Novel seedling growing container

A seedling-raising container and container technology, applied in the field of forest woody plant seedling-raising containers, can solve problems such as high cost, unreasonable shape and inner wall design, nest roots, etc., and achieve abundant fibrous roots, abundant mycorrhizal species, and easy recovery of growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

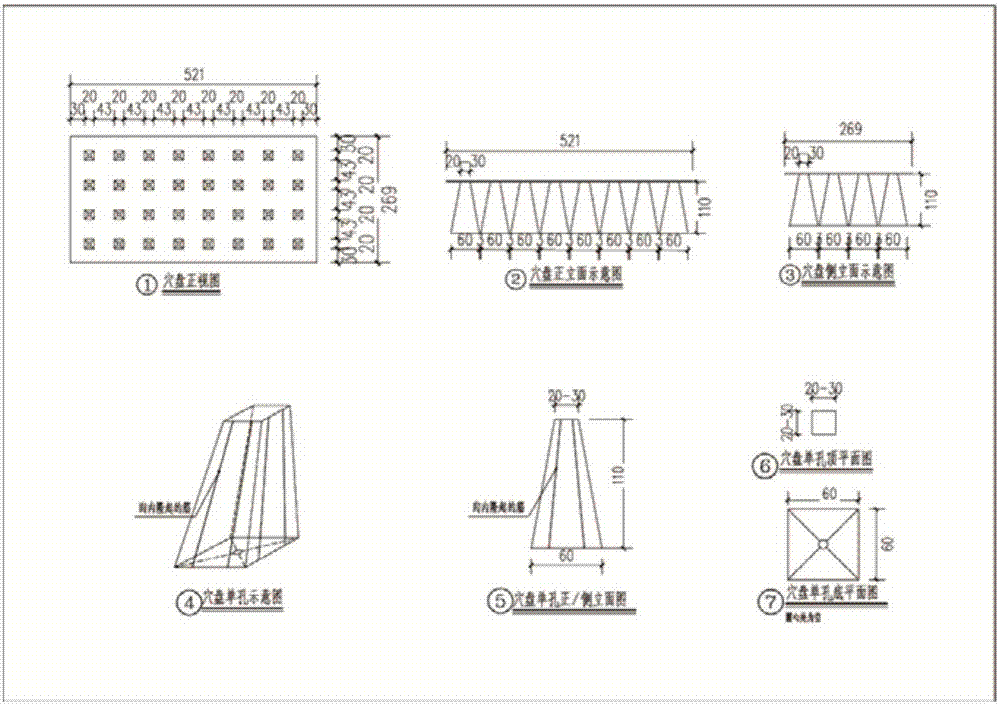

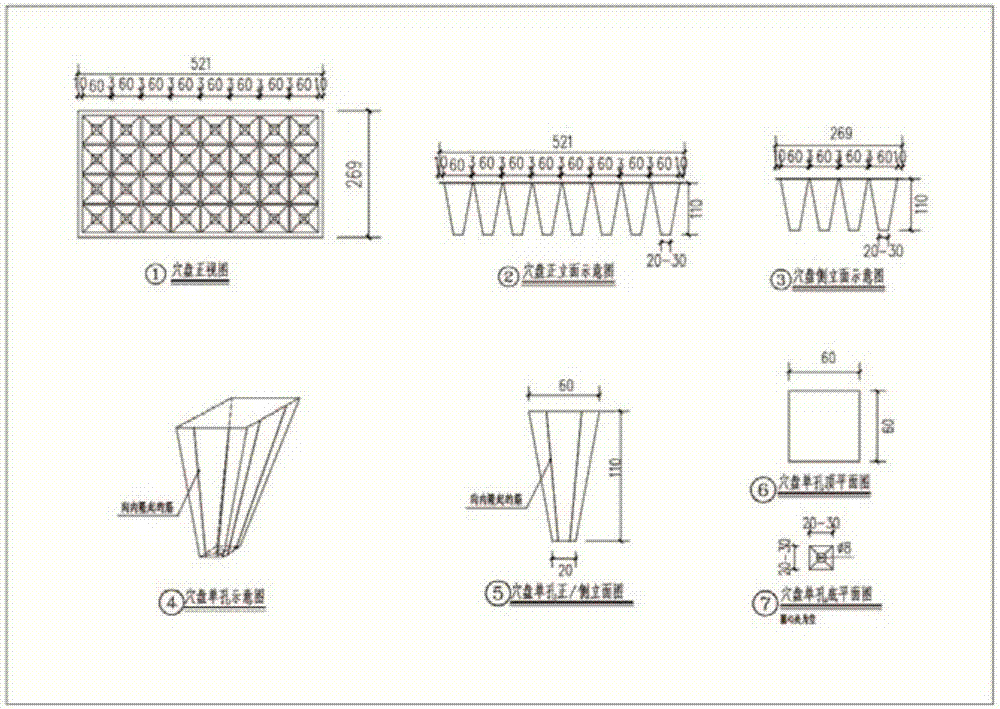

Embodiment 1

[0019] The porous combined container made of polypropylene material has the shape of a single hole: the length of the upper bottom is 3.5cm, the length of the lower bottom is 6cm, and the height of the platform is 11cm. A total of 32 combined container boxes are combined into one. After filling with a mixed matrix prepared with peat soil, vermiculite, and organic fertilizer, sow at least one healthy pine seed in each hole, water and moisturize, and inoculate Russula rufica strains after 20 days, and leave it in the greenhouse Germinate, grow, and after 200 days, the average seedling is up to 30cm, and the root system stretches without curling, and the number of mycorrhizal units reaches more than 53.

Embodiment 2

[0021] A porous combined container made of polyethylene material, the shape of a single hole is: the length of the upper bottom is 3cm, the length of the lower bottom is 5.5cm, and the height of the platform is 9cm. A total of 32 combined container boxes are combined into one. After filling with a mixed matrix prepared with peat soil, vermiculite, and organic fertilizer, at least one healthy pine seed was sown in each hole, watered and moisturized, and boletus boletus strains were inoculated 20 days later. Its natural germination, growth, after 230 days, average seedling is up to 23.5cm, and root system stretches without curling, and the number of mycorrhizal units reaches more than 74.

Embodiment 3

[0023] The porous combined container made of polypropylene material has the shape of a single hole: the length of the upper bottom is 6cm, the length of the lower bottom is 3.2cm, and the height of the platform is 10cm. A total of 32 combined container boxes are combined into one. After filling with a mixed matrix prepared with peat soil, vermiculite, and organic fertilizer, sow at least one healthy seed of Qinggang per hole, water and moisturize, and inoculate Boletus spp. strains after 20 days, and leave it in the greenhouse Germinate, grow, and after 240 days, the average seedling is up to 35cm, and the root system stretches without curling, and the number of mycorrhizal units reaches more than 45.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com