Additive for improving construction performance of wall leveling materials

A construction performance and additive technology, which is used in the field of additives for building construction, and additives to improve the construction performance of leveling materials for interior and exterior walls of buildings, can solve the problems of high cost of leveling materials for walls, heavy construction feel, and slow construction speed. , to achieve the effect of increased strength, reasonable formula and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1. Formula (by weight)

[0015] Anionic polyacrylamide (molecular weight: 10 million) 0.1%

[0016] C18 normal alkanes 40%

[0017] Higher Fatty Acid Potassium Salt 35%

[0018] Distilled water 24.9%

[0019] 2. Preparation

[0020] According to the above formula, add polyacrylamide and distilled water into a mechanical mixer, stir at a high speed of 800 rpm for 15 minutes, then add higher fatty acid potassium salt and C18 normal alkanes, stir for 20 minutes until uniform, and obtain a paste with a viscosity of 112.5KU Additive 1.

[0021] 3. Application

[0022] Add the above-mentioned additive 1 to the putty paste in the process of adding water and stirring, the amount of water is 54% of the weight of the putty paste, and the formula (by weight) of the putty paste is:

[0023] Heavy calcium 93.3%

[0024] Bentonite 3%

[0025] Pregelatinized starch 0.4%

[0026] Carboxymethylcellulose 1.3%

[0027] Lotion 2%

[0028] 4. Performance test

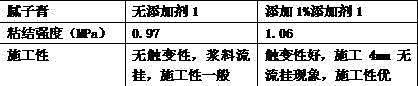

[0029] The putty ...

Embodiment 2

[0033] 1. Formula (by weight)

[0034] Anionic polyacrylamide (molecular weight: 12 million) 0.15%

[0035] C16 normal alkanes 25%

[0036] Higher Fatty Acid Potassium Salt 50%

[0037] Distilled water 24.85%

[0038] 2. Preparation

[0039] According to the above formula, add polyacrylamide and distilled water into a mechanical mixer, stir at a high speed of 900 rpm for 15 minutes, then add higher fatty acid potassium salt and C18 normal alkanes, stir for 20 minutes until uniform, and obtain a paste with a viscosity of 135.6KU Additive 2.

[0040] 3. Application

[0041] The above-mentioned liquid additive 2 is applied to construction glue, and the formula (by weight) of construction glue is:

[0042] Polyvinyl alcohol 2%

[0043] Carboxymethylcellulose 0.5%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com