Sealing device for large rolling bearing and wind-driven generation device

A rolling bearing, a large-scale technology, applied in the direction of rolling contact bearings, engine sealing, wind power generation, etc., can solve the problem that the metal wire can not perfectly improve the sealing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

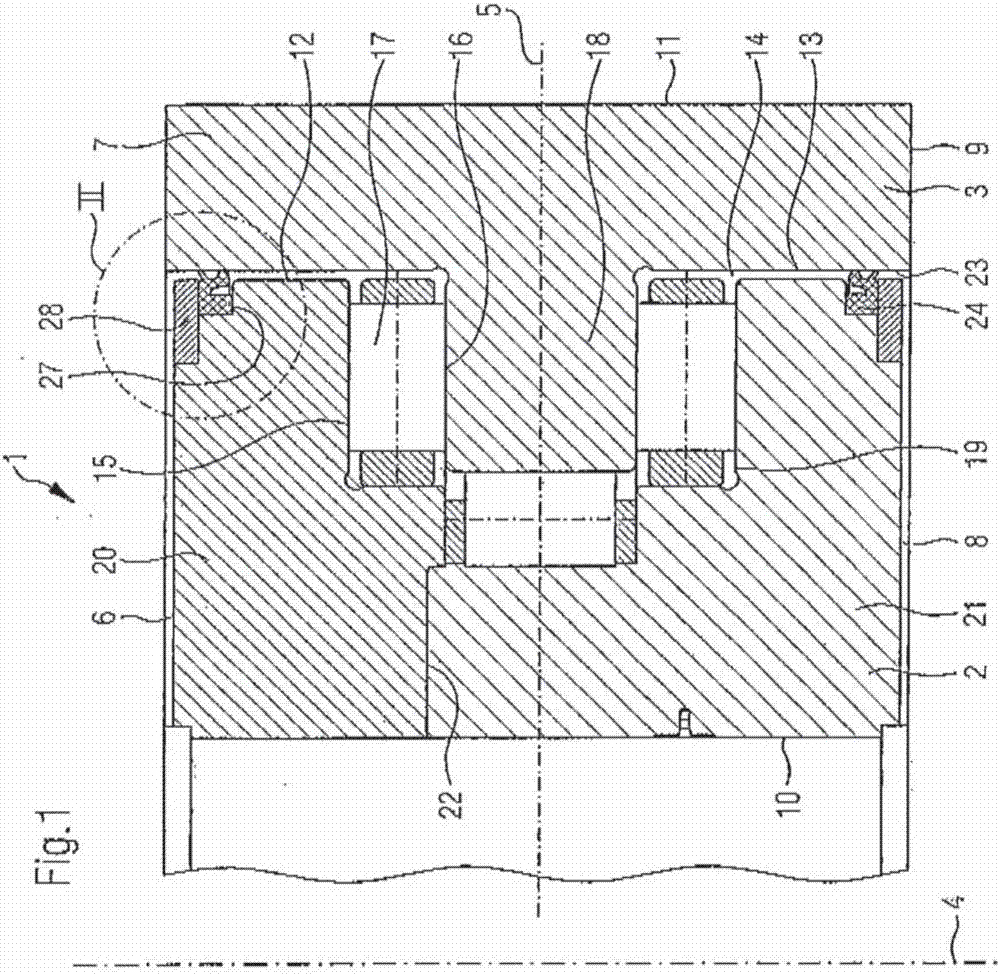

[0078] The drawing shows a rotary bearing 1 with two annular coupling elements 2 , 3 which are arranged radially one above the other. In the center of the two coupling elements 2 , 3 there is a bearing axis of rotation 4 , about which the two coupling elements 2 , 3 can rotate relative to each other. The bearing axis of rotation 4 runs at right angles through the base surface 5 of the rotary bearing 1 , which extends approximately centrally between the flat end sides 6 , 7 , 8 , 9 of the coupling elements 2 , 3 .

[0079] Fastening bores for fastening the two coupling elements 2 , 3 by means of screws or bolts to a respective coupling structure, for example to a machine part or plant part or the like, are not shown. For this purpose, on each coupling element 2 , 3 , a plurality of blind holes are provided in the flat end faces 6 , 7 , 8 , 9 of the coupling elements 2 , 3 in a circular distribution around the bearing axis of rotation 4 . It preferably has an internal thread fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com