Strand-rolling structural units and simulated manual hollow vermicelli strand making machine equipped with the strand-rolling structural units

A technology for a strip making machine and components, which is applied in the field of manual hollow dried noodle making machines, can solve the problems of increased salt content of dried noodles, high production cost, troublesome production process, etc., so as to improve work efficiency, improve work efficiency and ensure taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

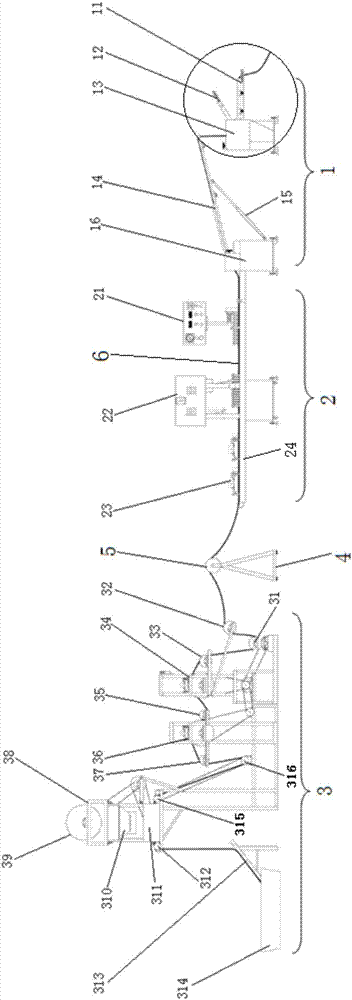

[0048] combine Figure 1-5 , 9 and 12, the manual hollow noodle making machine of the present embodiment includes a tablet buffer unit 1, a first hollow rubbing unit 2, a buffer frame 4, a buffer shaft 5 and a second hollow rubbing unit arranged in sequence along the length direction 3. Tabletting buffer unit 1 mainly performs tableting and conveying of the strip surface to be made, the first hollow rubbing unit 2 mainly rolls and rubs the sheet surface for the first time, buffer frame 4 and buffer shaft 5 are used for Connect the first hollow rubbing unit 2 and the second hollow rubbing unit 3 to provide buffer time for twice rubbing, the second hollow rubbing unit 3 mainly carries out secondary rubbing to the noodles after rubbing for the first time, and to the second The noodles after the first rubbing are sprinkled and buffered; specifically:

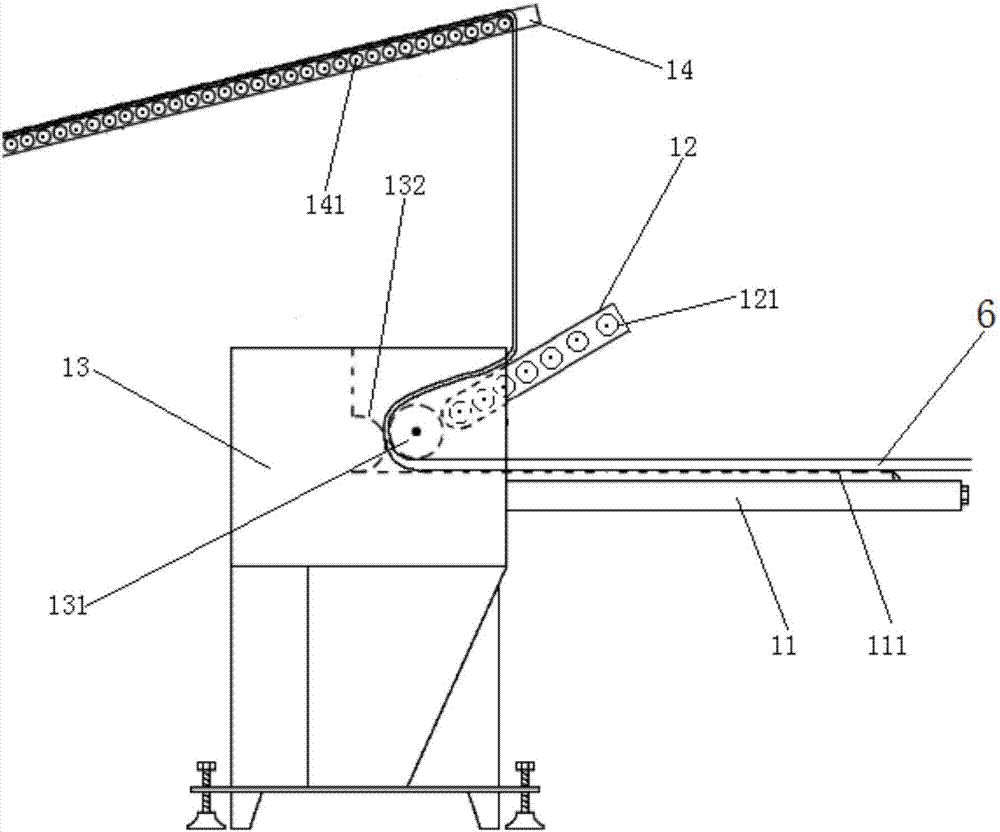

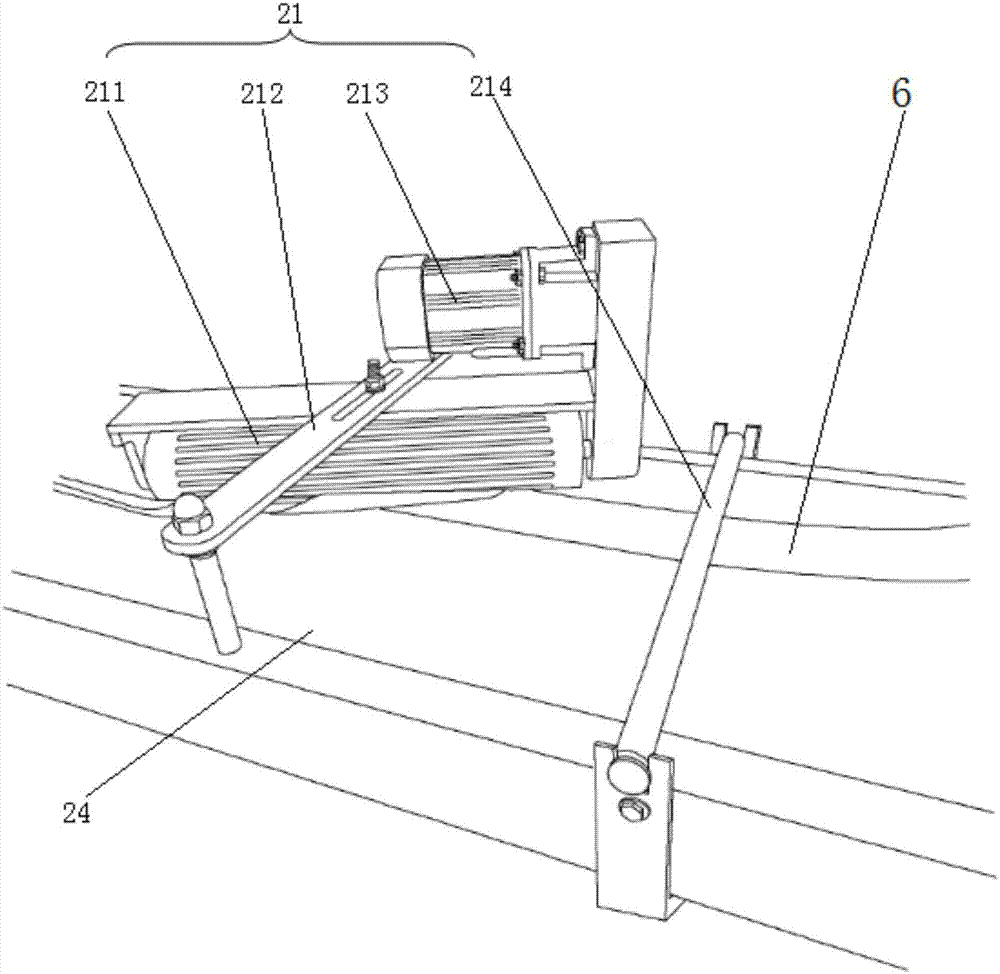

[0049] Tablet pressing buffer unit 1 includes a first transfer table 11, a conveyor belt 111, a second transfer table 12, a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com