Waste heat recovery efficient energy-saving stove system

A high-efficiency, energy-saving, waste heat recovery technology, applied in water heaters/stoves, household stoves, household heating and other directions, can solve the problems of heat energy loss, unfavorable kitchen environment maintenance, large gas consumption, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

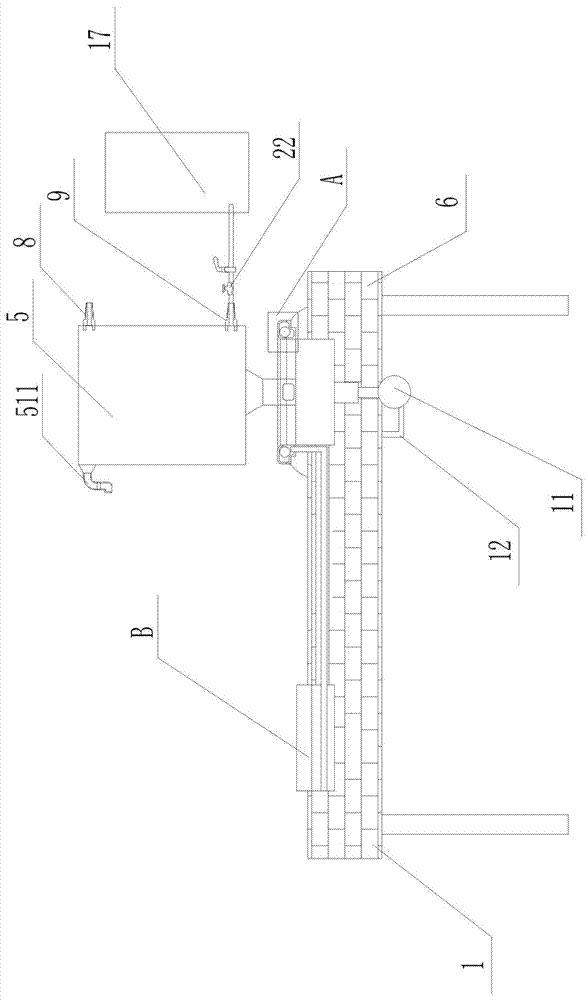

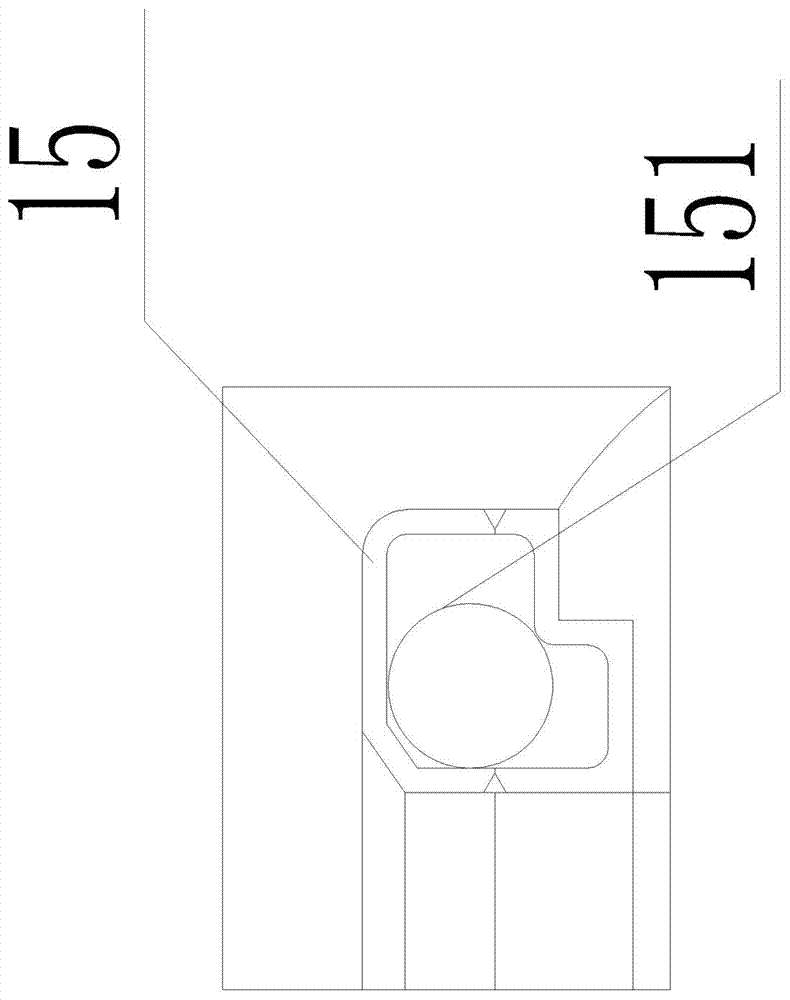

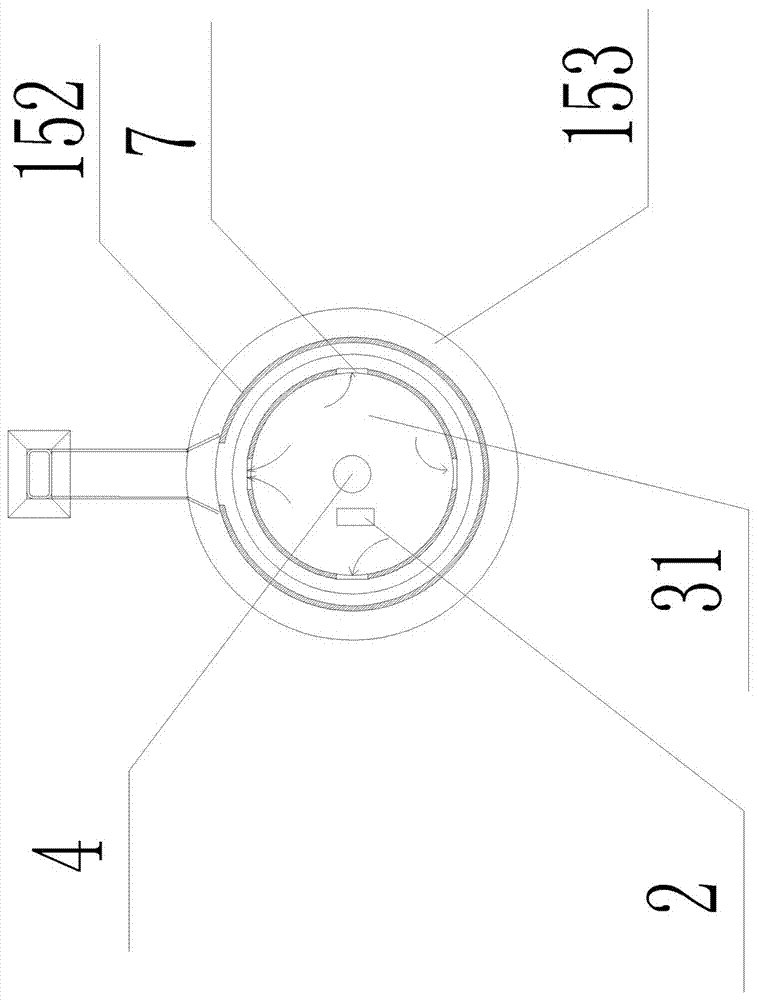

[0040] Such as Figure 1-6As shown, a waste heat recovery high-efficiency energy-saving cooker system includes a cooker body 1. The cooker body 1 includes a bracket 6, a combustion chamber 3, an ignition assembly 4 and a flue gas heat exchange assembly 5. Intake pipe, the combustion chamber 3 is embedded and installed on the bracket 6; the ignition assembly 4 is installed at the bottom of the combustion chamber 3, and the combustion chamber 3 is provided with an air inlet 2, and the air inlet 2 cooperates with the ignition The assembly 4 is set and used to provide oxygen-supplementing air to the ignition assembly 4, and the air inlet 2 is arranged close to the ignition assembly 4; the upper end of the combustion chamber 3 is provided with a vent hole 7, and the vent hole 7 communicates with the flue gas heat exchange assembly 5, and the combustion chamber Hot gas and flue gas pass into the heat exchange component 5;

[0041] The flue gas heat exchange assembly 5 includes a fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com