Efficient welding method of S460NL high-strength steel flange

A welding method and high-strength steel technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of slow welding speed, large spatter, and large welder damage, and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

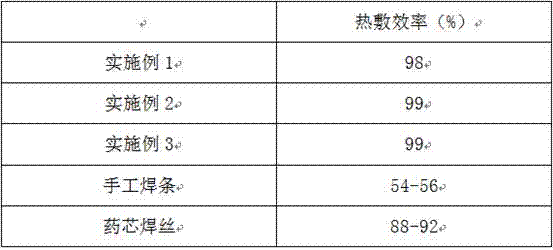

Examples

Embodiment 1

[0021] A high-efficiency welding method for S460NL high-strength steel flanges. After two steps of welding material selection and welding control process, the efficient welding method for S460NL high-strength steel flanges is completed; the specific steps are as follows:

[0022] (1) Selection of welding materials: use submerged arc welding for welding, use H-14 welding wire as the welding wire, and use fluorine-alkaline sintering flux as the sintering flux. The diameter of the welding wire is 4mm, and the alkalinity of the flux is 3.0.

[0023] (2) Welding control process:

[0024] a. Use semi-automatic flame cutting method to cut the groove of S460NL high-strength steel flange, and clean the oil, rust, oxide and other impurities within 30mm around the groove of the weld seam until the metallic luster is exposed;

[0025] b. When the S460NL high-strength steel flange is assembled, the inner wall is flush, if there is a gap, the value of the gap is 0mm;

[0026] c. The area t...

Embodiment 2

[0030] A high-efficiency welding method for S460NL high-strength steel flanges. After two steps of welding material selection and welding control process, the efficient welding method for S460NL high-strength steel flanges is completed; the specific steps are as follows:

[0031] (1) Selection of welding materials: use submerged arc welding for welding, use H-14 welding wire as the welding wire, and use fluorine-alkaline sintering flux as the sintering flux. The diameter of the welding wire is 4mm, and the alkalinity of the flux is 3.0.

[0032] (2) Welding control process:

[0033] a. Use semi-automatic flame cutting method to cut the groove of S460NL high-strength steel flange, and clean the oil, rust, oxide and other impurities within 50mm around the groove of the weld seam until the metallic luster is exposed;

[0034] b. When the S460NL high-strength steel flange is assembled, the inner wall is flush, if there is a gap, the value of the gap is 1mm;

[0035] c. The area t...

Embodiment 3

[0039] A high-efficiency welding method for S460NL high-strength steel flanges. After two steps of welding material selection and welding control process, the efficient welding method for S460NL high-strength steel flanges is completed; the specific steps are as follows:

[0040] (1) Selection of welding materials: use submerged arc welding for welding, use H-14 welding wire as the welding wire, and use fluorine-alkaline sintering flux as the sintering flux. The diameter of the welding wire is 4mm, and the alkalinity of the flux is 3.0.

[0041] (2) Welding control process:

[0042] a. Use semi-automatic flame cutting method to cut the groove of S460NL high-strength steel flange, and clean up the oil, rust, oxide and other impurities within 40mm around the groove of the weld until the metallic luster is exposed;

[0043] b. When the S460NL high-strength steel flange is assembled, the inner wall is flush, and if there is a gap, the value of the gap is 0.5mm;

[0044] c. The ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com