One-pot preparation method for photodegradation of impurities Ⅰ, Ⅱ, ⅳ, ⅳ of sarcogrelate hydrochloride

A technology of sarpogrelate hydrochloride and photodegradation, applied in the field of medicine, can solve problems such as low efficiency, and achieve the effects of high efficiency, high utilization rate of raw materials and few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

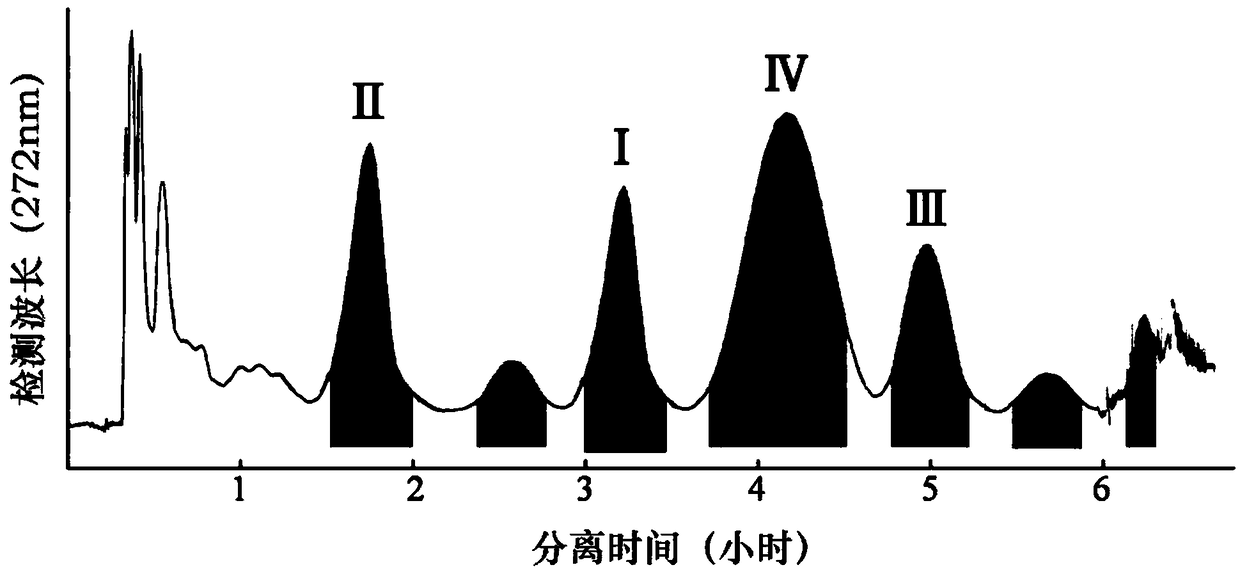

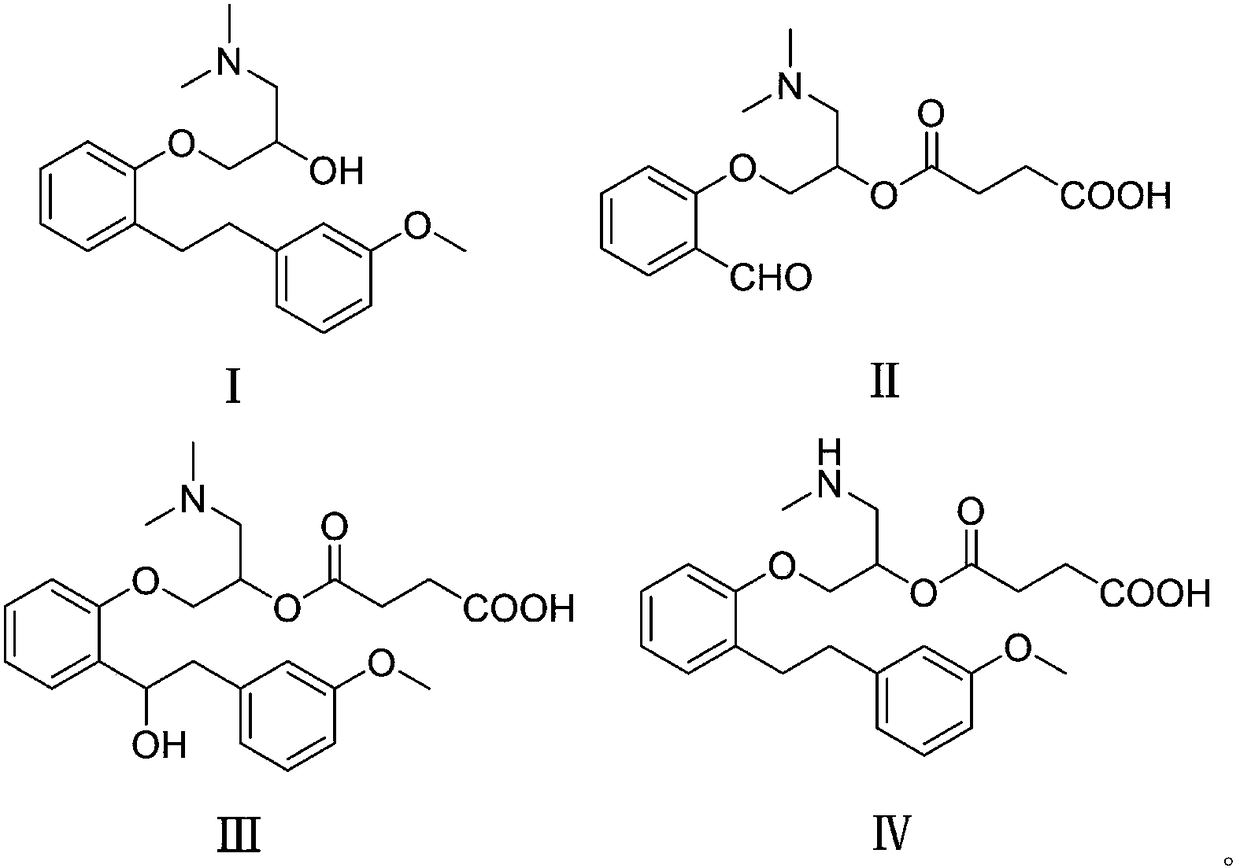

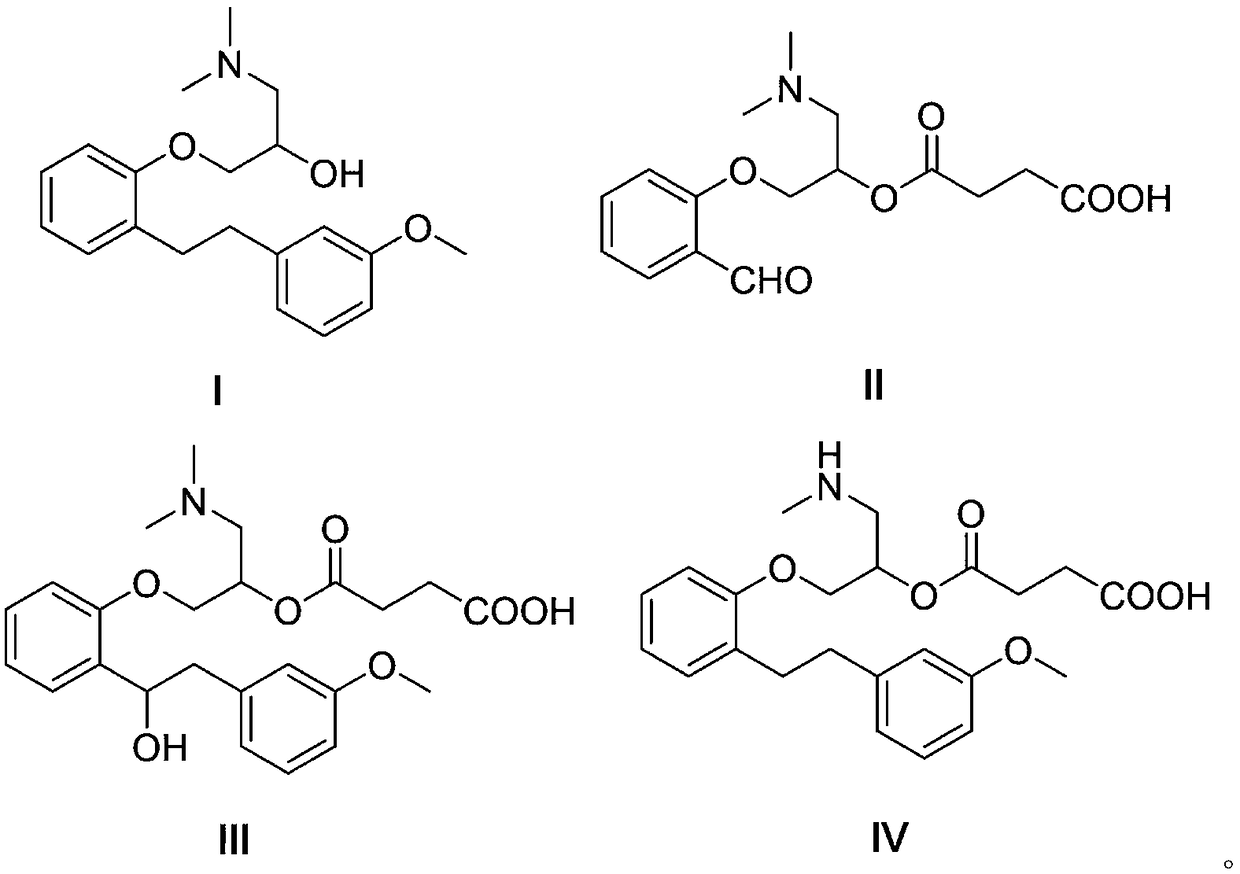

[0025] Example 1 Preparation and Separation of Photodegradation Impurities I, II, III, and IV

[0026] Preparation method of degradation mixture:

[0027] Dissolve 60mg of sargrelate hydrochloride in water to prepare a 3mg / mL solution, heat it at 85°C for 1.5 hours, and then irradiate it with 1,200,000 lux cool white fluorescent lamps for 5 hours and 200 Wh / m2 ultraviolet fluorescent lamps After irradiating for 4 hours, the degraded solution was concentrated and frozen until dry to obtain a degraded mixture.

[0028] High-speed countercurrent separation of degradation mixtures:

[0029] Prepare the ethyl acetate-ethanol-water-formic acid (4:1:5:0.025, v / v / v / v) solvent system 12 hours before the separation. The specific preparation method is: mix the four solvents in proportion, and shake vigorously , let it stand for 12 hours to completely separate the upper and lower phases in the funnel, the upper phase is used as a stationary phase, and the lower phase is used as a mobile...

Embodiment 2

[0033] Example 2 Preparation and separation of photodegradation impurities Ⅰ, Ⅱ, Ⅲ, Ⅳ

[0034] Preparation method of degradation mixture:

[0035] Dissolve 60mg of sargrelate hydrochloride in water to prepare a 2mg / mL solution, heat it at 80°C for 2 hours, and then irradiate it with 1,200,000 lux cool white fluorescent lamps for 4 hours, 200 Wh / m2 ultraviolet fluorescent lamps After irradiating for 5 hours, the degraded solution was concentrated and frozen until dry to obtain a degraded mixture.

[0036] High-speed countercurrent separation of degradation mixtures:

[0037] Prepare the ethyl acetate-ethanol-water-formic acid (4:1:5:0.025, v / v / v / v) solvent system 12 hours before the separation. The specific preparation method is: mix the four solvents in proportion, and shake vigorously , let it stand for 12 hours to completely separate the upper and lower phases in the funnel, the upper phase is used as a stationary phase, and the lower phase is used as a mobile phase, and u...

Embodiment 3

[0041] Example 3 Preparation and Separation of Photodegradation Impurities I, II, III, and IV

[0042] Preparation method of degradation mixture:

[0043] Take 60mg of sargrelate hydrochloride and dissolve it in water to prepare a 4mg / mL solution, heat it at 90°C for 1 hour, and then irradiate it with 1,200,000 lux cool white fluorescent lamp for 6 hours, 200 Wh / m2 ultraviolet fluorescent lamp After irradiating for 3 hours, the degraded solution was concentrated and frozen until dry to obtain a degraded mixture.

[0044] High-speed countercurrent separation of degradation mixtures:

[0045] Prepare the ethyl acetate-ethanol-water-formic acid (4:1:5:0.025, v / v / v / v) solvent system 12 hours before the separation. The specific preparation method is: mix the four solvents in proportion, and shake vigorously , let it stand for 12 hours to completely separate the upper and lower phases in the funnel, the upper phase is used as a stationary phase, and the lower phase is used as a mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com