Foam sterilization detergent used for food devices, and preparation method thereof

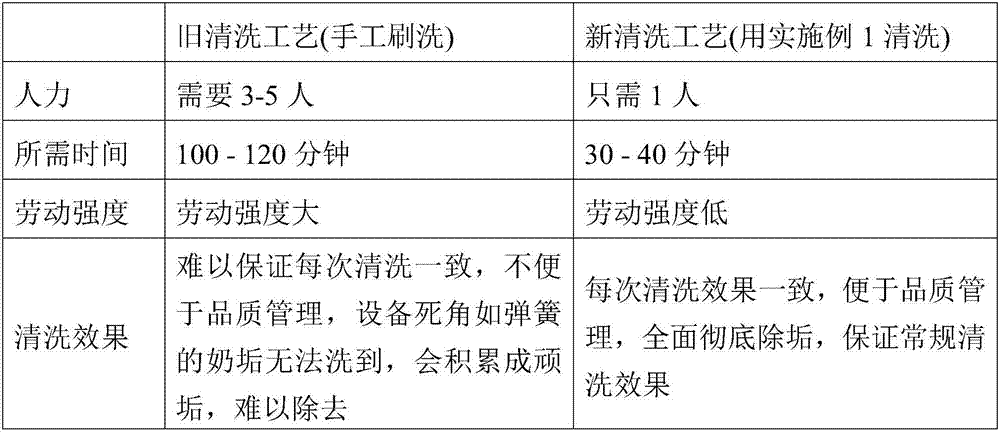

A technology of sterilizing cleaning agent and food equipment, which is applied in the field of cleaning agent, and can solve the problems that affect the hygienic index and product quality of dairy products, the discount of manual cleaning effect, and the breeding and reproduction of bacteria, so as to achieve excellent dirt moistening, ensure hygiene and quality, and foam rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

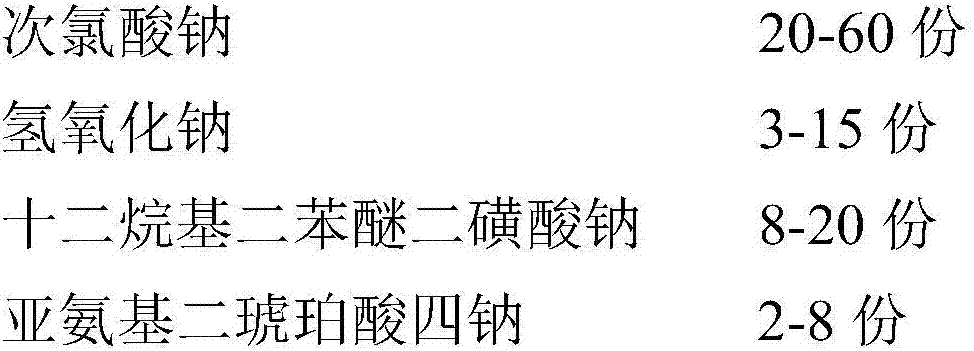

Embodiment 1

[0041] A kind of preparation method of foam sterilization cleaning agent, described preparation method comprises the steps:

[0042] (1) Add 80 parts of deionized water into a clean stainless steel pot and stir;

[0043] (2) Add 8 parts of tetrasodium iminodisuccinate (active matter content 76%, pH value of 1% aqueous solution is 10.5), and stir for 30 minutes at a speed of 1000 rpm until completely dissolved;

[0044] (3) Add 15 parts of sodium hydroxide (purity 96%), 5 parts of sodium polyaspartate (solid content 40%, the pH value of 1% aqueous solution is 9.0), open cooling circulating water simultaneously, 800 rev / min Under the rotating speed, stir for 10-20 minutes until completely dissolved and evenly;

[0045] (4) After the solution in the stainless steel pot is cooled to 28° C., add 60 parts of sodium hypochlorite (10 wt % sodium hypochlorite solution), and stir for 20 minutes until uniformly mixed at a speed of 800 rpm;

[0046] (5) Add 20 parts of sodium dodecyl di...

Embodiment 2

[0050] A kind of preparation method of foam sterilization cleaning agent, described preparation method comprises the steps:

[0051] (1) Add 50 parts of deionized water into a clean stainless steel pot and stir;

[0052] (2) Add 2 parts of tetrasodium iminodisuccinate (active matter content 78%, pH value of 1% aqueous solution is 11.5), stir at 500 rpm for 20 minutes until completely dissolved;

[0053] (3) Add 3 parts of sodium hydroxide (purity 96%), 1 part of sodium polyaspartate (solid content is 42%, the pH value of 1% aqueous solution is 11.0), and open the cooling circulating water at the same time, 200 rpm Stir for 10 minutes at a high speed until it is completely dissolved;

[0054] (4) After the solution in the stainless steel pot is cooled to 25° C., add 20 parts of sodium hypochlorite (10 wt % sodium hypochlorite solution), and stir for 10 minutes until uniformly mixed at a speed of 200 rpm;

[0055] (5) Add 8 parts of sodium dodecyl diphenyl ether disulfonate (e...

Embodiment 3

[0059] A kind of preparation method of foam sterilization cleaning agent, described preparation method comprises the steps:

[0060] (1) Add 65 parts of deionized water into a clean stainless steel pot and stir;

[0061] (2) Add 5 parts of tetrasodium iminodisuccinate (the active substance content is 77%, the pH value of 1% aqueous solution is 11), and stir for 25 minutes at a speed of 750 rpm until completely dissolved;

[0062] (3) Add 9 parts of sodium hydroxide (purity 96%), 3 parts of sodium polyaspartate (solid content is 41%, the pH value of 1% aqueous solution is 10.0), open cooling circulating water simultaneously, 500 rpm Under the speed of rotation, stir for 15 minutes until completely dissolved and evenly;

[0063] (4) After the solution in the stainless steel pot is cooled to 30° C., add 40 parts of sodium hypochlorite (10 wt % sodium hypochlorite solution), and stir for 15 minutes until uniformly mixed at a speed of 500 rpm;

[0064] (5) Add 14 parts of sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com