Testing system and method for interaction study of melt and liquid metals

A liquid metal, test system technology, applied in nuclear power generation, climate sustainability, cooling devices, etc., can solve extremely high operational requirements, inability to study the impact of molten liquid column melt fragmentation characteristics, and differences in reactor operating conditions great problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

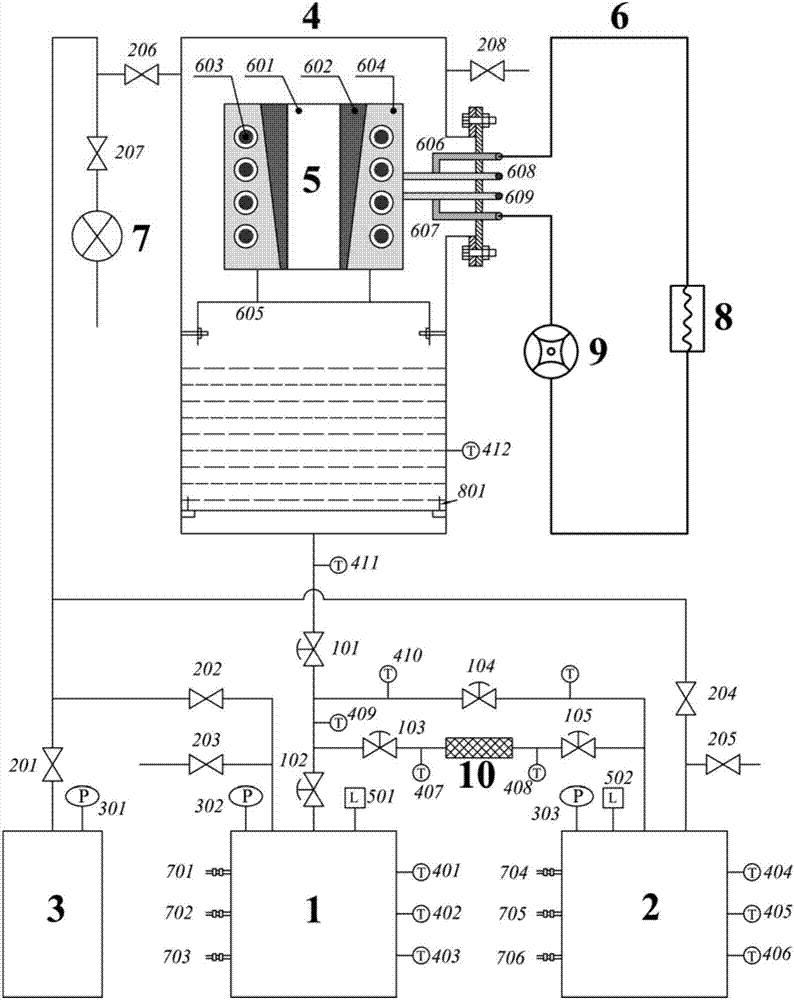

[0022] Such as figure 1As shown, the present invention is a test system and method for studying the interaction between molten matter and liquid metal. The test system includes a sodium storage tank 1, a sodium return tank 2, an argon buffer tank 3, a reaction vessel 4, and an electromagnetic induction heating furnace 5. Oil cooling circuit 6, vacuum pump 7, oil cooling compressor 8, oil pump 9, liquid metal sodium filtering device 10 and pipeline valves; the reaction vessel 4 is the main device of the test system, and the upper space is equipped with electromagnetic induction Heating the melting furnace 5 to provide molten material for the experiment by means of electromagnetic induction heating; the lower space is filled with liquid metal sodium filled from the sodium storage tank 1, and according to the requirements of the experimental working condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com