High-strength, high-size-precision and good-coaxiality accurate grinding bar cold drawing production technology

A technology of dimensional accuracy and production process, which is applied in the field of cold drawing production process of finely ground rods with high strength, high dimensional accuracy and good coaxiality, can solve the problems of bar deformation, low production efficiency, and waste products, and achieve enhanced surface Hardness and wear resistance, improvement of three-point out-of-roundness, effect of preventing bending after quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] The material is 1018 steel in ASTM A29 standard:

[0026] 1) Material selection: Select Φ36mm black leather rolling material for flaw detection one by one, the surface is inspected according to the defect depth of ≤0.3mm magnetic flux leakage flaw, the internal surface is inspected according to ASTM A388 standard FBH=1.6mm ultrasonic flaw detection, and the qualified rolled steel is cut according to the required length. The end of the rolled material is sharpened and the surface is shot blasted to prepare for cold drawing.

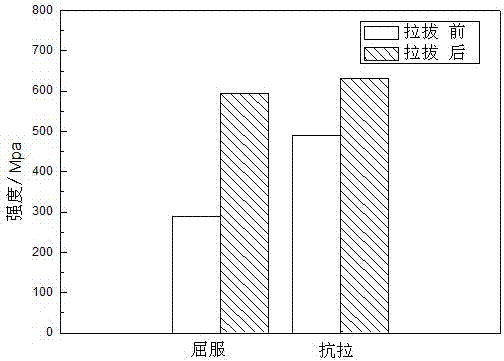

[0027] 2) Drawing: According to the mechanical performance requirements of the finished product, set the cold drawing area reduction rate to 16%, select the drawing eye mask corresponding to the aperture of Φ33mm for drawing, the drawing speed is 8m / min, and check the mechanical properties after drawing Meet Rp 0.2 ≥483Mpa, Rm≥552Mpa, A≥14% requirements.

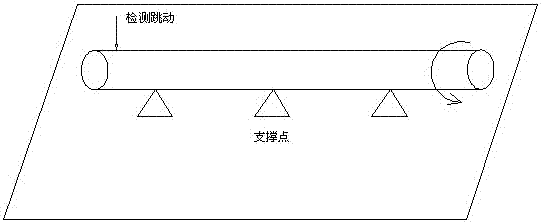

[0028] 3) Wagon and straightening: Pre-straighten the drawn material, control the straightne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com