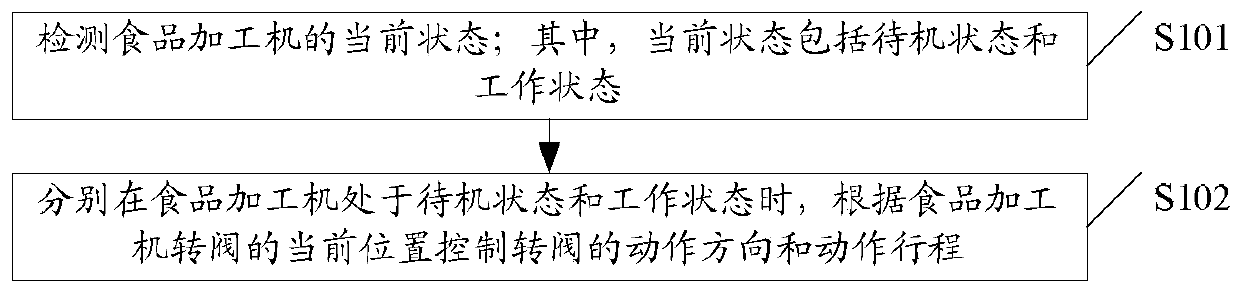

[0048] A method for controlling a rotary valve of a food processing machine, such as figure 1 As shown, the rotary valve of the food processor includes: an up rotary valve and a down rotary valve. Switching between pulp mouth and pulp cup and waste water box, such as figure 2 As shown, the control method includes S101-S102:

[0049] S101. Detect the current state of the food processing machine; wherein, the current state includes a standby state and a working state.

[0050] In the embodiment of the present invention, in order to automatically determine the best action path according to the different states of the food processor, and to control the rotary valve of the food processor accordingly, to ensure safe and reliable switching of the pipeline, the action time of the rotary valve is shortened, and the In the pulping cycle, the current state of the food processor can be detected first to judge the switching working environment of the rotary valve.

[0051] In the embod...

Embodiment 2

[0076] In this embodiment, on the basis of the first embodiment, the stroke of the rotary valve is further limited.

[0077] Optionally, the method further includes: changing the position of the up-rotation valve according to the shortest stroke.

[0078] In the embodiment of the present invention, when the up-rotation valve is switched, the minimum action stroke can be selected to switch the up-rotation valve.

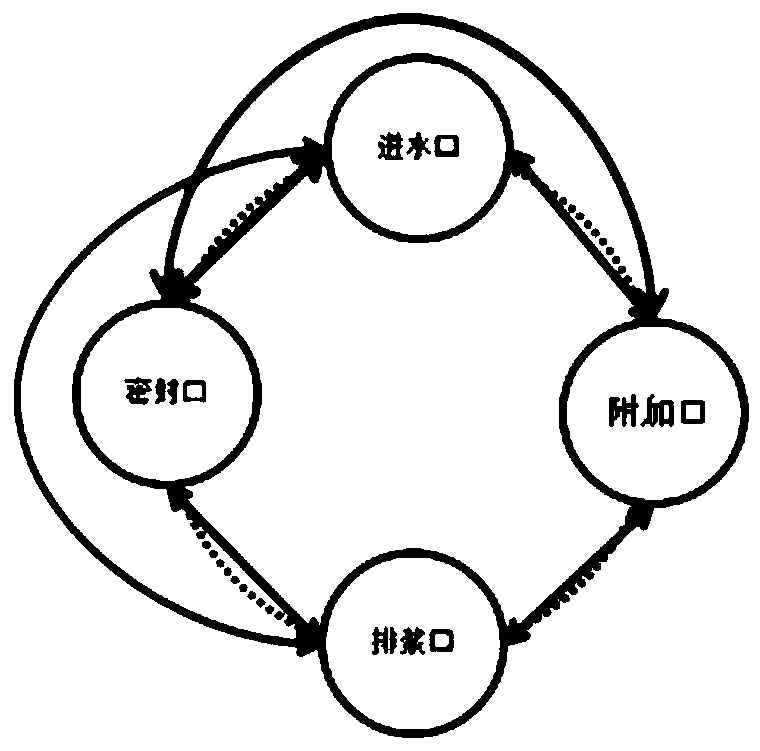

[0079] Optionally, the water inlet, sealing port, slurry discharge port and additional port are sorted counterclockwise;

[0080] like image 3 As shown, changing the position of the upturn valve according to the shortest stroke can include:

[0081] When the two ports that need to be converted are adjacent, without going through other ports, directly rotate clockwise or counterclockwise to turn the up-rotating valve to the target port position;

[0082] When the two openings that need to be converted are diagonal openings, the diagonal opening includes: the relati...

Embodiment 3

[0087]On the basis of the first embodiment, this embodiment provides a material detection embodiment scheme.

[0088] Optionally, the first water intake is the maximum pulping capacity;

[0089] Detecting whether there is material in the cup includes: based on the first water intake, detecting the motor current when the motor is working, and judging whether there is material in the cup according to the magnitude of the motor current.

[0090] In the embodiment of the present invention, the water intake of steam is the maximum capacity of pulping, which ensures that the water level in the cup is controlled at a fixed position regardless of whether it is due to the user adding water by mistake or the last round of abnormal power failure, so as to ensure a constant amount of material.

[0091] In the embodiment of the present invention, the method for judging whether there is material in the cup is determined according to the motor current value when the motor is working, because...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com