Online monitoring device for tunnel boring machine cutter and method thereof

A tunnel boring machine and monitoring device technology, which is applied in wireless communication, testing wear resistance, electrical components, etc., can solve problems such as lowering TBM work efficiency, improve equipment fault diagnosis efficiency, reduce engineering costs, and realize preventive The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The online monitoring device and method of the tunnel boring machine tool provided by the present invention will be described in detail below with reference to the drawings and specific embodiments.

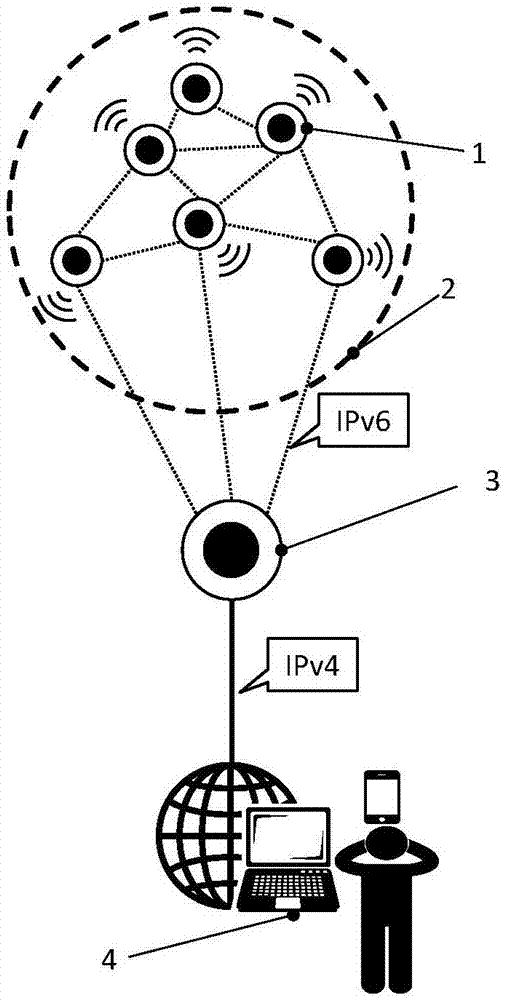

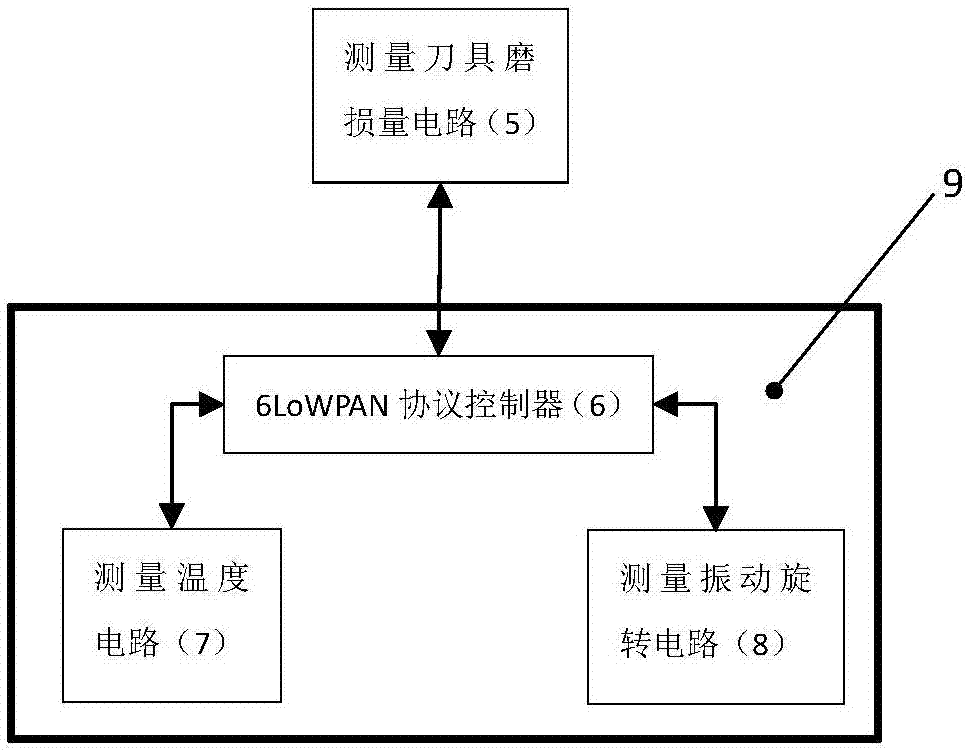

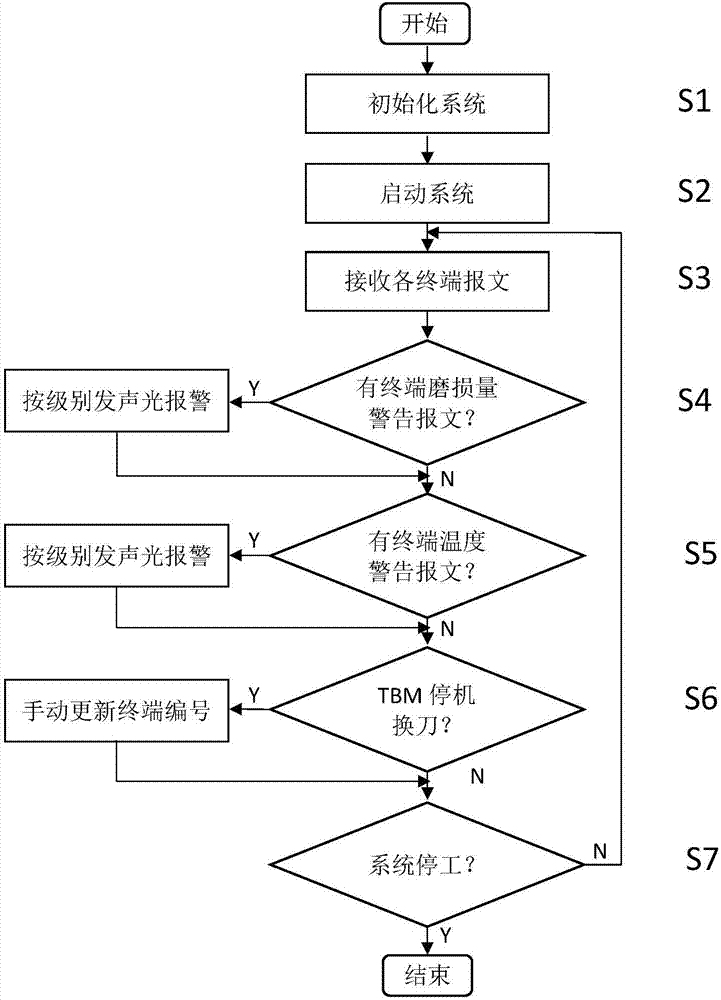

[0025] Such as figure 1 As shown, an online tool monitoring device of a tunnel boring machine of the present invention includes a background controller 4 and a cloud server, a 6LoWPAN protocol edge router 3, and several tool monitoring controllers 1 attached to the TBM cutter head tools. The said background controller 4 is a large-screen microcomputer or tablet computer. Multiple tool monitoring controllers 1 have self-organizing network function and automatically form a 6LoWPAN protocol wireless network 2. The advantage of this network is that it has a powerful self-healing function. As long as one of the multiple tool monitoring controllers 1 maintains communication with the edge router 3, all other tool monitoring controllers can send messages to the edge router 3. The edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com