Anti-burn double-layer co-extrusion built-in drip irrigation tape and preparation method thereof

A double-layer co-extrusion and drip irrigation tape technology, which is applied in the direction of botany equipment and methods, chemical instruments and methods, layered products, etc., can solve the problems of economic loss, affecting crop growth, uneven irrigation in the field, etc., and prolong the service life , improve the anti-burn ability, increase the effect of transverse strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

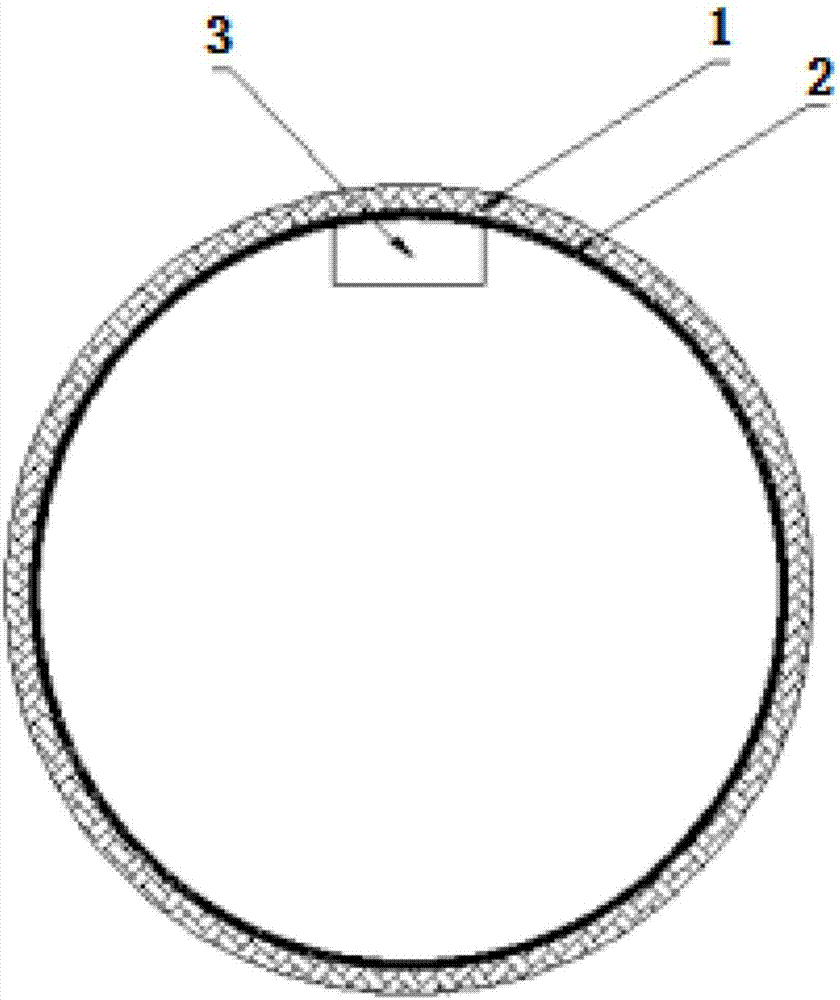

[0026] An anti-burn double-layer co-extruded inlaid drip irrigation tape, the drip irrigation tape includes an inner layer 2 and an outer layer 1; the inner layer is prepared from components including the following mass fractions: high-density polyethylene 40%, 30% of low-density polyethylene, 20% of linear low-density polyethylene, 2% of multi-functional masterbatch, 8% of silver masterbatch; the outer layer is prepared from each component comprising the following mass fractions: the outer layer is Prepared from various components including the following mass fractions: 60% of high-density polyethylene, 1% of AC foaming system, 2% of DCP crosslinking system, 30% of linear low-density polyethylene, and 4% of silver masterbatch; Concentrated masterbatch prepared by AC foaming system and DCP crosslinking system.

[0027] Furthermore, the multifunctional masterbatch is PPA, a fluoropolymer processing aid.

[0028] Furthermore, the AC foaming system is composed of azodicarbonamid...

Embodiment 2

[0042] An anti-burn double-layer co-extrusion inlaid drip irrigation tape, the drip irrigation tape includes an inner layer 2 and an outer layer 1; the inner layer is prepared from components including the following mass fractions: high-density polyethylene 50%, 20% of low-density polyethylene, 25% of linear low-density polyethylene, 1% of multifunctional masterbatch, 5% of silver masterbatch; the outer layer is prepared from each component comprising the following mass fractions: the outer layer is Prepared from various components including the following mass fractions: 70% of high-density polyethylene, 2% of AC foaming system, 1% of DCP crosslinking system, 21% of linear low-density polyethylene, and 3% of silver masterbatch; Concentrated masterbatch prepared by AC foaming system and DCP crosslinking system.

[0043] Furthermore, the multifunctional masterbatch is PPA, a fluoropolymer processing aid.

[0044] Furthermore, the AC foaming system is composed of azodicarbonamide,...

Embodiment 3

[0058] An anti-burn double-layer co-extrusion inlaid drip irrigation tape, the drip irrigation tape includes an inner layer 2 and an outer layer 1; the inner layer is prepared from components including the following mass fractions: high-density polyethylene 60%, 25% of low-density polyethylene, 10% of linear low-density polyethylene, 1% of multifunctional masterbatch, 4% of silver masterbatch; the outer layer is prepared from each component comprising the following mass fractions: the outer layer is Prepared from various components including the following mass fractions: 75% of high-density polyethylene, 1% of AC foaming system, 1% of DCP crosslinking system, 13% of linear low-density polyethylene, and 8% of silver masterbatch; Concentrated masterbatch prepared by AC foaming system and DCP crosslinking system.

[0059] Furthermore, the multifunctional masterbatch is PPA, a fluoropolymer processing aid.

[0060] Furthermore, the AC foaming system is composed of azodicarbonamid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com