Ecological water oxygen paint and preparation method thereof

An ecological and coating technology, applied in coatings and other directions, can solve problems such as chemical pollution and microbial pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

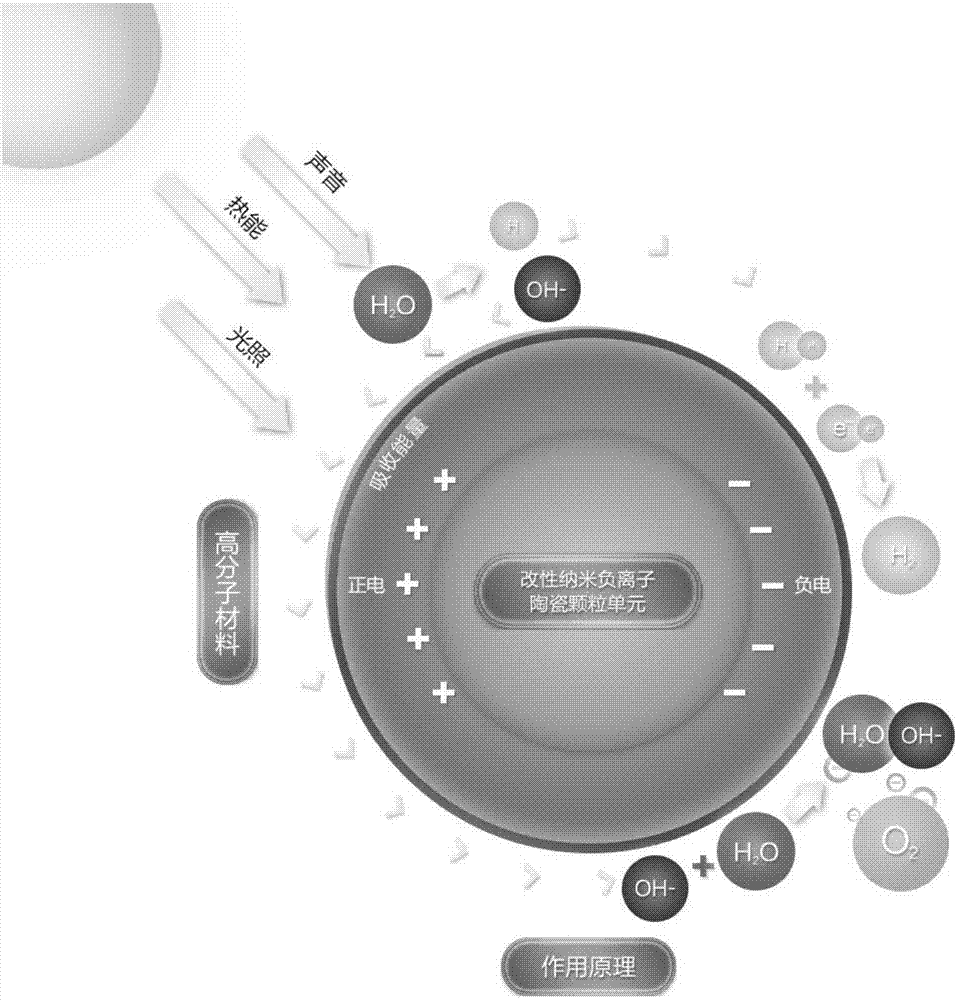

Method used

Image

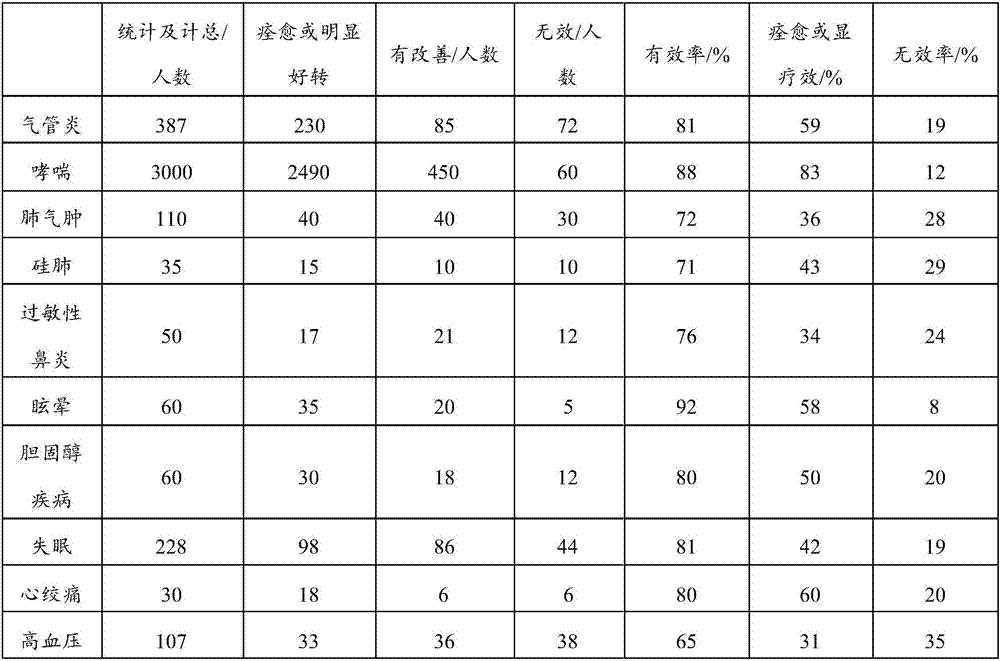

Examples

preparation example Construction

[0090] The present invention also provides a method for preparing the above-mentioned water-oxygen ecological paint, comprising: S1) mixing 25-35 parts by weight of water-based acrylic resin with 25-35 parts by weight of water to obtain the first solution; S2) mixing part of the second One solution, 5-15 parts by weight of negative ion ceramic particles and 0.1-0.15 parts by weight of graphene oxide aqueous solution are mixed to obtain a second solution; the concentration of the graphene oxide aqueous solution is 50-500 mg / L; S3) the remaining The first solution, 0.03-0.06 parts by weight of zinc oxide, 0.3-1.8 parts by weight of nano-rare earth mineral powder and 1-1.5 parts by weight of hydroxyethyl cellulose are mixed to obtain a third solution; S4) the second solution is Mix with the third solution to get the water-oxygen ecological paint.

[0091] Wherein, the water-based acrylic resin, water, negative ion ceramic particles, graphene oxide aqueous solution, zinc oxide, na...

Embodiment 1

[0103] 1.1 Pour 25 parts by weight of water-soluble resin into 35 parts by weight of deionized water and stir for 30 minutes at a speed of 1000 rpm to obtain a water-based acrylic resin solution.

[0104] 1.2 Divide 7 parts by weight of polyethylene glycol emulsifier (PEG1450 type) into 5 equal parts, and slowly pour them into the water-based acrylic resin solution in batches with an interval of 10 minutes. After adding, stir for 30 minutes at a speed of 2000 rpm minutes; Emulsion A was formed.

[0105] 1.3 Get 20% of the volume of emulsion A, pour it into a homogenizer, add 14 parts by weight of modified negative ion nano-ceramic unit particles (N90 particle diameter 200 nanometers), stir for 20 minutes, and the speed is 4000 rpm to make emulsion B .

[0106] 1.4 Add 4 parts by weight of photocatalyst (anatase nano-titanium oxide, VK-G01, N90 particle size 10 nanometers) and 0.1 parts by weight of graphene oxide aqueous solution with a concentration of 100 mg / L to emulsion B...

Embodiment 2

[0125] The consumption of modified negative ion nano-ceramic unit particle is changed into 8 weight parts by 14 weight parts among the embodiment 1; Nano rare earth ore powder is changed into 0.6 weight parts by 1.2 weight parts; Other composition and production process are constant, obtain water Oxygen Ecological Paint.

[0126] The water-oxygen ecological coating obtained in Example 2 is coated with a thickness of 0.1 to 0.2 mm. After construction, it is ventilated and dried for seven days. The test results are as follows:

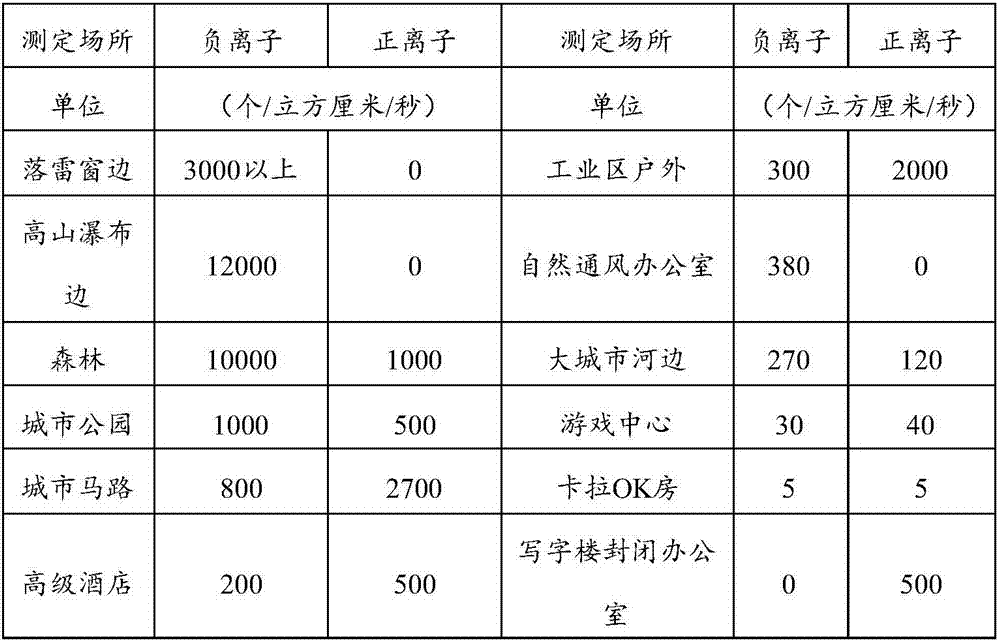

[0127] Wall detection: The concentration of ecological negative ions reaches 10,000 / cubic centimeter / second;

[0128] Indoor space (1500 cm away from the wall): the concentration of ecological negative ions reaches 1500-2000 / cubic centimeter / second;

[0129] Detection conditions: humidity 60%, temperature 20 degrees Celsius; light conditions: sunny.

[0130] The far-infrared wavelength released by the water-oxygen ecological paint coating obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com