Flue gas analysis device based on ultraviolet difference technology, and flue gas analysis method

A technology of flue gas analysis and ultraviolet difference, which is applied in the field of flue gas analysis devices based on ultraviolet difference technology, can solve the problems of not meeting the monitoring requirements, increasing the difficulty of on-site maintenance, increasing the complexity of the system, etc., achieving strong anti-background gas interference, Improve measurement accuracy and improve the effect of spectral signal intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

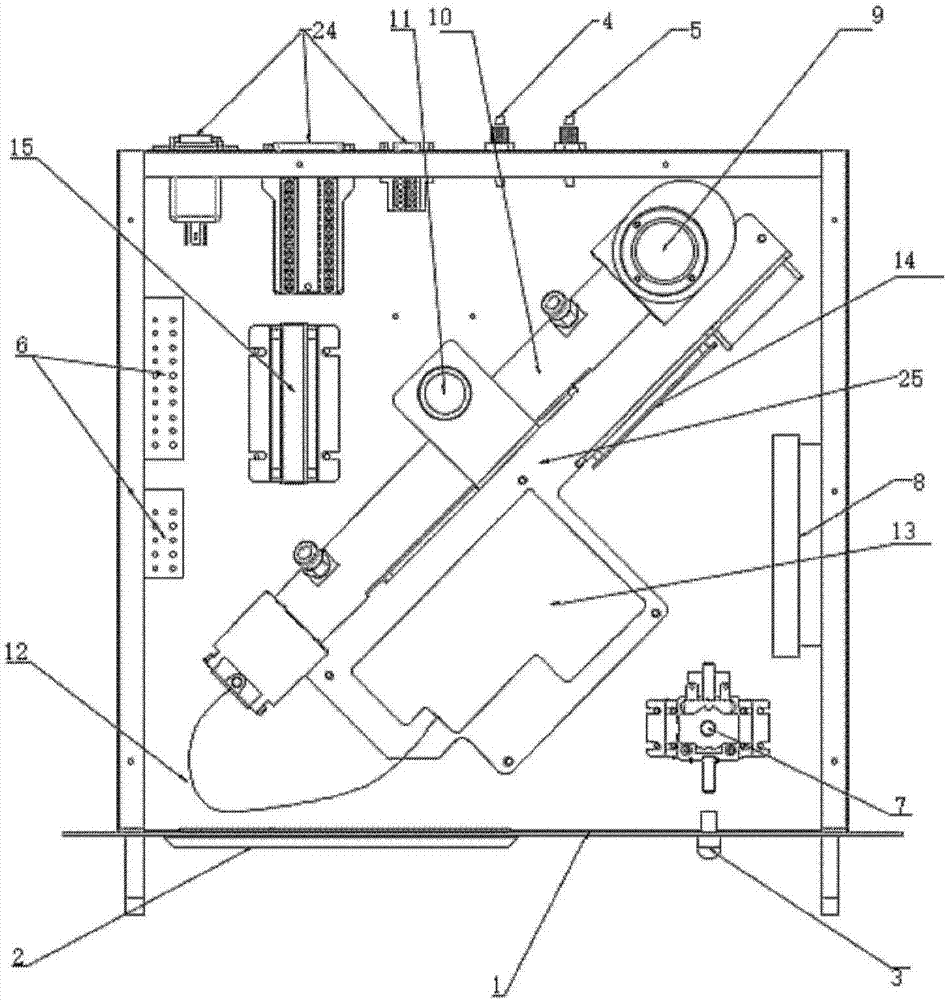

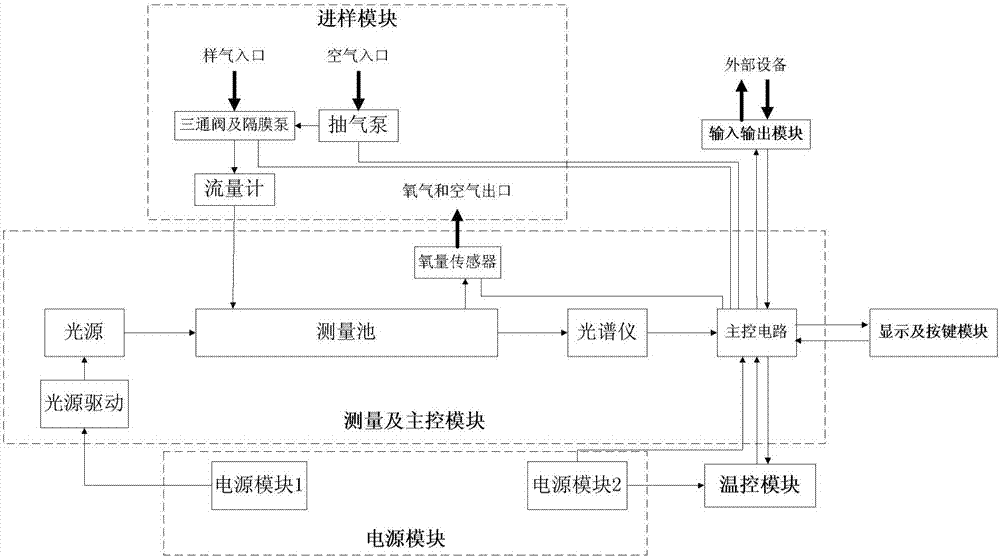

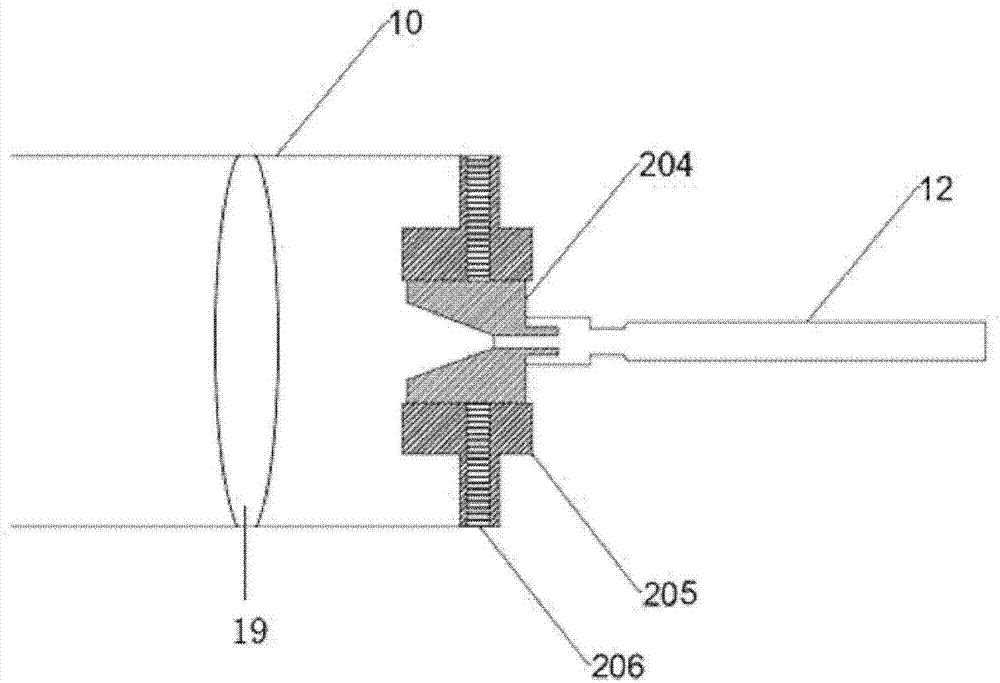

[0040] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings, the contents of which are sufficient to enable any person skilled in the art to understand the technical content of the present invention and According to implement.

[0041] When using ultraviolet differential absorption spectroscopy for detection, the light absorption of the sample gas can be divided into two parts: one part changes rapidly with the wavelength and constitutes the narrow-band fine structure of the spectrum, this part is only related to the characteristic absorption of the gas to be measured; the other part changes with the wavelength Slowly changing, constituting the broadband structure of the spectrum, this part is not only related to the characteristics of some gases, but also related to the scattering of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com