Needle tube type flue gas heating device

A flue gas heating and needle-shaped tube technology, which is used in the design and manufacture of corrosion-resistant needle-shaped tubes, and the field of steel tube-and-tube type flue gas heating devices, can solve the problems of unfavorable smoke diffusion, aggravated photochemical smog, etc., and achieves good sealing effect. , Good wear resistance and corrosion resistance, and the effect of increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

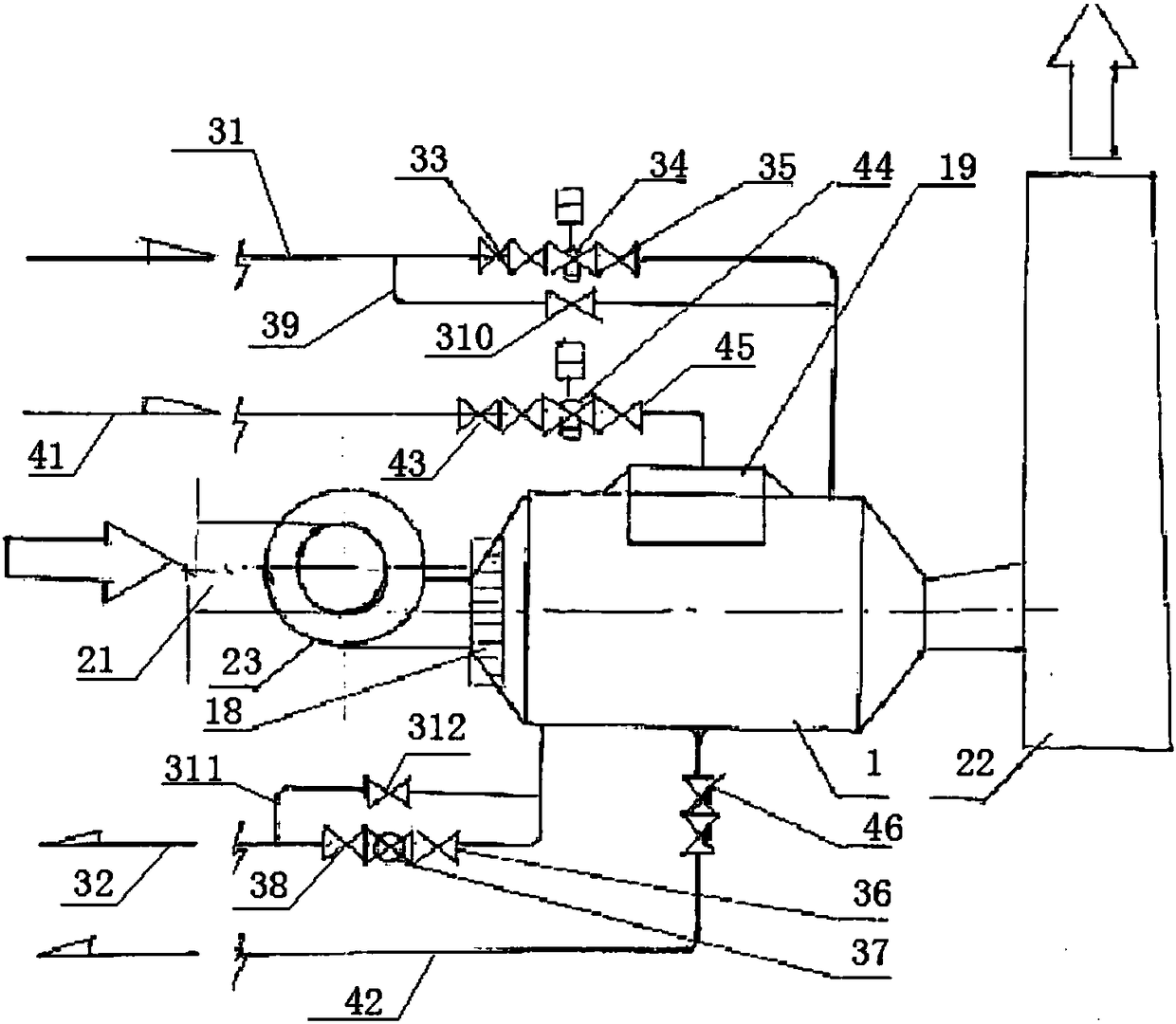

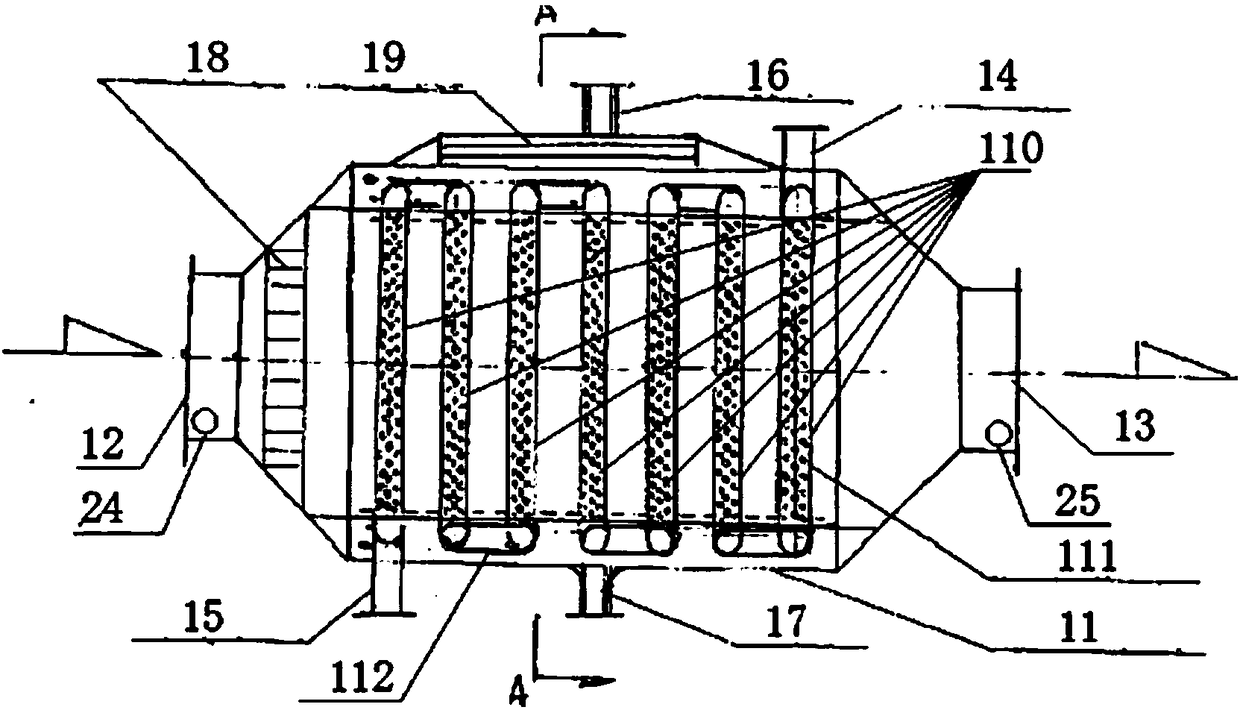

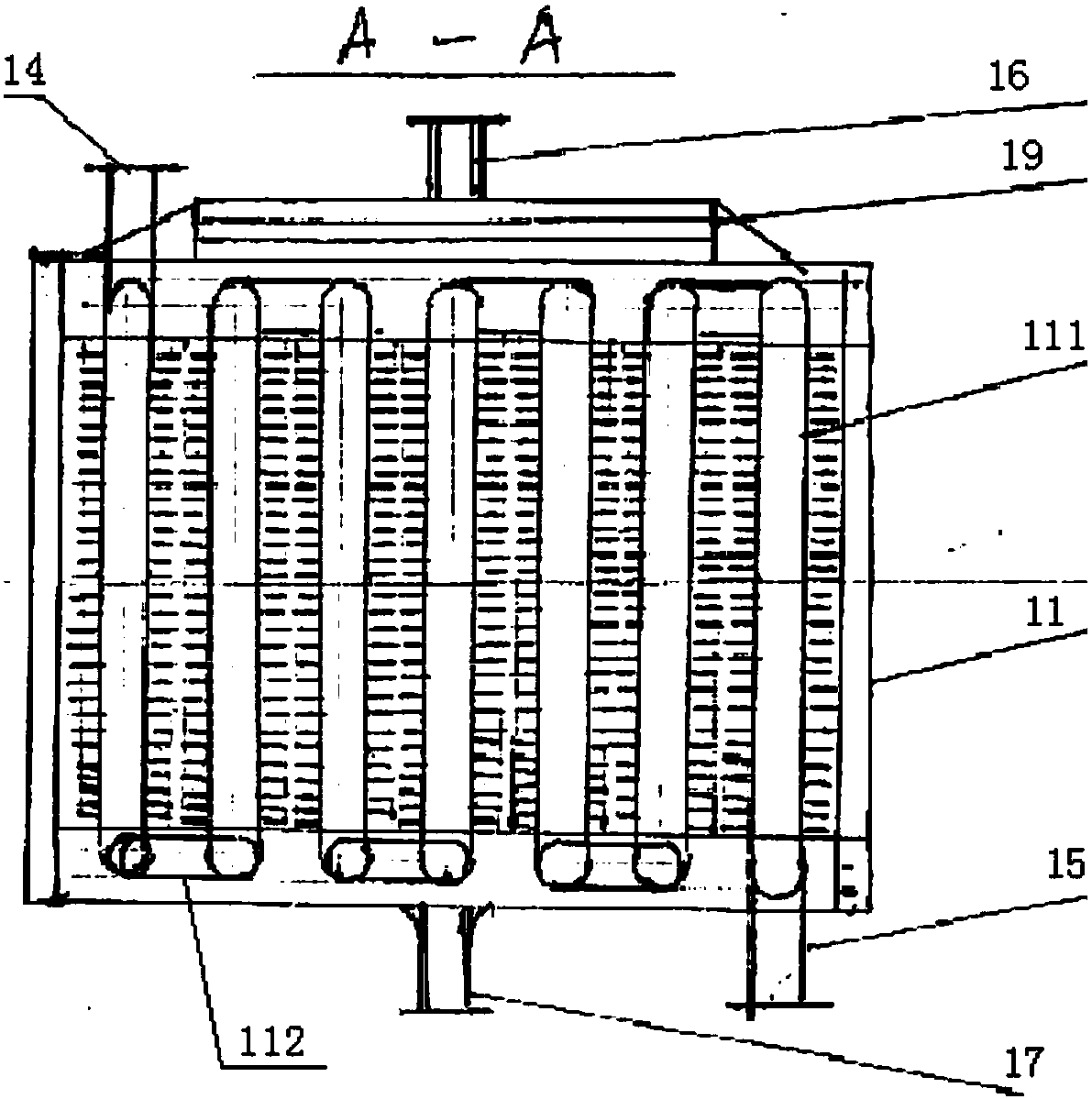

[0046] Embodiment: A needle-shaped tube type flue gas heating device, such as figure 1 with Figure 5 As shown, it includes a heater 1, a flue gas system, a steam system and a needle tube group cleaning system, and the flue gas system, the steam system and the needle tube group cleaning system all pass through the heater;

[0047] The shell 11 of the heater 1 has a flue gas inlet 12, a flue gas outlet 13, a steam inlet 14, a condensed water outlet 15, a cleaning water inlet 16 and a sewage outlet 17, the flue gas inlet communicates with the flue gas outlet, The steam inlet communicates with the condensed water outlet, and the cleaning water inlet communicates with the sewage outlet;

[0048] The smoke inlet is connected to the smoke inlet pipe 21, the smoke outlet is connected to the smoke exhaust pipe 22, the smoke inlet pipe or the smoke exhaust pipe is provided with an induced draft fan 23, and the inlet of the smoke gas is provided with an inlet pressure sensor 24. An ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com