Special steamed bun powder for diabetes and preparation method and application thereof

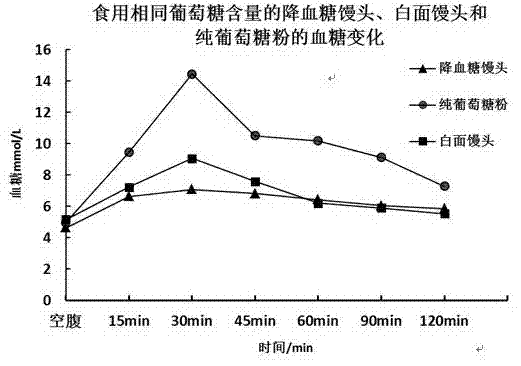

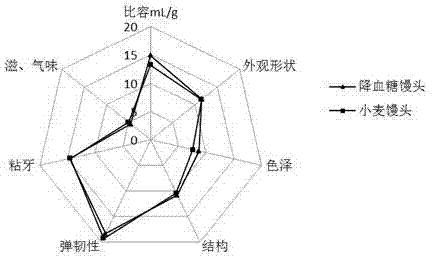

A technology of steamed bread flour and diabetes, which is applied in the field of diabetic steamed bread flour and its preparation, can solve the problems of poor elasticity and fluidity of dough, poor expansion ability of gluten network, and poor structural shape of steamed bread, so as to delay digestion and strengthen Effect of satiety and slowing down of digestion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Wheat Flour: 25g, Oat Flour: 5g, Black Rice Flour: 5g, Buckwheat Flour: 5g, Okara Flour: 8g, Brown Rice Flour: 5g, Potato Starch: 4g; Improver: Trehalose: 3g; Xylitol: 1g, Gluten Powder 6g, yeast: 0.3g, the rest of water. (The sum of all substances in the formula is calculated according to 100g)

[0070] The specific preparation method of steamed bread:

[0071] Kneading dough: activate the yeast with an appropriate amount of warm water (38 ℃) for 3 minutes, pour it into the mixed powder, first stir at low speed for 1 min-2 min at the first speed, after the flour and water are evenly mixed, change to the second speed and stir for 5 min-10 min to The surface of the dough is smooth and not sticky, and it is better not to contain raw flour in the dough.

[0072] Dough fermentation: Put the reconciled dough in a proofing box with a temperature of 38-40 ℃ and a relative humidity of 70-90%, and ferment for about 1 hour until the dough doubles in volume and has a honeycomb-l...

Embodiment 2

[0078] Wheat Flour: 20g, Oat Flour: 6g, Black Rice Flour: 6g, Buckwheat Flour: 6g, Okara Flour: 6g, Brown Rice Flour: 5g, Potato Starch: 4g; Improver: Trehalose: 3g; Xylitol: 1g, Gluten Powder 4g, yeast: 0.3g, the rest of water. (The sum of all substances in the formula is calculated according to 100g)

[0079] The specific preparation method of steamed bread:

[0080] Kneading dough: activate the yeast with an appropriate amount of warm water (38 ℃) for 3 minutes, pour it into the mixed powder, first stir at low speed for 1 min-2 min at the first speed, after the flour and water are evenly mixed, change to the second speed and stir for 5 min-10 min to The surface of the dough is smooth and not sticky, and it is better not to contain raw flour in the dough.

[0081] Dough fermentation: Put the reconciled dough in a proofing box with a temperature of 38-40 ℃ and a relative humidity of 70-90%, and ferment for about 1 hour until the dough doubles in volume and has a honeycomb-l...

Embodiment 3

[0086] Wheat flour: 30g, oat flour: 5g, black rice flour: 5g, buckwheat flour: 5g, okara powder: 5g, brown rice flour: 5g, potato starch: 4g; improver: trehalose: 3g; xylitol: 0.5g, grain Protein powder 4g, yeast: 0.3g, the balance of water. (The sum of all substances in the formula is calculated according to 100g)

[0087] The specific preparation method of steamed bread:

[0088] Kneading dough: activate the yeast with an appropriate amount of warm water (38 ℃) for 3 minutes, pour it into the mixed powder, first stir at low speed for 1 min-2 min at the first speed, after the flour and water are evenly mixed, change to the second speed and stir for 5 min-10 min to The surface of the dough is smooth and not sticky, and it is better not to contain raw flour in the dough.

[0089] Dough fermentation: Put the reconciled dough in a proofing box with a temperature of 38-40 ℃ and a relative humidity of 70-90%, and ferment for about 1 hour until the dough doubles in volume and has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com