Top-emitting organic electroluminescence diode display device and manufacture method therefor

A luminescence and top-emission technology, which is applied in the direction of organic semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of open circuit metal, uneven brightness of display screen, and inability to form ohmic contact, etc., to reduce resistance, The effect of increasing the image refresh rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

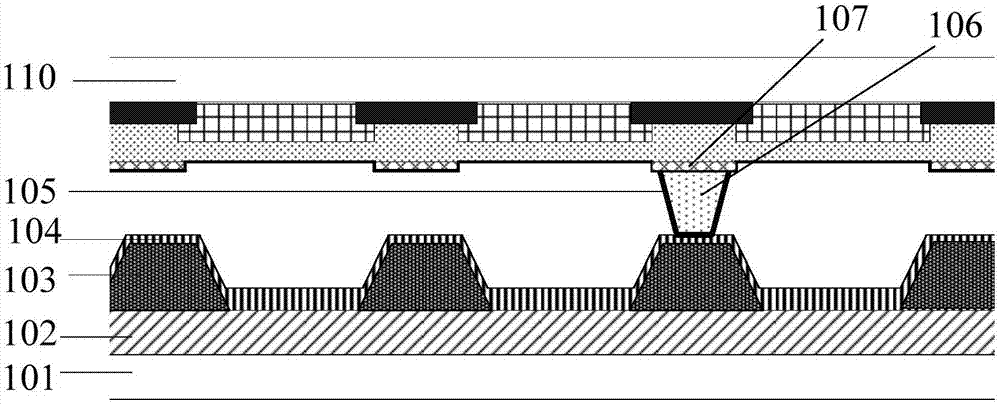

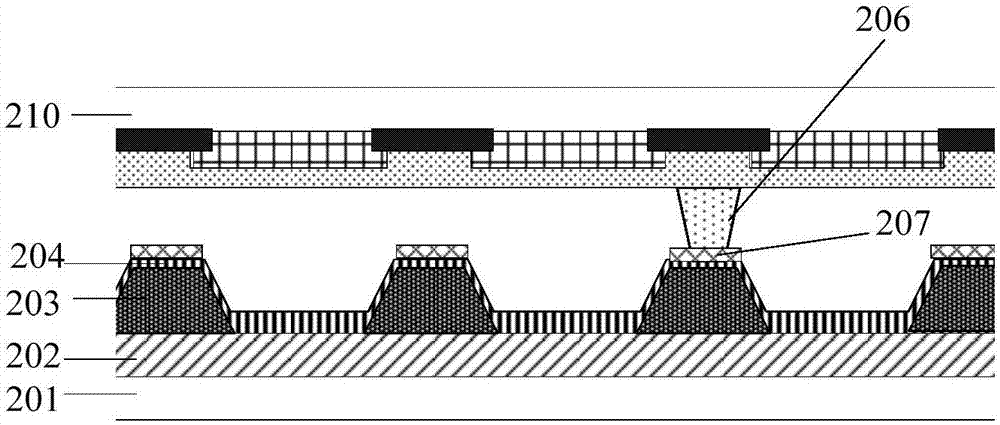

[0027] This embodiment provides a top emission organic electroluminescent diode display device. image 3 is a schematic structural view showing a top emission organic electroluminescent diode display device according to an embodiment of the present invention.

[0028] Such as image 3 As shown, the top emission organic electroluminescent diode display device includes: a glass substrate 201, a thin film transistor substrate 202 arranged on the glass substrate; a pixel definition layer 203, arranged on the thin film transistor substrate 202, an organic light emitting layer (not shown in the figure) out), arranged on the thin film transistor substrate; the cathode layer 204 is arranged on the organic light-emitting layer, covering the pixel definition layer 203, and the cathode auxiliary layer 207 is arranged on the cathode layer 204, and the position of the cathode auxiliary layer 207 is the same as that of the The positions of the pixel definition layer 203 correspond to each ...

Embodiment 2

[0034] This embodiment provides a method for manufacturing a top emission organic electroluminescent diode display device. Figure 4 It is a process flow diagram showing a method for manufacturing a top emission organic electroluminescent diode display device according to an embodiment of the present invention.

[0035] Such as Figure 4 As shown, the method includes the following steps.

[0036] In step S401 , forming a thin film transistor substrate includes cleaning the substrate by a standard method, and performing a preparation process of the thin film transistor.

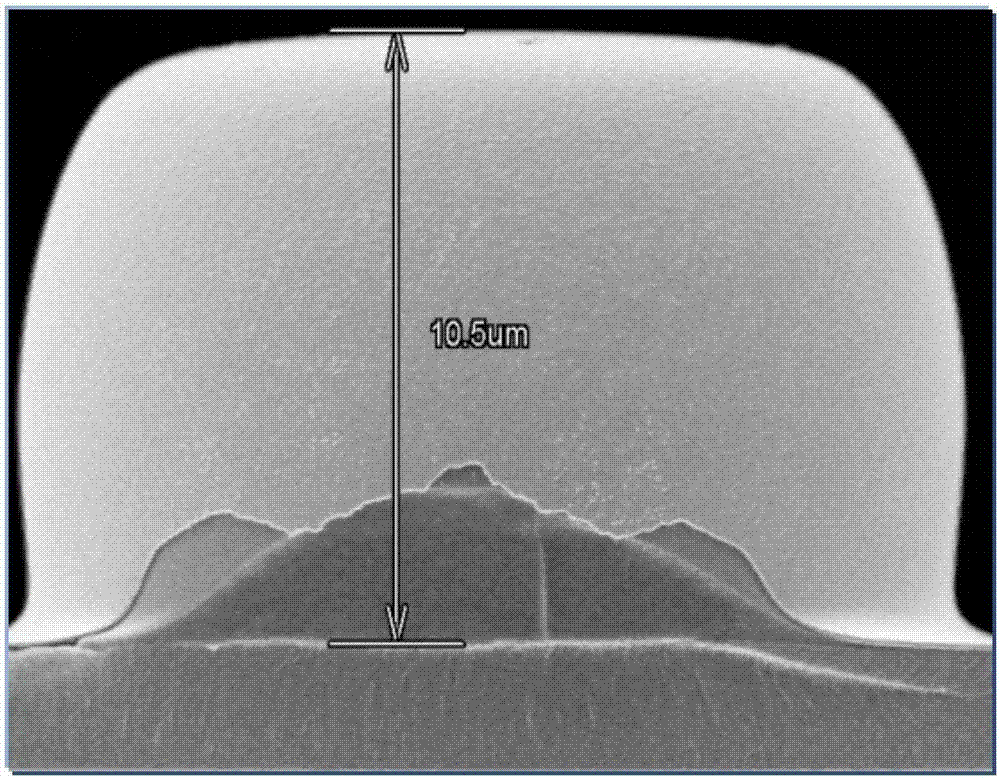

[0037] In step S402, a pixel definition layer and an organic light emitting layer are formed on the thin film transistor substrate. It includes: coating a layer of light-curing material in a spin coating manner, with a thickness between 1.6 microns and 2.0 microns. Pre-baking, exposure, development, post-baking, and patterning processes are performed to prepare a pixel definition layer; and an organic light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com