Mechanical stubble cleaning and straw returning method

A straw and stubble removal technology, which is applied in the fields of soil preparation methods, agricultural machinery and implements, and applications, can solve the problems of affecting the growth of sowing seedlings of the next crops, affecting the growth and yield of the next crops, and the adverse effects of the growth of the next crops. Improve the ability of soil to digest straw, easy to spread, and less pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

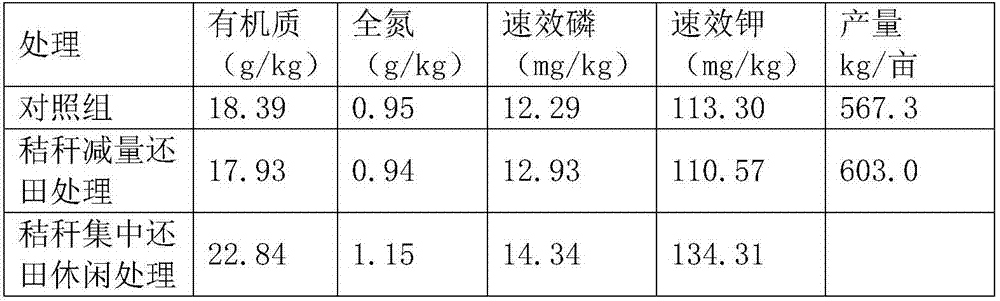

Embodiment 1

[0023] Location: Madian Experimental Station of Provincial Academy of Agricultural Sciences, Mengcheng County, Anhui Province. Soil for test: Shajiang black soil. Rotation of wheat and corn.

[0024] Control group (full amount of straw directly returned to the field): After the wheat crops were harvested, the stubble machine was used to remove the stubble left on the whole plot. The stubble removal time was June 5, 2015; Sowing and fertilization; the sowing variety is Zhongdan 909, the corn row spacing is 60cm, the plant spacing is 27cm, and the density is 4117 plants / mu; the corn base is 16-16-16 compound fertilizer 50 kg / mu, and the sowing time is June 8, 2015 , topdressing urea 15 kg / mu in the bell mouth period of corn. On October 5, 2015, the corn was harvested, and the yield was calculated. At the same time, the soil in the plow layer was collected to measure the fertility characteristics.

Embodiment approach

[0025] Embodiment of the present invention: a method for mechanical stubble removal and straw returning to the field, the specific operation steps are as follows:

[0026] After the wheat crops were harvested, the stubble left on the whole plot was removed with a stubble machine. The stubble removal time was June 5, 2015; the straw was crushed during the stubble removal process, and some of the crushed straw was mixed into the surface soil In the process, the remaining straw was left on the surface; after the stubble was removed, half of the total amount of straw was concentrated on 1 / 5 of the plot with a columbine rake, and the seed fertilizer was used on the plot where the straw was collected (straw reduction and returning to the field). The all-in-one machine is used for corn sowing and fertilization, the sowing variety is Zhongdan 909, the corn row spacing is 60cm, the plant spacing is 27cm, and the density is 4117 plants / mu; the corn base is 16-16-16 compound fertilizer 50...

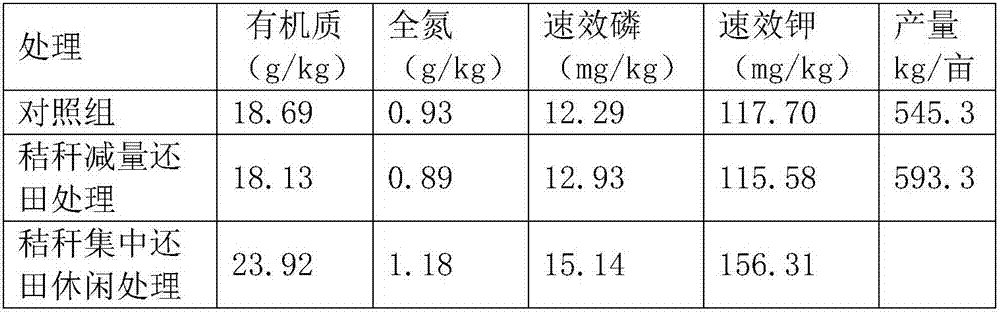

Embodiment 2

[0033] Location: Houlou Village, Zhuangzhou Office, Mengcheng County, Anhui Province. Soil for test: Shajiang black soil. Rotation of wheat and corn.

[0034] Control group (full amount of straw returned directly to the field): After the wheat crops were harvested, the stubble machine was used to remove the stubble left on the whole plot. The stubble removal time was June 5, 2015; Fertilization; the sowing variety is Zhongdan 909, the corn row spacing is 60cm, the plant spacing is 27cm, and the density is 4117 plants / mu; the corn base is 16-16-16 compound fertilizer 50 kg / mu, and the sowing time is June 8, 2015. Topdressing urea 15 kg / mu in the horn-mouth stage of corn. On October 5, 2015, the corn was harvested, and the yield was calculated. At the same time, the soil in the plow layer was collected to measure the fertility characteristics.

[0035]Embodiment of the present invention: After the wheat crops are harvested, the stubble machine is used to remove the stubble le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com