High stress contact lubricant oil film frictional force simulation measurement device

A measuring device and friction force technology, applied in the direction of measuring device, force/torque/work measuring instrument, using stable tension/pressure to test the strength of materials, etc. The accuracy of oil anti-friction and anti-wear performance is not high, and the temperature is easily affected by the external environment, etc., to achieve the effect of improving operational flexibility, ingenious design concept, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

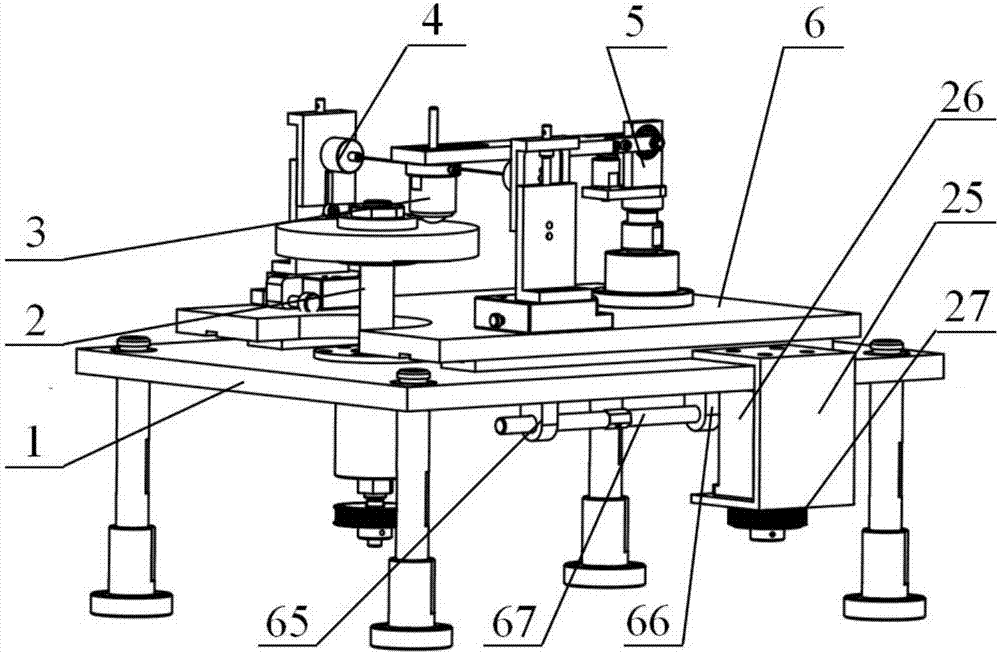

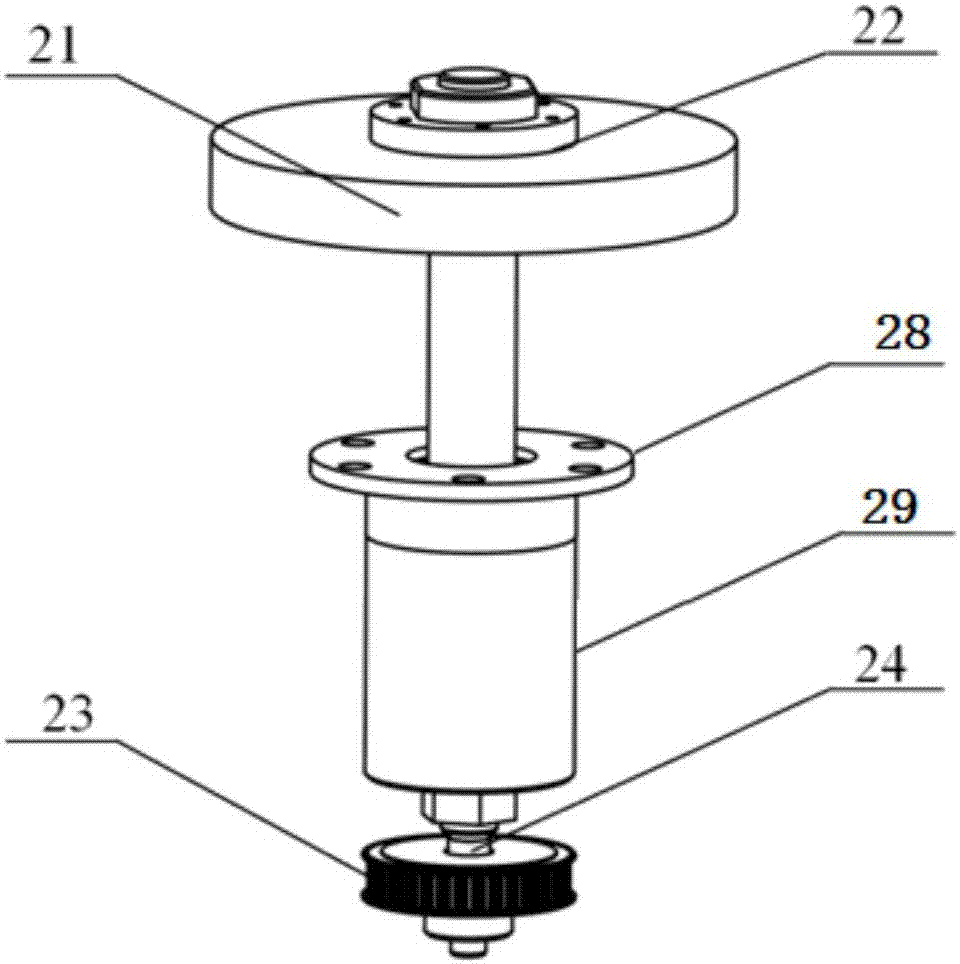

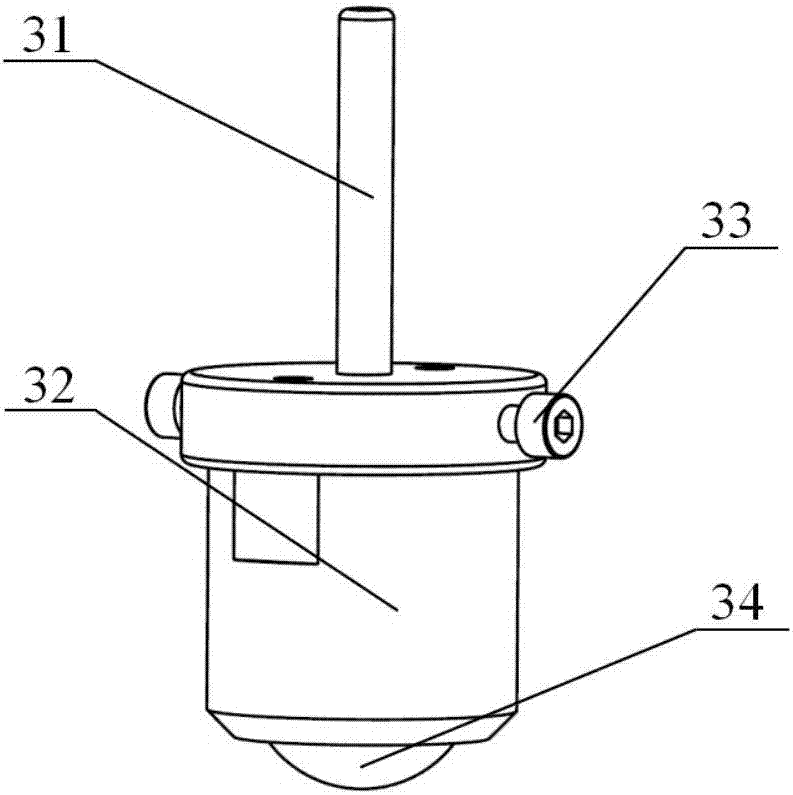

[0034] The main structure of the analog measurement device for the high-stress contact lubricating oil film friction force involved in this embodiment includes: a support platform 1, a disk drive device 2, a steel ball fixing device 3, a sensor fixing and adjusting device 4, a loading and rotating device 5 and translation device 6; the support platform 1 is a four-leg support structure at the bottom, and the upper ends of the four support feet are respectively fixedly connected to the four corners of the table top 61; the disc drive device 2 is fixedly placed on the upper surface of the support platform 1 near the front edge , its main structure includes: round steel disc 21, fixing device 22, driven pulley 23, driven shaft 24, disc drive motor support 25, disc drive motor 26, timing pulley 27, fixed disc 28 and sleeve 29 The round steel disc 21 is fixedly placed on the upper end of the driven shaft 24, and the upper end of the round steel disc 21 is equipped with a circular fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap