Preparation method of electrostatic spinning hollow fiber membrane

A technology of electrospinning and electrospinning process, which is applied in the field of preparation of electrospinning hollow fiber membranes, can solve problems such as complex operation steps, influence of hollow fiber performance, and incomplete removal of core layer materials, and achieve high separation accuracy , Improve the bonding strength, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

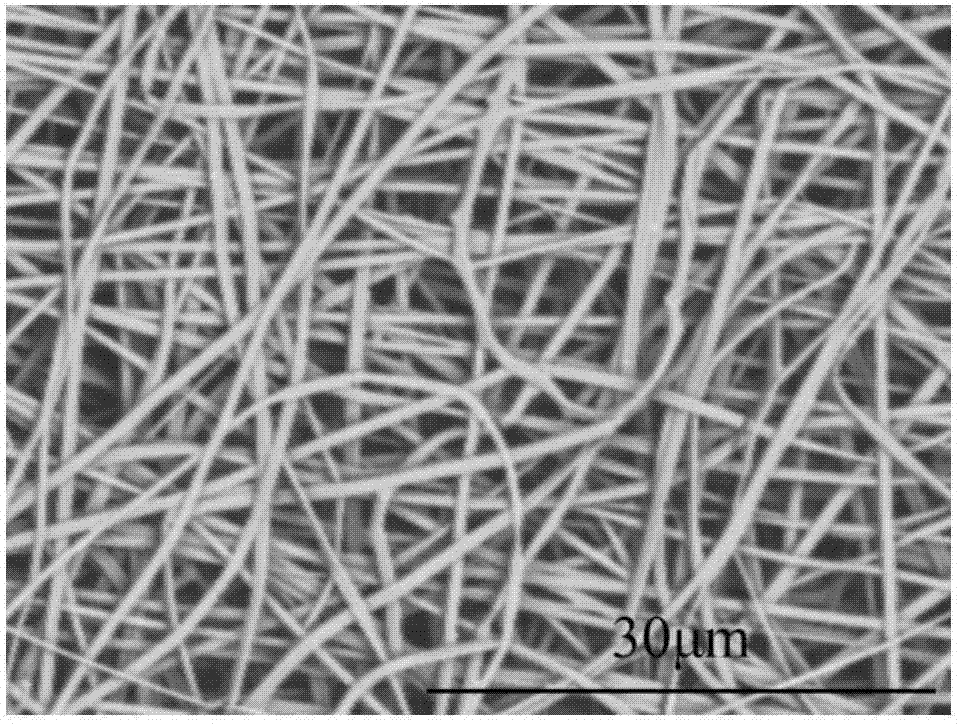

[0025] The invention provides a method for preparing an electrospun hollow fiber membrane, which is characterized in that it comprises the following steps:

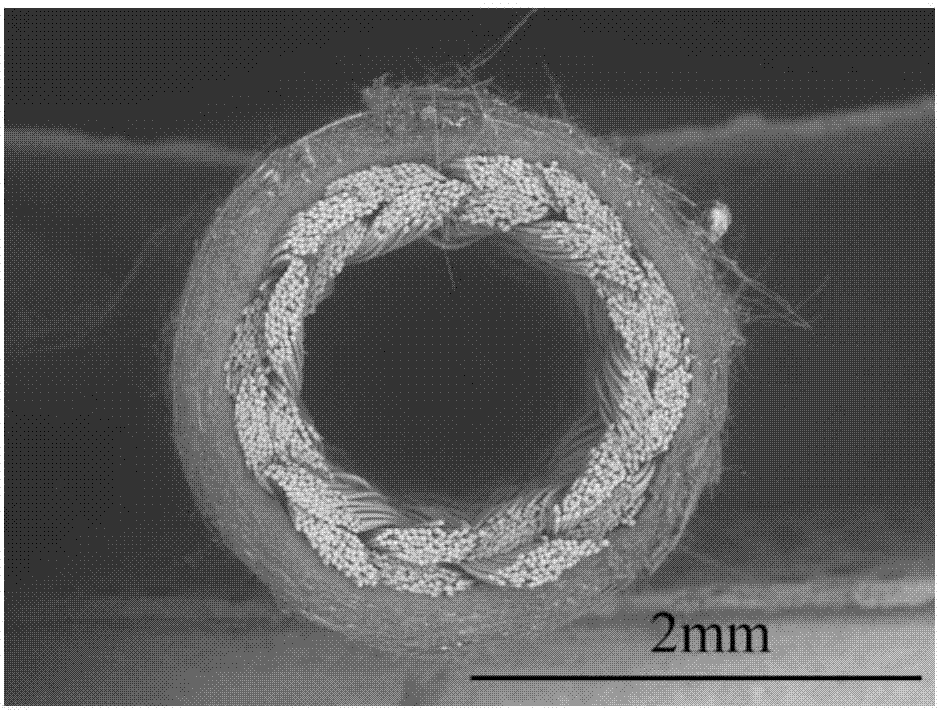

[0026] A. Preparation of hollow braided tube: use two-dimensional braiding technology to weave fiber filaments into a hollow braided tube, and use the hollow braided tube as a reinforcement for electrospinning hollow fiber membranes;

[0027] The fiber filaments are at least one of polyacrylonitrile filaments, polyester filaments, polyamide filaments or polypropylene filaments; the weaving pitch is 1-3mm, the speed of the two-dimensional braiding machine is 500-1500rpm, and the pitch The smaller, the thinner the hollow braided tube;

[0028] B. Preparation of spinning solution: dissolving 5-20wt% polymer resin and 0-10wt% additive in 70-95wt% solvent to form spinning solution, the sum of each component being 100wt%;

[0029] The polymer resin is a conventional fiber-forming polymer, such as at least one of polyacrylonitr...

Embodiment 1

[0037] A. Fabrication of Hollow Braided Tubes

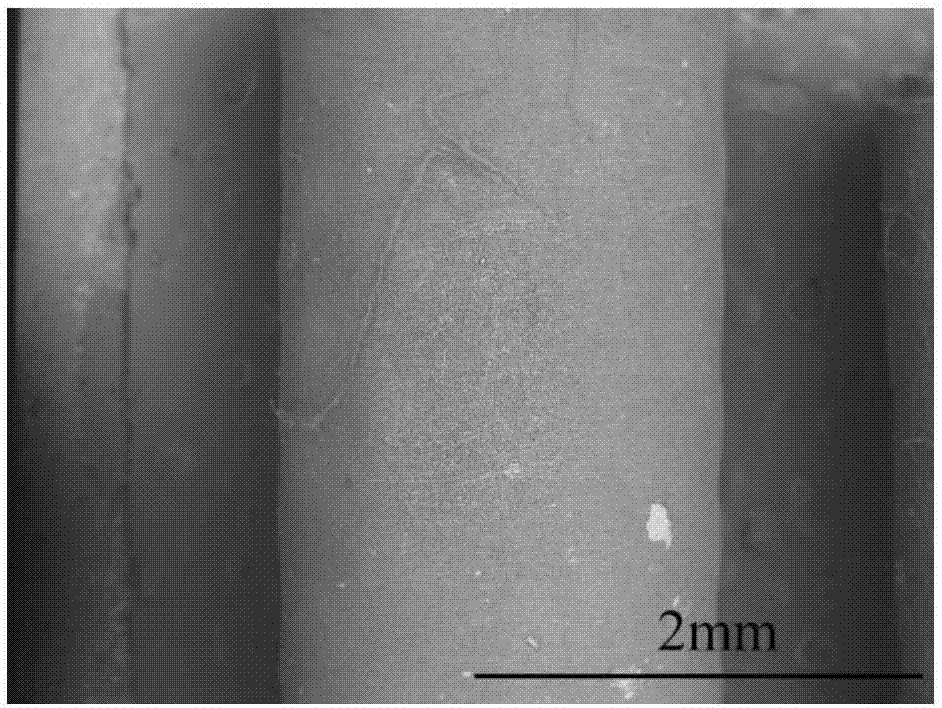

[0038]Using a 24-spindle two-dimensional braiding machine, set the braiding pitch to 2 mm, and the rotation speed to 800 rpm, to braid the polyester fiber filaments into a polyester hollow braided tube with an outer diameter of 2.0 mm.

[0039] B. Preparation of spinning solution

[0040] Weigh 5 g of dried polyacrylonitrile resin (model: P1361; molecular weight: 90,000), prepare it into a N,N-dimethylacetamide solution with a polyacrylonitrile mass fraction of 10 wt%, add 2 wt% PEG600, and heat at 75°C Stir for 3 hours to obtain a homogeneous solution, and obtain a spinning solution after vacuum defoaming.

[0041] C. Preparation of electrospinning hollow fiber membrane: Immerse the polyester braided tube in N,N-dimethylacetamide solution with a mass fraction of 1 wt% polyacrylonitrile for 1 min, inject 5 ml of the prepared spinning solution into the electrostatic In the spinning injector device, the spinning parameters are se...

Embodiment 2

[0043] A. Fabrication of Hollow Braided Tubes

[0044] A 24-spindle two-dimensional braiding machine was used to set the braiding pitch to 1 mm and the rotational speed to be 700 rpm to braid polypropylene fiber filaments into a polypropylene hollow braided tube with an outer diameter of 1.6 mm.

[0045] B. Preparation of spinning solution

[0046] Weigh 5 g of dried polyvinylidene fluoride resin (model: Solvay 1002; molecular weight: 90,000) to prepare a N,N-dimethylacetamide solution with a mass fraction of polyvinylidene fluoride of 8 wt%, and add 0.1 wt% Lithium chloride was stirred at 75°C for 3 hours to obtain a homogeneous solution, and the spinning solution was obtained after vacuum defoaming.

[0047] C. Preparation of Electrospun Hollow Fiber Membranes

[0048] Immerse the polypropylene braided tube in the N,N-dimethylacetamide solution with a mass fraction of polyvinylidene fluoride of 2wt% for 1 min, inject the prepared spinning solution into three 5ml electrospi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com