Electrolyte, positive electrode, preparation method thereof, and lithium ion battery

A technology of electrolyte and positive electrode, applied in the field of positive electrode and its preparation, electrolyte, can solve the problems of side reaction, decrease of battery cycle performance, inability to work normally, etc., to achieve the effect of prolonging life and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The invention provides a method for preparing a positive electrode, comprising:

[0057] (1) Forming a positive electrode material layer on the surface of the positive electrode current collector;

[0058] (2) The electrolytic solution described in any one of claims 1-9 is contacted with the positive electrode material layer surface, and the voltage during contact is 3.5V-4.5V.

[0059] The present invention provides a positive electrode prepared by the above method.

[0060] The preparation method of lithium-ion battery electrolyte is a common method for those skilled in the art, that is, to mix all components (including lithium salt, electrolyte solvent and additives) uniformly, and the method and order of mixing are not particularly limited in the present invention.

[0061] The present invention also provides a lithium-ion battery, comprising a casing, an electric core contained in the casing, and an electrolyte, the electric core includes a positive electrode, a n...

Embodiment 1

[0075] (1) Preparation of electrolyte:

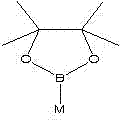

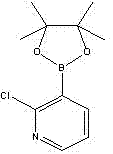

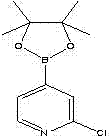

[0076] In an argon glove box, ethylene carbonate (EC), diethyl carbonate (DEC), 12% by weight lithium hexafluorophosphate (LiPF 6 ) is dissolved in the electrolytic solution solvent of 100% weight part, then adds the 4-bromomethylphenylboronic acid pinacolate of 0.1% weight part (the boric acid pinacolate of structure shown in the application formula (1), wherein M is 4 -Bromomethylbenzene obtains the lithium-ion battery electrolyte of the present embodiment, which is denoted as C1;

[0077] (2) Preparation of lithium ion battery:

[0078] The positive active material (LiNi 0.5 mn 1.5 o 4 ), acetylene black, and polyvinylidene fluoride in a ratio of 90:5:5 and then pressed on the aluminum foil to obtain the positive electrode sheet; the metal lithium sheet was used as the negative electrode sheet; the PE / PP composite diaphragm was used as the ion exchange membrane. The electrolyte C1 of the example is made into a button battery S1 ...

Embodiment 2

[0080] Adopt the step identical with embodiment 1 to prepare electrolytic solution and button cell, difference is: in the step (1), replace 4-bromomethylphenylboronic acid pinacolate with the vinylboronic acid pinacolate of 0.5% weight part, Lithium-ion battery electrolyte C2 and button battery S2 were prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com