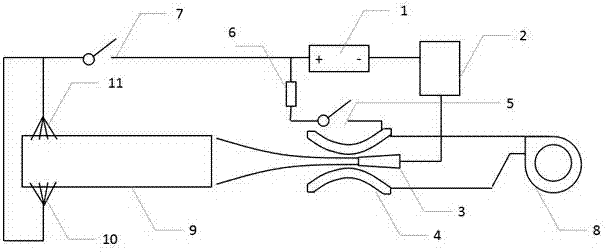

Dual-mode plasma arc device and method for rotating electrode atomization

A plasma arc and rotating electrode technology, applied in the powder metallurgy industry, can solve problems such as low thermal efficiency, and achieve the effects of improving thermal efficiency, improving production efficiency, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for centrifugal atomization of a dual-mode plasma arc device according to claim 1, the working mode of the plasma gun includes two modes of transferred arc and non-transferred arc, and the variable resistance module, the switch module, and the The gas pressure of the plasma gun controlled by the compressor is changed, and for the non-transferred arc working mode, the following steps are included:

[0037] Step 1, install the electrode rod, disconnect all devices from the power supply, and keep the gas pressure in the atomization chamber at 1.1 bar after the gas in the atomization chamber is replaced by Ar gas;

[0038] Step 2, start the compressor to keep the gun inlet pressure at 2.5bar, set the variable resistor connected to the nozzle to be small, start the high-frequency oscillator and power supply, start the arc between the nozzle and the cathode, and the plasma flame gas passes through the Laval type The plasma gun nozzle is compressed and blown out;

[...

Embodiment 2

[0042] A method for centrifugal atomization of a dual-mode plasma arc device according to claim 1, comprising the following steps:

[0043] Step 1, install the electrode rod, disconnect all devices from the power supply, and keep the gas pressure in the atomization chamber at 1.3bar after the gas in the atomization chamber is replaced by Ar gas;

[0044] Step 2, start the compressor to keep the gun inlet pressure at 3bar, set the variable resistance connected to the nozzle to be small, start the high-frequency oscillator and power supply, start the arc between the nozzle and the cathode, and the plasma flame gas passes through the Laval type plasma The nozzle of the gun is compressed and blown out;

[0045] In step 3, the plasma gun is moved as a whole, so that the non-transferred arc impacts the end face of the bar, and the end face of the bar begins to melt under the thermal impact of the plasma flame.

[0046] When the non-transferred arc mode is selected, it is suitable f...

Embodiment 3

[0048] A method for centrifugal atomization of a dual-mode plasma arc device according to claim 1, comprising the following steps:

[0049] Step 1, install the electrode rod, disconnect all devices from the power supply, and keep the gas pressure in the atomization chamber at 1.2 bar after the gas in the atomization chamber is replaced with Ar gas;

[0050] Step 2, start the compressor to keep the gun pressure at 2.8bar, set the variable resistance connected to the nozzle to be small, start the high-frequency oscillator and power supply, start the arc between the nozzle and the cathode, and the plasma flame gas passes through the Laval type The plasma gun nozzle is compressed and blown out;

[0051] Step 3, the plasma gun is moved as a whole, so that the non-transferred arc impacts the end face of the bar, and the end face of the bar begins to melt under the impact of the thermal energy of the plasma flame.

[0052] When the non-transferred arc mode is selected, it is suitable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com