Microcapsule for carbonless copy paper and preparation method thereof and carbonless copy paper and paint thereof

A technology of carbon-free copy paper and microcapsules, which is applied in the field of papermaking, can solve the problem of thin writing line width, and achieve the effect of improving spreadability and increasing line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

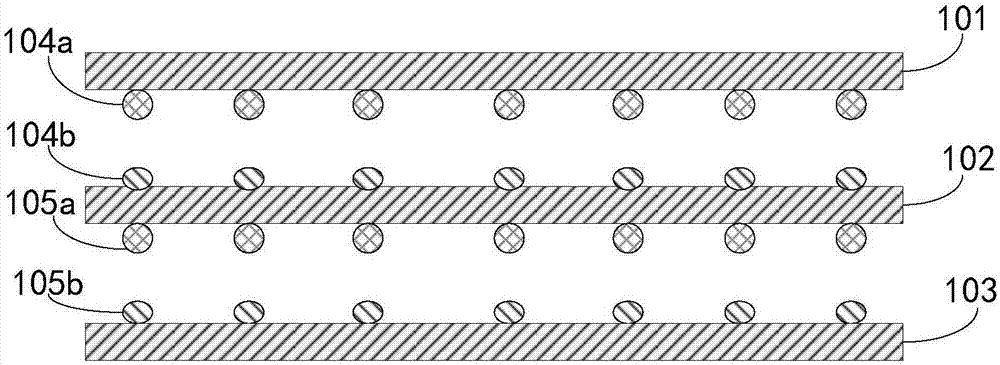

[0021] In a specific application scenario, the preparation method of the microcapsules for carbonless copy paper provided by the present invention comprises the following steps:

[0022] A, the leuco dye of 2-10 mass parts (for example 2,5,8,10 mass parts etc.), the solvent naphtha of 20-80 mass parts (for example 20,40,60,80 mass parts etc.) 0.01%-0.5% (for example, 0.01%, 0.1%, 0.2%, 0.3%, 0.4%, 0.5%, etc.) of the oil-based dry mass of the oil-soluble surfactant is mixed evenly to obtain the core material of the microcapsule;

[0023] B. The above-mentioned core material, 2-10 parts by mass (such as 2, 5, 8, 10 parts by mass, etc.) The solvent is mixed evenly for preliminary emulsification to obtain an emulsification system mixture. When the particle diameter of the latex particles in the emulsification system mixture reaches 2-8um (such as 2, 5, 8um), add 6-15 parts by mass (such as 6, 9, 12, 15 parts by mass, etc.) of the wall material, fully stirred to obtain the emulsio...

Embodiment 1

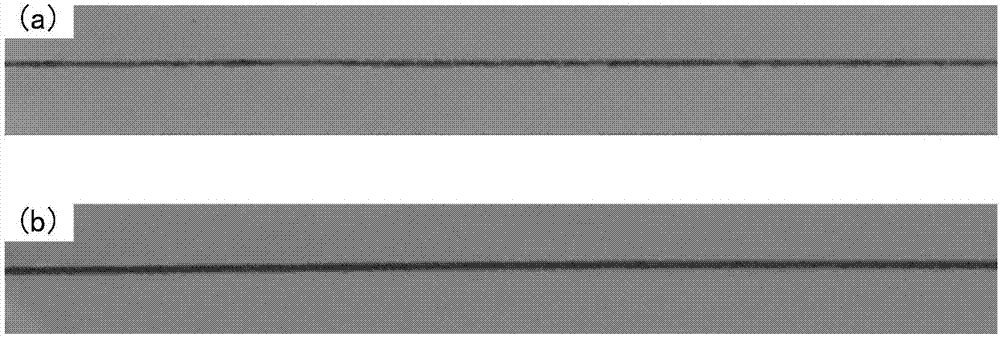

[0030] Embodiment 1 (comparative example)

[0031] A, preparation of microcapsules:

[0032] 3g of leuco dye (commercially available) is dissolved in 70g of mineral spirits under heating and mixed uniformly to obtain a core material;

[0033] Mix the above-mentioned core material, 4.5g polystyrene maleic anhydride emulsifier, and 100g water, and carry out preliminary emulsification to obtain an emulsification system mixture. When the particle size of the latex particles in the emulsification system mixture reaches 4.5um, add 15g of wall material , fully stir into the emulsion;

[0034] The above emulsion is gradually heated up to 65°C-75°C under stirring for curing and molding, and the first pH regulator is added to adjust the pH value of the system to 7.5-10 for storage until use.

[0035] B, prepare carbonless copy paper coating:

[0036] Get the above microcapsules 100g, wheat starch 30g, phosphorylated potato starch 8g, styrene-butadiene latex 3g, polyamide polyurea epi...

Embodiment 2

[0040] The difference between Example 2 and Example 1 is that 0.07 g (accounting for 0.1% of the absolute dry mass of solvent oil) Span-40 was added during the preparation of the microcapsule core material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com