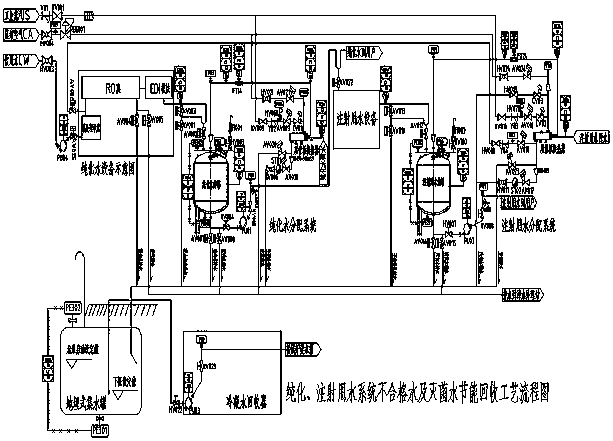

Energy-saving recovery system for unqualified water and sterilized water in purification and injection water systems

A water for injection and recovery system technology, applied in the field of biomedicine, can solve the problems of increasing industrial wastewater discharge, waste discharge, etc., and achieve the effect of saving energy consumption for initial heating, saving energy consumption for cooling, and avoiding energy consumption for cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

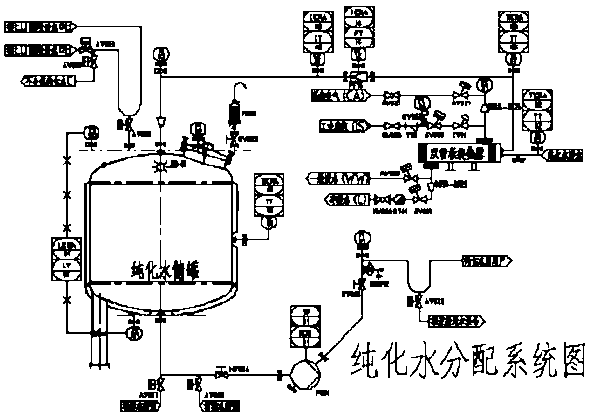

[0046] Valve initial state: HV001, HV002, HV003, HV004, HV005, HV006, HV007, HV008, HV009, HV021, HV010, HV011, HV018, HV019, HV016, HV022, HV023, HV024, HV060, HV070 are valve adjustment 1 valve open, Suitable state, other valves are closed;

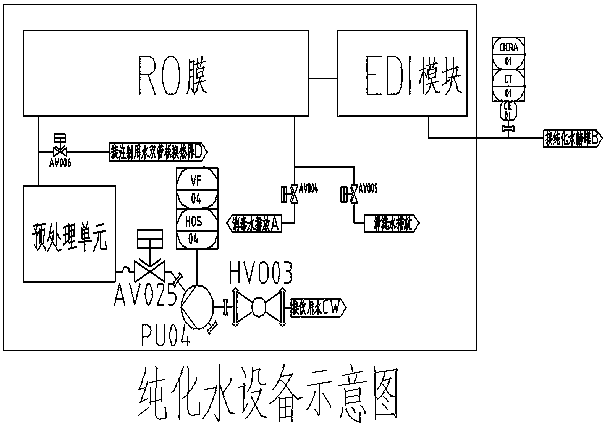

[0047] Operation mode of collection and utilization of unqualified water generated during the preparation process of purified water equipment:

[0048] 1. When the purified water equipment produces water normally, the valves AV002 and AV003 are in the open state;

[0049] 2. In the initial stage of startup and working process of the purified water equipment, if the conductivity sensor CE01 monitors that the conductivity of the purified water effluent exceeds the standard, AV002 and AV003 are turned off, and AV001 is turned on at the same time;

[0050] 3. At this time, the unqualified water produced by the purified water equipment flows into the collection pipe network to the buried water collection tank by itself;

[0051] 4. The col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com